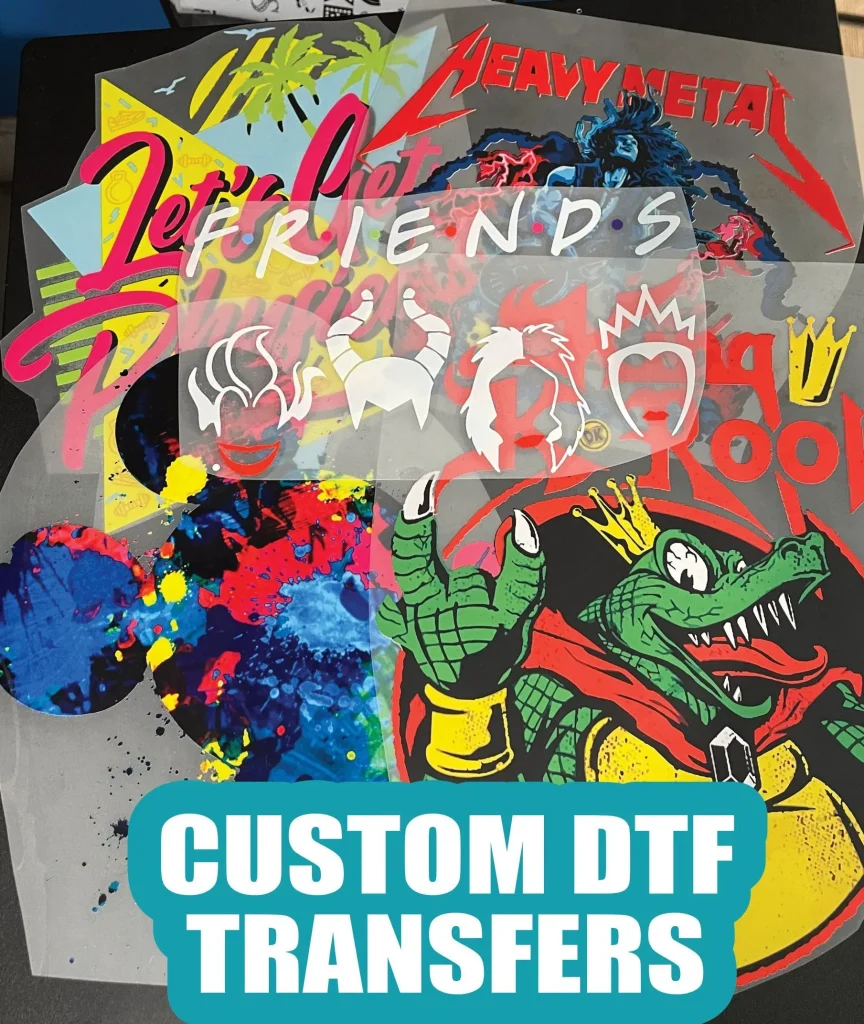

DTF transfers, or Direct to Film transfers, represent a revolutionary technique in the world of garment printing that delivers stunning results with impressive durability. This printing method is garnering attention for its ability to produce high-resolution images on a variety of fabrics, making it a favorite among designers and printers alike. In this article, we will share key insights and DTF transfer tips that will help you navigate the complexities of this process. From utilizing high-quality DTF materials to perfecting your printer settings, these best practices for DTF printing will enhance your output quality significantly. By incorporating these strategies, you can elevate your craft and ensure your DTF transfers effectively meet market demands.

Direct to Film printing offers an innovative approach to fabric decoration that combines ease of use with exceptional results. Often referred to as DTF printing, this method allows for high-quality imagery to be transferred directly onto garments, appealing to both new and experienced printers. As you delve into the world of DTF transfers, it’s essential to understand the technical aspects, such as optimal printing techniques and the significance of adhesive strength. This guide will outline essential tips on achieving successful results, encompassing everything from selecting the right printing materials to managing the printing environment effectively. Whether you’re seeking to refine your skills or initiate your printing journey, these insights are designed to support your DTF printing endeavors.

Understanding DTF Printing Techniques

DTF printing techniques are essential to grasp for anyone looking to enhance their garment printing capabilities. This method stands out due to its ability to deliver high-quality prints with vibrant colors on various fabric types. At the core of this technology is the process involving special transfer films and inks that bond well with fabrics when subjected to heat. Mastering these techniques allows printers to achieve striking designs that not only look good but are also durable over time.

To implement effective DTF printing techniques, understanding the entire workflow is crucial. This includes selecting the correct type of film, adjusting ink density, and ensuring that heat press settings are aligned with the specific materials in use. Additionally, experimenting with different print resolutions can significantly impact the detail and quality of final products, making technique mastery pivotal for successful DTF transfers.

Selecting High-Quality DTF Materials

Selecting high-quality DTF materials is one of the foundational aspects that dictate the success of your printing endeavors. The type of transfer film and ink used affects not only the vibrancy of the print but also its longevity on the fabric. High-quality DTF films typically feature a balance of transparency and thickness, which enhances the vibrancy and durability of the prints. Moreover, using reputable brands for your inks ensures that the colors remain bright even after multiple washes, preventing wear and fading.

In addition to transfer films and inks, the choice of adhesive powders plays a crucial role in DTF transfers. These powders should be compatible with the selected films and inks to facilitate a strong adhesion and prevent peeling. Investing time and resources into sourcing high-quality materials pays off in the long run, as it directly influences the aesthetic appeal and durability of your finished products, making it a critical aspect for any DTF printing operation.

Mastering DTF Transfer Tips

When it comes to DTF transfer tips, careful attention to detail can drastically improve your printing outcomes. One of the most valuable tips is to always conduct a test print prior to your full production run. This allows you to identify any potential issues such as color discrepancies or misalignments early on, adjusting your settings accordingly. Additionally, keeping detailed records of successful test prints can serve as a reference for future projects, ensuring consistency in quality across your work.

Another key tip is to ensure that your heat press is appropriately calibrated. The temperature and duration of the heat application are critical factors that influence the success of the transfer. Too little heat can result in an inadequate bond, while excessive heat can damage both the transfer and garment. By monitoring these settings closely and having an understanding of your materials’ specifications, you can execute DTF transfers with higher precision and success.

Optimizing DTF Printing Settings

Optimizing your DTF printing settings is essential for achieving the best possible results. One of the most important settings to adjust is the DPI (dots per inch). Higher DPI settings provide sharper images and finer detail, which can significantly elevate the quality of your prints, especially in intricate designs. However, it’s vital to balance DPI settings with print speed to maintain efficiency without sacrificing quality.

Moreover, understanding the specific requirements of your printer model is crucial. Each printer may have unique temperature and speed parameters that need to be adhered to during the printing process. Failure to comply with these specifications can lead to printing errors such as smudging or incomplete transfers. Therefore, always refer to manufacturer guidelines and adjust your settings accordingly to ensure optimal performance during your DTF printing tasks.

Implementing Best Practices for DTF Printing

Implementing best practices for DTF printing can greatly enhance your workflow efficiency and the quality of your outputs. One fundamental practice includes maintaining a clean workspace and equipment. Regularly cleaning your printer heads and ensuring that the printing area is free from dust and contaminants can prevent printing defects and ensure consistent results. Regular maintenance schedules help keep the machinery in top condition, leading to fewer unexpected downtimes.

Additionally, adopting a systematic approach to production planning can help streamline the entire DTF printing process. This involves organizing materials, prepping designs in advance, and establishing a clear timeline for each project. By doing so, you minimize errors and ensure that each step of the process is executed smoothly, which ultimately leads to better quality prints and satisfied customers.

Effective Quality Control in DTF Printing

Effective quality control is vital for ensuring high standards in DTF printing. Establishing rigorous testing protocols before mass production is crucial. This can involve evaluating color accuracy and print alignment during test runs to catch any discrepancies early on. Quality control measures help ensure that your transfers meet customer expectations and maintain the overall integrity of your brand.

Moreover, consistency is key in implementing quality control. Regularly reviewing and updating your quality checks, as well as tracking the performance of various materials and techniques, can foster continuous improvement. By creating a feedback loop that includes both tests and customer input, printers can refine their processes and produce consistently high-quality DTF transfers that enhance the business reputation.

Frequently Asked Questions

What are the best practices for DTF transfers?

Best practices for DTF transfers include using high-quality materials like transfer films and inks, optimizing your printer settings for DPI and temperature, ensuring proper pre-press preparation of garments, utilizing correct transfer techniques with consistent pressure and timing, and conducting regular testing and quality control.

How does the choice of DTF printing settings impact the final print quality?

Choosing the right DTF printing settings is crucial as it directly affects the print’s detail and vibrancy. Adjusting the DPI for finer details and following manufacturer guidelines for temperature and speed ensures a smooth transfer process and prevents issues like smudging or incomplete prints.

What high-quality DTF materials should I consider for the best results?

For optimal DTF transfers, invest in high-quality transfer films that provide good transparency and thickness, along with compatible inks and adhesive powders. These materials significantly enhance the adhesion and durability of the final prints.

What are some effective DTF transfer tips to ensure successful prints?

Effective DTF transfer tips include cooling the printed film properly before application, pre-pressing garments to eliminate moisture, maintaining consistent pressure during the transfer, and adhering to recommended application times to prevent any damage to the fabric.

What is the importance of proper pre-press preparation in DTF printing?

Proper pre-press preparation is critical in DTF printing as it ensures that garments are free from moisture and wrinkles, providing a smooth surface for the transfer. This step greatly enhances adhesion quality and helps avoid issues like bubbling after the print is applied.

How can I maintain the quality of my DTF printing equipment?

To maintain the quality of your DTF printing equipment, regularly perform maintenance to prevent clogs and misprints. Implement a rigorous quality control process that includes routine checks on settings, materials, and test prints to ensure consistent and reliable results.

| Tip | Description |

|---|---|

| 1. Use High-Quality Materials | Invest in high-quality transfer films, inks, and compatible adhesive powders to achieve vibrant and durable prints. |

| 2. Correct Printer Settings | Optimize printer DPI settings and adhere to manufacturer guidelines for temperature and speed during printing. |

| 3. Proper Pre-Press Preparation | Allow printed films to cool and pre-press garments to remove moisture and wrinkles for better adhesion. |

| 4. Utilize the Right Transfer Techniques | Apply consistent pressure and adhere to recommended heat press times for a successful transfer. |

| 5. Testing and Quality Control | Conduct test prints to check for accuracy and maintain equipment to ensure consistent print quality. |

Summary

DTF transfers have become a crucial element for achieving high-quality prints in the garment decoration industry. To excel in DTF printing, utilizing high-quality materials, optimizing printer settings, and paying attention to pre-press preparation are essential strategies. Proper transfer techniques and conducting thorough testing and quality control are also vital for ensuring that prints remain vibrant and durable over time. By incorporating these practices into your printing workflow, you can create stunning prints that not only meet customer expectations but also showcase your expertise in DTF transfers.