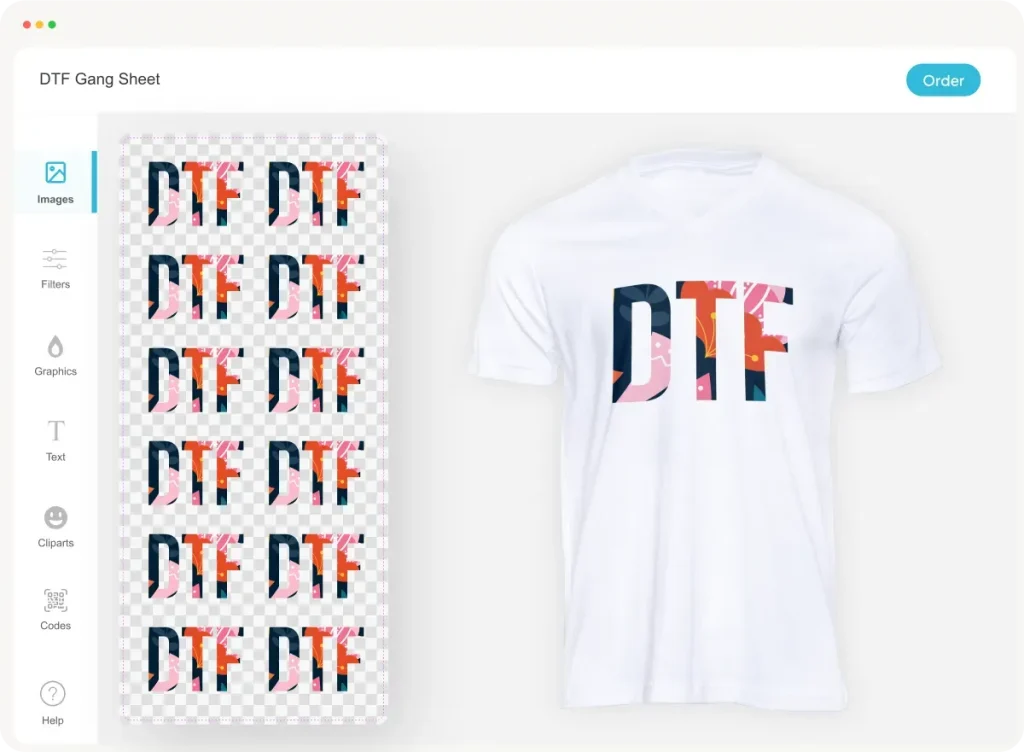

DTF Gangsheet Builders have emerged as essential tools in the world of Direct-to-Film (DTF) printing, transforming how businesses handle textile printing. These innovative builders enable companies to efficiently print vibrant designs on gang sheets, maximizing their production capabilities while minimizing waste. Whether you’re in the custom apparel industry or exploring print-on-demand options, understanding the mechanics of gang sheet printing can significantly streamline your workflow. As the demand for personalized and high-quality prints rises, DTF Gangsheet Builders are perfectly positioned to meet these challenges. In this article, we delve into the benefits of these tools and their impact on enhancing the overall efficiency of your textile printing processes.

The realm of Direct-to-Film printing is evolving with the introduction of gang sheet builders, a term that resonates with efficiency and quality in textile design transfer. By allowing multiple designs to be printed on a single sheet of film, these builders provide a streamlined approach to custom workflow management, particularly beneficial for businesses engaged in on-demand printing. As creators aim for vibrant graphics and intricate details, understanding gang sheet printing techniques becomes crucial. This method not only reduces material costs but also accelerates production without compromising on aesthetic appeal. Join us as we navigate through the world of DTF technology and the pivotal role of gang sheet builders in modern print applications.

The Basics of DTF Printing Technology

Direct-to-Film (DTF) printing represents a significant advancement in the field of textile printing, allowing for a seamless transfer of designs onto fabric with remarkable precision. The DTF printing process involves printing a specialized ink on film, which is then applied to garments via heat transfer. This method not only ensures high-resolution images but also supports a variety of fabric types, making it a versatile choice for custom apparel. As the demand for unique and personalized clothing intensifies, understanding the intricacies of DTF printing prepares businesses to meet customer expectations efficiently.

At its core, DTF printing merges technology and creativity, empowering brands to produce customized items that resonate with consumers. Utilizing vibrant colors and intricate designs, the DTF technique competes favorably against traditional methods like screen printing and direct-to-garment printing. By embracing this technology, businesses can offer a broader range of products while maintaining quality, positioning themselves well within a competitive market.

Advantages of DTF Gangsheet Builders

DTF Gangsheet Builders provide numerous advantages that significantly boost the efficiency of the DTF printing process. By consolidating multiple designs on a single sheet of film, these tools optimize material usage, allowing businesses to lower costs while maximizing output. The increased efficiency translates to quicker turnaround times, essential for meeting tight deadlines and fulfilling customer orders promptly.

Moreover, the cost-effectiveness of using gang sheets makes DTF gangsheet builders an indispensable resource for small and large printing operations alike. With the ability to reduce waste, businesses not only save on ink and material expenses but also contribute to more sustainable practices within the textile industry. By investing in DTF Gangsheet Builders, companies can enhance their operational workflows while aligning with growing consumer demand for eco-friendly production methods.

Best Practices for Leveraging DTF Gangsheet Builders

To optimize the use of DTF Gangsheet Builders, implementing best practices is crucial. First and foremost, design optimization plays a significant role in maximizing output. Utilizing advanced graphic design software enables users to experiment with sizes and arrangements, ensuring that gang sheets are filled efficiently without compromising on the quality of each print. An attentive approach to spacing between designs also minimizes the risk of overlap, which is critical for maintaining the clarity of prints.

Additionally, managing color profiles effectively enhances the final product’s appearance. Businesses should ensure that monitors are properly calibrated to reflect true colors, and it’s essential to use compatible color profiles for inks and films to ensure accuracy during the heat transfer process. Focusing on these elements not only elevates the quality of prints but also reinforces brand reliability in surpassing customer expectations.

Color Management in DTF Printing

Color management is a vital component in the DTF printing workflow, directly affecting the fidelity of designs transferred onto fabrics. By ensuring that color profiles are optimized for the specific type of ink and film used, businesses can achieve more vibrant and accurate representations of their designs. Further, using calibrated monitors helps maintain consistency across various print jobs, leading to a reliably high-quality output that delights customers.

Investing time in learning about color theory and the behavior of different inks can also provide a significant advantage. Understanding how colors translate from a digital screen to fabric helps in selecting the right hues that resonate with the target audience. By mastering color management, printing companies not only improve their product quality but also enhance their overall brand image, encouraging repeat business from satisfied customers.

Emerging Trends in DTF Printing

As the garment industry evolves, emerging trends significantly impact the DTF printing landscape. The increasing demand for on-demand and sustainable printing solutions is reshaping production methods, making DTF a preferred option for many businesses. This shift allows for reduced waste, as items are printed only when needed, aligning closely with eco-friendly practices and consumer preferences for sustainability.

Furthermore, the market is seeing a surge in personalization, with consumers seeking unique garments that reflect their personal style. DTF printing supports this trend by enabling affordable small-batch production without the need for large inventory investments. Small businesses can take advantage of these trends by investing in DTF technology, carving out niche markets, and delivering customized products that foster deeper connections with their clientele.

Recommended Tools for Effective Gangsheet Creation

For businesses leveraging DTF printing, utilizing the right tools is essential for the effective creation of gang sheets. Industry-standard CAD software offers users the flexibility to design intricate layouts and optimize designs for efficient film use. These tools can dramatically simplify the overall workflow from design to print, giving users the ability to focus on creativity while minimizing technical hassles.

Alongside CAD software, specialized DTF software has emerged as a crucial resource for streamlining the gangsheet creation process. These programs often provide predefined templates, aid in design arrangements, and assist with color management, ensuring a smoother transition from digital design to physical product. By integrating such innovative technologies, businesses can enhance their productivity and maintain a competitive edge in the dynamic world of textile printing.

Frequently Asked Questions

What are DTF Gangsheet Builders and how do they work?

DTF Gangsheet Builders are specialized tools designed to optimize the Direct-to-Film (DTF) printing process by arranging multiple designs on a single film sheet. This approach minimizes waste, enhances efficiency, and allows businesses to produce high-quality prints on demand, ideal for custom textile printing.

How can using DTF Gangsheet Builders improve printing efficiency?

By utilizing DTF Gangsheet Builders, businesses can print several designs simultaneously, significantly reducing production time. This optimized workflow not only saves on material costs but also facilitates quicker turnaround on custom orders, leading to higher customer satisfaction.

What benefits do DTF Gangsheet Builders offer for small print runs?

For smaller print runs, DTF Gangsheet Builders maximize material usage by allowing multiple designs to be printed on one sheet. This reduces costs associated with ink and film, making it a cost-effective solution for businesses looking to offer customized products without financial strain.

What are best practices for designing gang sheets with DTF Gangsheet Builders?

Best practices include optimizing design sizes, ensuring proper spacing between designs to avoid overlap, and using graphic design software to maximize layout efficiency. These steps help maintain quality while minimizing waste in the DTF printing process.

How does color management affect the output quality of DTF printing with gang sheets?

Effective color management is crucial for DTF printing success. Users should ensure their monitors are calibrated and apply correct color profiles for their inks and films. This attention to detail guarantees that the vibrant colors in designs are accurately transferred onto fabrics.

What trends are influencing the adoption of DTF Gangsheet Builders in the textile industry?

The rising demand for customized and sustainable apparel is propelling the popularity of DTF printing. DTF Gangsheet Builders facilitate on-demand printing, reducing waste and enabling businesses to cater to niche markets that seek personalized, high-quality textile products.

| Aspect | Details |

|---|---|

| What is DTF Printing? | An advanced method for printing vivid graphics directly onto a special film, later heat transferred onto fabric, ideal for custom apparel. |

| Understanding Gang Sheets | A technique to arrange multiple designs on one sheet, optimizing material usage and cost efficiency, especially for smaller runs. |

| Benefits of DTF Gangsheet Builders | 1. Improved Efficiency 2. Cost Savings 3. Quicker Turnaround |

| Best Practices for DTF Gangsheet Builders | 1. Design Optimization 2. Color Management 3. Material Selection |

| Market Trends Affecting DTF Printing | 1. On-Demand Printing 2. Personalization and Niche Markets |

| Essential Tools and Software | 1. CAD Programs 2. Specialized DTF Software |

Summary

DTF Gangsheet Builders play a crucial role in enhancing the efficiency and quality of fabric printing. As businesses in the garment industry increasingly turn to customization, understanding how to effectively use DTF gangsheet builders can lead to significant improvements in production processes. By optimizing design layouts, managing colors, and selecting the right materials, companies can not only save costs and time but also meet the growing demand for personalized products. This deep dive into DTF gangsheet builders reveals their importance in adapting to market trends and ensuring high-quality outputs, making them indispensable in today’s competitive textile printing landscape.