DTF transfers, or Direct to Film transfers, are setting a new standard in the custom apparel industry, captivating both beginners and experienced creators alike. This innovative printing process allows for vivid, intricate designs to be transferred onto various fabrics, making it a top choice for custom apparel production. With DTF printing, users can enjoy the advantages of high durability, reduced setup costs, and the ability to create unique designs even for small batch orders. As the demand for personalized clothing continues to rise, mastering the DTF transfer technique can offer substantial opportunities for those looking to break into the world of garment printing. Join us as we explore the essentials of DTF transfers, and unlock the potential of this game-changing printing method for your creative projects.

Also known as Direct to Film printing, DTF transfers are revolutionizing the approach to fabric printing. This advanced technique empowers creators to transfer vibrant designs onto various textiles with ease, combining quality and efficiency. By utilizing a DTF printer, users can harness the benefits of this printing approach, which includes the use of water-based inks that are both economical and durable. Custom apparel enthusiasts will find that DTF printing facilitates an expansive range of applications, from intricate designs on t-shirts to personalized accessories. As we delve deeper, we will uncover the unique features and advantages of this cutting-edge transfer method.

Understanding DTF Transfers: The Basics

DTF transfers, or Direct to Film transfers, represent a significant advancement in the realm of custom printing. This innovative method allows designers to print their creations onto a special film, which can then be applied to various fabric types using heat and pressure. The result is vivid, high-quality designs that are both durable and versatile. For beginners, understanding DTF transfers is crucial, as they blend the qualities of traditional screen printing and modern digital printing techniques, offering a unique solution for apparel businesses.

When you choose DTF, you’re opting for a printing process that can produce complex graphics with precision. Unlike other methods that may restrict you to specific fabric types, DTF is compatible with a wide range of materials, including cotton, polyester, or mixed fabric types. This flexibility means that custom apparel producers can experiment with different substrates, expanding their product lines and appealing to various customer preferences.

The Step-by-Step DTF Printing Process Explained

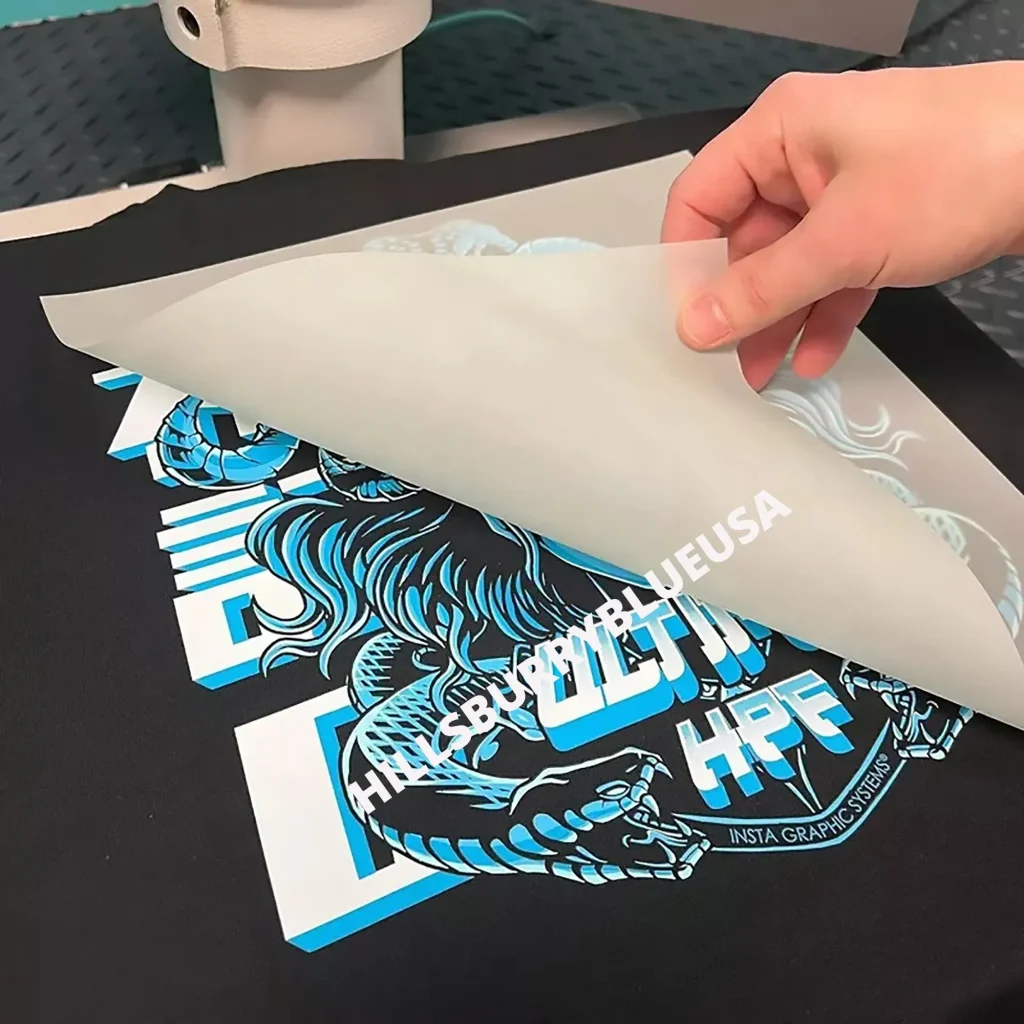

To fully appreciate DTF transfers, one must understand the DTF printing process. This begins with design preparation, where a digital image is crafted using specialized graphic design software. Once the design is complete, it is printed onto a PET film using high-quality DTF inks. This initial step is critical, as it sets the foundation for the entire transfer process, ensuring that the design will remain crisp during application.

Following the printing phase, a heat-activated adhesive powder is sprinkled onto the wet ink, which enhances adhesion to the fabric. The film is then cured with a heat press or conveyor dryer, stabilizing the adhesive. Finally, the film is pressed onto the fabric at specific temperature settings, which varies depending on the material. This meticulous process not only guarantees robust designs but also showcases the potential of DTF transfers in the custom apparel sector.

Exploring the Advantages of DTF Transfers for Custom Apparel

One of the most significant advantages of DTF transfers is their remarkable versatility. Unlike traditional screen printing, which can be limited by the type of fabric used, DTF transfers can be applied to a variety of textiles. This opens the door to endless possibilities for creative expression and product offerings in the custom apparel market, allowing for designs on everything from t-shirts to bags.

Additionally, the durability of DTF transfers is a selling point for businesses. Prints produced through this method are resistant to fading and cracking, maintaining their vibrant colors even after extensive wear and multiple washes. This durability not only satisfies customer expectations for quality but also enhances the lifespan of the garments, making DTF an attractive choice for entrepreneurs looking to build a brand around resilient apparel.

Essential Equipment for Successful DTF Printing

Embarking on your DTF printing journey requires specific equipment to ensure high-quality output. A DTF printer is essential, specifically designed to accommodate the needs of this printing method, or alternatively, an inkjet printer that has been modified for DTF use. The right printer will make a significant difference in the details and vibrancy of your prints.

In addition to a suitable printer, a reliable heat press is necessary for the successful transfer of designs onto apparel. Finding a heat press that allows for adjustable temperature and pressure settings is critical for experimenting with different fabric types, ensuring that each transfer adheres correctly and produces professional results.

Tips for Beginners in the DTF Printing World

Getting started with DTF printing can be overwhelming, but a few key tips can make a significant difference. Firstly, choose high-quality materials, including films and inks, as they directly affect the final print’s vibrancy and longevity. Investing in top-notch supplies ensures that the colors pop and the designs have a resilient finish.

Another crucial tip is to test various heat settings on different fabric types before final production runs. Each material reacts differently to heat, and finding the right combination of temperature and pressing time is key to achieving optimal results in your DTF printing endeavors. This hands-on experience will equip you with valuable insights into the DTF printing process.

The Future Trends in DTF Printing: Growth and Sustainability

The future of DTF printing is poised for considerable growth and innovation, driven by advancements in technology and a growing demand for custom apparel. As more businesses realize the benefits of DTF transfers, including the ability to create customized designs quickly and efficiently, they will likely expand their use of this method. The rise of e-commerce in the clothing industry enhances this trend, making DTF a go-to solution for on-demand printing.

Moreover, as consumers become increasingly eco-conscious, the use of water-based inks in DTF printing aligns with sustainable practices. This not only supports environmentally friendly business models but also attracts a customer base that values responsible production methods. The marriage of quality printing and sustainability will undoubtedly shape the future landscape of custom apparel, making DTF transfers an integral part of this evolving market.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process involves creating a digital design, printing it onto a special PET film using a DTF printer, applying an adhesive powder, curing it, and then transferring it to fabric with heat and pressure. This method combines the best of screen printing and DTG, resulting in vibrant and durable custom apparel.

What are the main advantages of using DTF transfers for custom apparel?

DTF transfers offer several advantages, such as versatility across various fabrics, durability that resists cracking and fading, and cost-effectiveness for small production runs. These benefits make DTF an ideal choice for creating high-quality custom apparel that appeals to a broad audience.

What equipment do I need to get started with DTF transfers?

To start with DTF transfers, you’ll need a DTF printer or a modified inkjet printer, a heat press for transferring designs, high-quality DTF inks and films, and design software like Adobe Illustrator. This essential equipment ensures you can produce vibrant and lasting prints.

How do DTF transfer inks compare to traditional screen printing inks?

DTF transfer inks, which are water-based, offer vibrant colors and excellent durability similar to traditional screen printing inks. However, DTF inks are more versatile in terms of fabric compatibility, allowing for a wider range of materials to be printed on, making them highly suitable for custom apparel.

Can DTF transfers be used on any fabric type?

Yes, one of the key advantages of DTF transfers is their ability to be applied to a wide variety of fabrics, including cotton, polyester, and blends. This compatibility expands the possibilities for custom apparel design compared to other printing methods that may have fabric restrictions.

Why should I choose DTF printing for my custom apparel business?

DTF printing is an excellent choice due to its affordability, versatility, and high-quality results. It allows for smaller production runs, making it ideal for testing new designs without significant financial commitment, while also delivering durable and vibrant prints that satisfy customer demands.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | A printing method that transfers designs onto fabric via heat and pressure, featuring vibrant colors and intricate designs. |

| The DTF Printing Process | 1. Design Preparation 2. Powder Adhesive Application 3. Curing the Adhesive 4. Transfer to Fabric |

| Advantages of DTF Transfers | Versatility, Durability, Cost-Effectiveness |

| Equipment Needed | DTF Printer, Heat Press, DTF Inks and Films, Computer and Design Software |

| Tips for Beginners | 1. Choose Quality Materials 2. Testing Settings 3. Design Optimization 4. Keep Learning |

| Current Trends in DTF Printing | Popularity among small businesses, advancements in ink formulations, eco-friendly practices |

| Future Prospects of DTF Printing | Expansion of application scope, improvements in quality and speed, increased customization opportunities |

Summary

DTF Transfers represent a transformative technique in the realm of custom apparel, allowing creators to print eye-catching designs with remarkable durability. By utilizing a straightforward printing process and high-quality materials, individuals and businesses can harness the benefits of this innovative technology. With the potential for customization and an expanding market demand, DTF Transfers not only offer a valuable tool for artistic expression but also a viable pathway to establishing a successful clothing brand. As you embark on your DTF printing journey, remember to embrace creativity, adaptability, and continuous learning to truly unlock the power of this method.