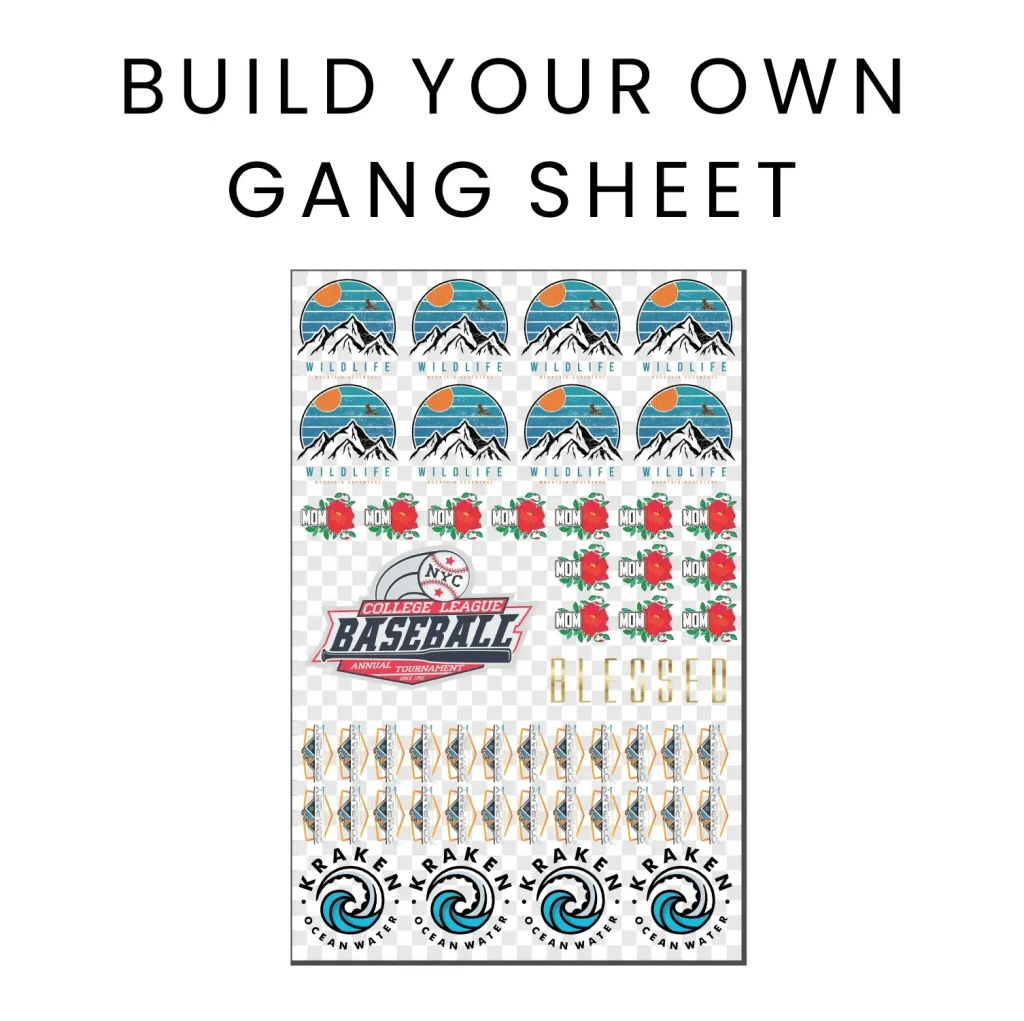

The DTF gangsheet builder is revolutionizing how custom garment printing operations handle their workflow, providing essential tools for enhancing production efficiency. By utilizing Direct-to-Film (DTF) printing technology, printers can streamline their processes and minimize waste—key factors in today’s competitive market. The gangsheet builder facilitates optimized layouts that allow for multiple designs to be printed simultaneously, thus saving valuable time and resources. As sustainability becomes paramount in printing practices, this builder not only boosts printing efficiency but also aligns with eco-friendly initiatives. In this article, we’ll delve deeper into the DTF gangsheet builder, exploring its features, advantages, and how it fosters sustainable printing practices.

The Direct-to-Film gangsheet creation tool is an innovative platform designed to enhance the efficiency of custom apparel decoration. By maximizing space on transfer films, this tool allows for the combination of multiple graphics, thereby streamlining the printing approach. With the growing emphasis on environmentally responsible methods in the printing industry, utilizing such a gangsheet builder can significantly reduce material consumption and waste. This software supports advanced DTF printing techniques that empower designers and printers to produce high-quality results while adhering to sustainable practices. Overall, exploring the capabilities of a DTF gangsheet builder reveals its important role in optimizing workflows and promoting eco-friendly solutions.

Understanding the Basics of DTF Printing Technology

Direct to Film (DTF) printing technology represents a significant advancement in the custom garment industry, offering a blend of efficiency and quality that surpasses traditional methods. DTF enables printing vibrant designs directly onto a film that can be easily applied to a variety of fabrics. This technology stands out due to its versatility, allowing intricate designs to stand out on dark and light fabrics alike while ensuring that colors remain vivid. As printers adapt to DTF, understanding its operational framework becomes essential for optimizing results.

Furthermore, DTF technology fosters printing efficiency by reducing production time. Unlike screen printing, which requires separate setups for each color, DTF printing can print multiple colors in a single pass. This reduction in setup times not only speeds up the printing process but also allows for more complex designs to be executed seamlessly. Therefore, adopting DTF printing technology signifies a commitment to innovation and quality in custom garment production.

What is a DTF Gangsheet Builder and Its Importance?

A DTF gangsheet builder is an indispensable tool for printers looking to maximize their production efficiency. By optimizing layouts for multiple designs on a single transfer sheet, it streamlines the workflow significantly. Printers can make the most of each sheet, minimizing waste while producing high volumes of prints. This is crucial not only from an economic perspective but also for promoting sustainable practices within the industry, as reducing material waste is a growing concern.

The importance of a DTF gangsheet builder extends beyond cost-saving benefits. It enhances creativity by allowing designers to visualize and manipulate their layouts easily. This flexibility enables printers to experiment with combinations of designs and sizes, leading to unique offerings. By leveraging such tools, businesses can increase the variety of products they offer without incurring additional setup costs, thus catering to a broader customer base.

Key Features for Enhancing Printing Efficiency

Modern DTF gangsheet builders come equipped with a range of features designed to boost printing efficiency. Automated nesting is one of the most significant advancements in these tools, allowing users to automatically arrange multiple designs on transfer sheets to maximize usage. This feature not only minimizes waste but also saves valuable time that would otherwise be spent manually arranging layouts. With better space utilization, printers can benefit from increased output, aligning with cost-effectiveness.

Moreover, user-friendly interfaces of these software programs make them accessible to users with various skill levels. Intuitive designs allow even those unfamiliar with DTF technology to adapt quickly and create optimized layouts. This ease of use is particularly beneficial for small businesses aiming to enhance their operations without investing heavily in training or onboarding personnel. As a result, the integration of these features can significantly streamline the printing process, leading to enhanced production capabilities.

Techniques for Optimizing DTF Printing Workflow

To fully leverage the capabilities of a DTF gangsheet builder, one must adopt certain techniques that enhance the overall printing workflow. Creating optimized layouts before initiating the printing process can drastically reduce material waste. Analyzing how designs fit together using the software can reveal opportunities for adjustments that improve overall efficiency. Implementing such practices leads to not only savings in materials but also the timely execution of orders.

In addition, using high-quality materials plays a crucial role in refining the DTF printing process. Quality transfer films ensure better adhesion to fabrics and increase durability, resulting in fewer reprints and wasted resources. Regular testing should also be a staple in your workflow; it allows printers to make adjustments as needed, maintaining high standards for output while optimizing settings for peak efficiency. Staying updated with technological advancements in DTF will further refine these workflows, leading to continual improvement and productivity.

Understanding the Role of Sustainability in DTF Printing

As sustainability emerges as a priority across industries, incorporating eco-friendly practices into DTF printing is vital. The capability of DTF technology to produce high-quality prints with minimal material waste stands in stark contrast to many traditional methods. By utilizing a DTF gangsheet builder, printers can ensure that they operate in a manner that aligns with sustainable values, thus appealing to environmentally-conscious consumers.

Moreover, understanding the environmental impact of DTF printing can position brands favorably in the market. By actively promoting sustainable practices, such as minimizing waste and utilizing eco-friendly inks, businesses not only contribute to a healthier planet but also attract a growing demographic of consumers who prioritize sustainability over convenience. Effective communication about these practices can enhance brand loyalty and foster a positive public image.

Future Trends in DTF Printing Technology

The landscape of DTF printing technology is rapidly evolving, and keeping up with the latest trends is crucial for printers aiming for long-term success. Innovations such as water-based inks and advancements in printing machinery are setting the stage for a greener future within the industry. As more businesses strive for eco-friendly solutions, embracing these innovations will not only enhance printing efficiency but also align operations with current sustainability goals.

Additionally, real-time data analytics and smart technology integration are reshaping how printers approach production efficiency. By utilizing analytics, businesses can refine their processes by assessing every stage of production, allowing for timely adjustments based on performance metrics. This data-driven approach ensures that printers not only remain competitive but also remain ahead of the curve in efficiency and sustainability. Future developments in DTF printing technology promise to reshape the industry, and staying abreast of these changes can significantly benefit businesses.

Frequently Asked Questions

What advantages does a DTF gangsheet builder offer for Direct-to-Film printing?

A DTF gangsheet builder maximizes efficiency by optimizing layout designs for Direct-to-Film printing. It automates the nesting of images, ensuring minimal waste and higher output per transfer sheet, which leads to cost savings and improved productivity.

How does gangsheet optimization enhance sustainability in DTF printing technology?

Gangsheet optimization in DTF printing technology reduces material waste by fitting multiple designs onto a single sheet efficiently. This practice aligns with sustainable printing practices by lowering resource consumption and minimizing environmental impact.

What features should I look for in a DTF gangsheet builder software?

When choosing a DTF gangsheet builder, look for features such as automated nesting, user-friendly interfaces, compatibility with various DTF printers, and support for high-quality transfer films, all of which enhance printing efficiency and output quality.

Can a DTF gangsheet builder improve printing efficiency for small businesses?

Yes, a DTF gangsheet builder can greatly improve printing efficiency for small businesses by allowing them to create optimized layouts quickly. This leads to reduced material waste and faster production times, making it an ideal tool for scaling operations.

What role does technology play in maximizing DTF printing efficiency with gangsheet builders?

Technology plays a crucial role in maximizing DTF printing efficiency by providing advanced features in gangsheet builders, such as automated image placement and real-time optimization suggestions, which streamline the printing process and reduce time spent on layout adjustments.

How can staying updated with DTF printing technology benefit operations using a gangsheet builder?

Staying updated with DTF printing technology enhances operations by ensuring access to the latest tools and features in gangsheet builders, which can improve layout efficiency and adapt to new sustainable practices, ultimately leading to better production outcomes.

| Key Aspects | Details |

|---|---|

| Understanding DTF Technology | DTF is a modern method for custom garment printing that allows vibrant designs on various fabrics. |

| What is a DTF Gangsheet Builder? | A tool that optimizes layout for multiple designs on transfer sheets, reducing waste and enhancing efficiency. |

| Key Features | 1. Automated Nesting 2. Sustainability 3. User-Friendly Interfaces 4. Compatibility with Various Printers |

| Techniques for Maximizing Efficiency | – Create Optimized Layouts – Use High-Quality Materials – Test Regularly – Stay Updated with Technology |

| The Role of Sustainability | DTF technology enhances eco-friendly practices by reducing waste compared to traditional methods. |

Summary

The DTF gangsheet builder is essential for printers looking to maximize efficiency in their garment printing processes. By utilizing this innovative tool, you can optimize layouts, reduce material waste, and ultimately enhance the quality of your prints. With techniques like automated nesting and high-quality materials, a DTF gangsheet builder not only streamlines production but also aligns with the growing consumer demand for sustainability. As you navigate the evolving landscape of DTF printing, adopting these practices will set you apart in a competitive market.