DTF transfers, or Direct-to-Film transfers, have revolutionized the world of textile printing, providing an innovative way for creators to produce vibrant designs that stand out. This cutting-edge printing method streamlines the process of transferring intricate artworks onto fabric, making it an ideal choice for custom apparel and promotional items. By utilizing DTF transfers, designers can achieve high-quality prints that bond seamlessly with a variety of textiles, opening the door to endless creative possibilities. In this article, we’ll delve into essential techniques and tips that will enhance your DTF printing skills, ensuring that every project exceeds expectations. Get ready to explore the exciting realm of heat transfer methods that can transform your designs into eye-catching masterpieces.

Known also as Direct-to-Film printing, DTF transfers have become a preferred choice in the textile printing industry, thanks to their versatility and ability to deliver detailed and colorful outputs. This innovative process allows for custom designs to be printed onto a specialized film which is then heat-transferred onto a wide range of fabrics. As we discuss the various aspects of this printing method, including techniques and best practices, you’ll see why many designers are integrating DTF technology into their workflows. With the exploration of various heat transfer methods and guidelines for achieving vibrant prints, this guide will support both novices and seasoned professionals alike in mastering Direct-to-Film printing.

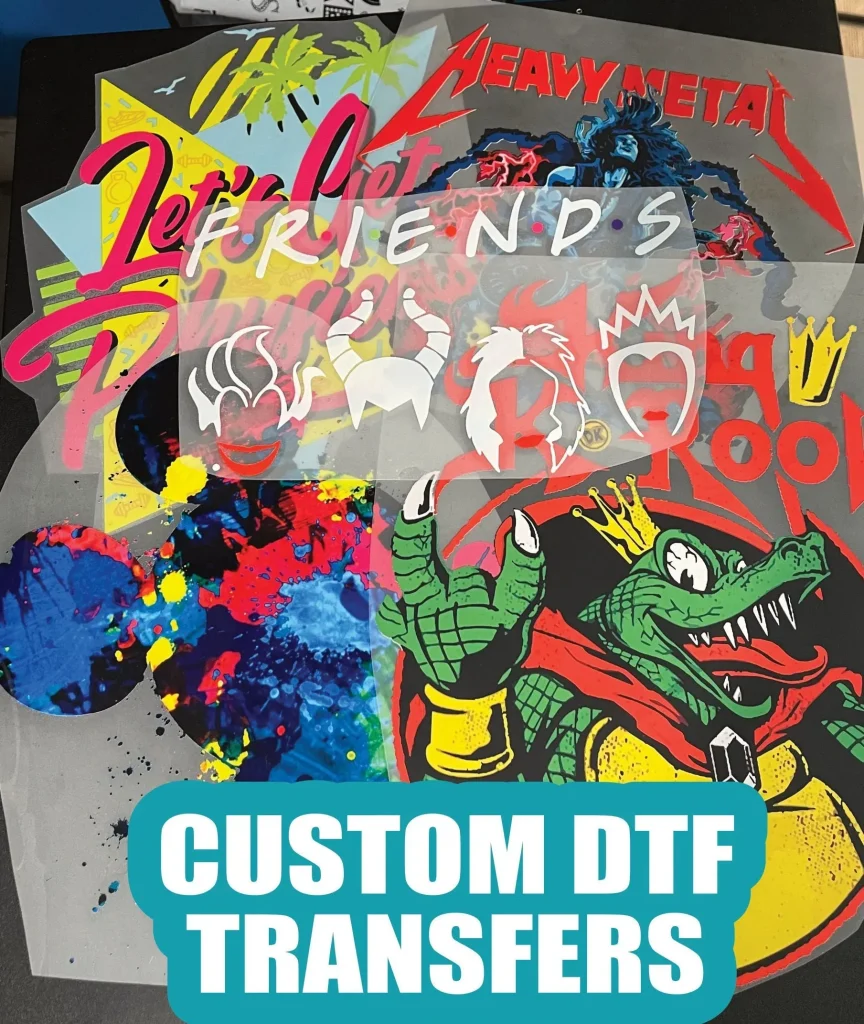

Understanding the Benefits of DTF Transfers

DTF transfers have revolutionized the way we approach custom apparel and textile printing, providing a diverse range of benefits for both designers and businesses. One of the most significant advantages is the ability to produce vibrant designs that maintain their quality over time. DTF technology allows for deep penetration of inks into the substrate, ensuring that colors not only pop but also remain durable after repeated washes. This makes DTF an ideal solution for fashion brands seeking to deliver high-quality products that stand out in a crowded market.

Another key benefit of using DTF transfers is the versatility they offer. Unlike traditional heat transfer methods, which can be limited to specific types of fabrics, DTF transfers can be applied to a wide variety of textiles including cotton, polyester, and even blends. This ability to print on multiple surfaces widens the scope of creative possibilities for designers, enabling them to experiment with various materials and applications, from custom apparel to promotional merchandise.

Essential Techniques for Successful DTF Printing

To succeed in DTF printing, certain techniques must be mastered that enhance the overall quality of your output. First and foremost, ensure that the design files used are high-resolution. When working with graphics and artwork, using vector files or high-resolution images is crucial to avoid pixelation during the printing process. This attention to detail guarantees that the vibrant designs you’re aiming to create translate effectively onto the final product.

Furthermore, understanding the curing process of the adhesive is vital for achieving durable prints. The adhesive not only helps bond the ink to the textile but also plays a critical role in the overall longevity of the design. It’s essential to follow manufacturer guidelines closely in terms of temperature and timing for curing the adhesive. Neglecting this step can lead to transfers that fade or peel away after a few washes, compromising the quality of your custom apparel.

Color Management Strategies for DTF Printing

Color management is an integral part of DTF printing, as it directly influences the vibrancy and accuracy of the designs. Utilizing ICC profiles tailored for your specific printer and ink setup is a crucial step in ensuring true-to-life color reproduction. These profiles allow for precise adjustments that align your designs with the final output, greatly diminishing the risk of color discrepancies that can occur during printing.

Additionally, pre-testing your colors on your selected fabric is highly recommended. By printing samples and observing how the colors appear on various textiles, you can make necessary adjustments to your original designs. This practice can prevent unexpected surprises when you finalize your projects, resulting in high-quality, visually appealing custom apparel that meets your clients’ expectations.

Choosing the Right Film for DTF Transfers

Selecting the correct film for your DTF transfers can significantly impact the quality of your prints. The film you choose should complement your printer capabilities and the types of designs you intend to create. Opt for films specifically designed for DTF printing, as these will offer better adhesion and image clarity, ensuring your vibrant designs maintain their integrity.

Moreover, compatibility with your heat press is another vital consideration. Different films can have varying requirements for heat and pressure settings. Conducting thorough research and trying out different products will help you identify the right film that produces optimal results for your specific projects, enhancing both efficiency and quality in your DTF printing endeavors.

Heat Press Techniques for Optimal DTF Printing

Heat press techniques are critical to achieving optimal results in DTF printing and ensuring that your vibrant designs are properly transferred onto the fabric. It’s essential to experiment with various settings to identify the ideal temperature and pressure suited for your specific type of textile. For instance, synthetic fabrics may require different settings compared to cotton, so understanding the material’s characteristics is key.

Additionally, timing plays a crucial role in the pressure application. Too little time can result in incomplete transfers, while excessive heat exposure may scorch the fabric or distort your design. Keeping a detailed log of your settings and the outcomes will allow you to refine your approach, leading to consistent, high-quality prints every time.

Caring for DTF Transfers to Ensure Longevity

Once your vibrant DTF designs are printed, offering proper care instructions is paramount to maintaining their appearance over time. Including specific washing guidelines with your custom apparel can significantly prolong the life of the prints. It’s advisable to recommend cool-water washing and air drying to preserve the colors and prevent fading or peeling.

In addition to washing instructions, advising clients against using bleach or harsh detergents can contribute to the durability of the transfers. Providing these care details not only enhances customer satisfaction but also reinforces the quality assurance of your products, demonstrating a commitment to delivering exceptional custom apparel.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a revolutionary method in textile printing that allows designers to print vibrant designs onto a special film. The process involves printing the image, applying a powder adhesive, curing the adhesive, and then using a heat press to transfer the design onto a variety of fabrics. This method is particularly favored for custom apparel due to its durability and high-quality print results.

How do I prepare my designs for DTF printing?

Preparing your designs for DTF printing involves ensuring you use high-resolution artwork that is compatible with the fabric type you plan to print on. Consider the texture and heat reaction of the fabric, and make adjustments to your design to ensure a successful print. Using appropriate ICC profiles will also aid in achieving accurate color reproduction for vibrant designs.

What tips can improve my DTF transfer results?

To enhance your DTF transfer results, select the right type of film that matches your printer’s specifications and resolution requirements. Additionally, experiment with the heat press settings—temperature and pressure—based on the fabric type to find an optimal balance. Following proper curing practices for the adhesive is also crucial to maintaining design durability.

Why is color management important in DTF printing?

Color management is essential in DTF printing to ensure that the final product matches the designer’s vision. Utilizing ICC profiles specific to your printer and ink can greatly improve color accuracy, preventing surprises when printing. This attention to color fidelity adds to the overall quality of custom apparel and enhances consumer satisfaction.

What are the advantages of using DTF printing for custom apparel?

DTF printing offers numerous advantages for custom apparel, including the ability to produce vibrant designs with high detail and durability. The method is suitable for various fabric types, and the prints can withstand multiple washes without fading or peeling. Furthermore, the DTF process has become more efficient due to advancements in technology, making it accessible even for beginners.

How should I care for garments printed with DTF transfers?

To maintain the vibrancy of DTF transfers, it’s important to provide proper care instructions. Recommend washing the garments in cold water and avoiding harsh detergents. Use mild wash settings and allow for air drying when possible to prolong the life of the printed designs. Following these guidelines helps ensure that the vibrant designs remain intact over time.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | Innovative textile printing method using printed designs on special film with adhesive and heat press. |

| Techniques for DTF Transfers | 1. Design Preparation: Use high-resolution artwork and consider fabric compatibility. 2. Color Management: Use ICC profiles for accurate color reproduction. 3. Curing Adhesive: Follow guidelines for temperature and time to ensure durability. |

| Tips for Successful DTF Printing | 1. Choose the Right Film: Ensure compatibility with your printer. 2. Heat Press Settings: Experiment for optimal temperature and pressure. 3. Care Instructions: Provide guidelines to maintain transfer vibrancy. |

| Recent Developments in DTF Technology | – New printer models improve color brightness and wash durability. – Pre-treated films simplify the DTF process, enhancing beginner accessibility. |

Summary

DTF transfers represent an innovative approach to creating vibrant designs that stand out in the textile printing industry. By grasping the foundational techniques and tips outlined in this guide, from effective design preparation to precise heat press settings, you can significantly enhance your printing capabilities. With the ongoing advancements in DTF technology, including improved inks and pre-treated films, now is the perfect time to explore how DTF transfers can transform your creative projects into professional-quality apparel and promotional items.