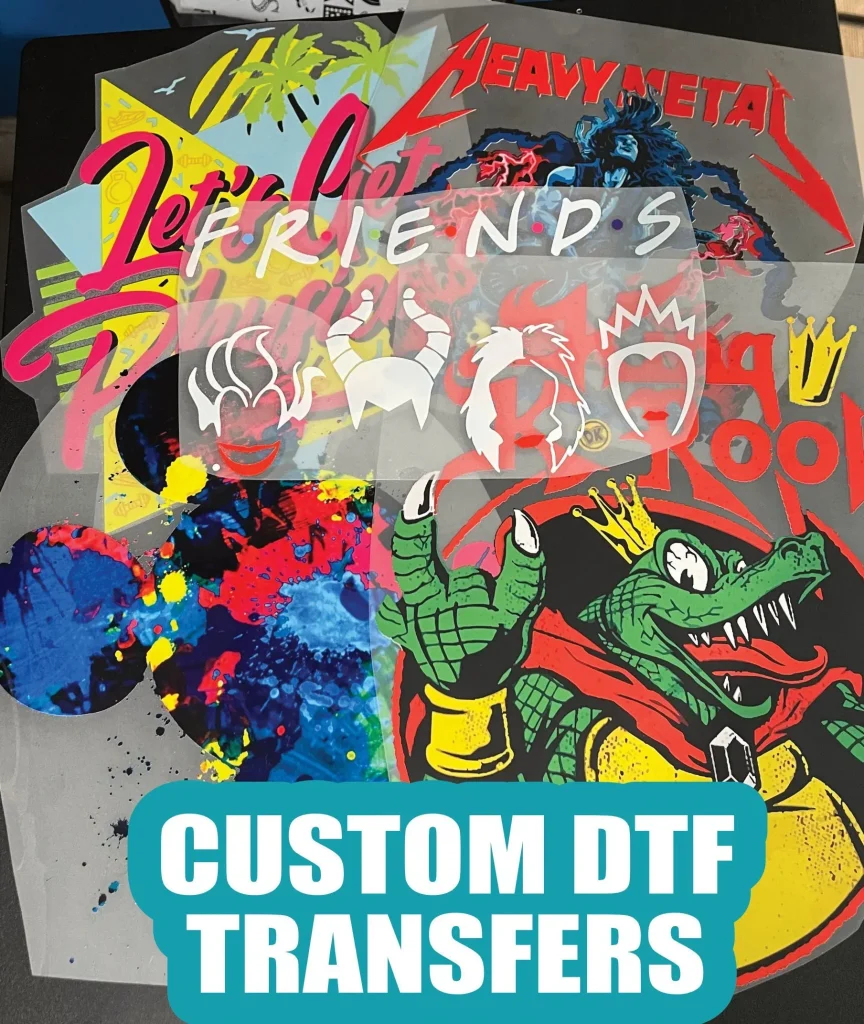

In the dynamic world of textile printing, **DTF transfers** (Direct to Film transfers) have emerged as a cutting-edge technology that redefines quality and accessibility in custom apparel production. This innovative technique allows designers to create vibrant and intricate prints on various fabrics, showcasing the rich colors and fine details that today’s consumers demand. Whether you’re looking to personalize garments for a special occasion or develop a unique line of clothing, DTF printing offers a multitude of advantages that suit any creative vision. As the demand for bespoke items continues to grow, understanding the benefits of fabric printing techniques like DTF becomes increasingly crucial for businesses aiming to stand out in a competitive marketplace. Join us as we explore how DTF transfers not only enhance your printing capabilities but also elevate your brand to new heights.

Direct to Film (DTF) printing, a revolutionary method in the realm of fabric printing, provides businesses with an exciting avenue for creating custom designs with unparalleled efficiency. This process facilitates the transfer of high-resolution images onto textiles, allowing for versatility and creativity in custom apparel. As alternatives to traditional printing methods gain traction, the implications of DTF technology extend far beyond typical garment decoration, positioning it as an essential tool for contemporary fashion and promotional products. Furthermore, DTF’s cost-effective nature makes it particularly appealing for small runs and personalized orders, catering to the growing consumer demand for unique and customized items. By delving into the distinct advantages and applications of DTF transfers, we uncover why this technology is rapidly becoming the go-to solution for both seasoned professionals and emerging designers alike.

Understanding the DTF Printing Process

DTF printing, or Direct to Film printing, revolutionizes how designs are transferred onto fabric. The process begins with printing high-resolution images on a specialized transfer film using eco-solvent or water-based inks. This ink is then treated with an adhesive powder, which allows the vibrant inks to bond effectively when heat is applied. When heat and pressure are applied using a heat press, the printed film adheres securely to the textile material, making the colors come alive and ensuring sharp detail.

Unlike traditional fabric printing methods, DTF transfers can be utilized on various materials, from cotton to polyester blends. This process ensures that the prints remain highly durable, capable of withstanding multiple washes without fading or peeling. As a result, businesses can deliver products that look professional and maintain high quality over time, setting the standard in the competitive world of textile printing.

Key Advantages of DTF Transfers in Textile Printing

The advantages of DTF transfers are multifaceted, making them an appealing choice for custom apparel businesses. One major benefit is the exceptional print quality; DTF technology allows for high-definition images and vibrant colors that stand out against the fabric, often outperforming traditional methods like screen printing. This precision is particularly important for brands that demand impeccable quality on their merchandise, enabling them to forge a stronger connection with their customers.

Another advantage is the cost-effectiveness of DTF printing, especially for short production runs. Small businesses can produce custom apparel in limited quantities without the financial strain typically associated with bulk orders. This flexibility allows for creative experimentation and personalization, making it easier to launch unique products while catering to diverse consumer preferences.

Applications of DTF Transfers in Custom Apparel

DTF transfers are immensely beneficial in the realm of custom apparel, offering endless possibilities for creativity and individual expression. From detailed logos for local businesses to unique designs for events like family reunions, DTF technology provides an efficient method for producing high-quality garments quickly. This functionality appeals particularly to small and start-up brands looking to differentiate themselves and establish their identity in a competitive market.

Moreover, DTF transfers allow for personalization at scale, enabling companies to offer customized items tailored to individual customer preferences. This capability not only enhances customer satisfaction but also encourages brand loyalty, as consumers are often drawn to the unique and authentic products that reflect their personal style.

Cost-Effectiveness of DTF Transfers

One of the standout features of DTF transfers is their remarkable cost-effectiveness, particularly for small to medium-sized businesses. Unlike screen printing, which often requires expensive set-up costs based on the number of colors, DTF printing simplifies this approach by enabling a single film to produce multi-colored designs without incurring significant additional costs. This allows entrepreneurs to manage their budgets efficiently while still maintaining a professional product.

For businesses focused on sustainability and resource management, DTF printing also minimizes waste, as it can be used for on-demand production. This reduces the need for excess inventory and helps businesses respond swiftly to market trends, thereby aligning financial savings with modern consumer demands for innovation and customization.

Durability and Longevity of DTF Printed Products

Durability is a crucial factor that adds value to products featuring DTF transfers. The advanced adhesives and high-quality inks used in the DTF printing process result in prints that can endure repeated washing and heavy wear, making them an excellent choice for everyday apparel. Customers can trust that their garments will retain their vibrant colors and intricate details over time, resulting in enhanced satisfaction and repeat purchases.

This durability also translates to higher customer retention rates, as consumers are likely to return to brands that offer lasting quality. In a market filled with fast fashion options, brands employing DTF technology set themselves apart by providing long-lasting products that consumers can feel good about investing in.

The Future of DTF Transfers in the Textile Industry

The potential of DTF transfers is expansive as advancements in textile printing continue to evolve. With increasing demand for custom and high-quality printing solutions, DTF technology is positioned to play a significant role in future innovations. Researchers and industry leaders are looking into refining printing techniques, improving ink quality, and reducing production costs further, which will likely propel DTF into broader applications including home decor and specialized promotional items.

Moreover, the rise of e-commerce and personalization trends creates a fertile landscape for DTF printing technology. As consumers increasingly seek unique, customized products, brands can leverage this printing method to cater directly to individual customer preferences efficiently and cost-effectively. The future of DTF transfers appears bright, promising considerable opportunities for growth and expansion in the textile printing sector.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs onto a specialized film that is then transferred onto fabrics using heat and pressure. This technique allows for vibrant colors and intricate designs to be applied to various textiles, making it a preferred choice for custom apparel and fabric printing.

What are the top benefits of using DTF printing for custom apparel?

The primary benefits of using DTF printing for custom apparel include high-quality prints with vibrant details, cost-effectiveness for small runs, versatility across different fabric types, ease of use for businesses, and durability that withstands multiple washes without fading.

Can DTF transfers be applied to any type of fabric?

Yes, DTF transfers can be applied to a variety of fabrics, including cotton, polyester, and their blends. This versatility makes DTF printing an excellent choice for a wide range of clothing items, from t-shirts to specialized sportswear.

How does DTF printing compare to traditional textile printing methods?

DTF printing offers several advantages over traditional textile printing methods such as screen printing. It allows for high-quality, detailed designs, supports quick turnarounds for small runs, and is suitable for numerous fabric types, making it more adaptable for custom products.

How durable are designs created with DTF transfers?

Designs printed using DTF transfers are highly durable and can withstand multiple washes without significant fading or peeling. This longevity ensures that garments maintain their vibrant colors and detailed designs over time, appealing to customers seeking quality in custom apparel.

What are some common applications for DTF printing besides custom apparel?

In addition to custom apparel, DTF printing is widely used for promotional products. Companies utilize DTF transfers for branding merchandise such as corporate gifts, event giveaways, and trade show items, benefiting from the cost-effective production of small runs.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs on a specialized film for application on textiles using heat and pressure. |

| Benefits of DTF Transfers | 1. High-quality prints with intricate details and vibrant colors. 2. Cost-effective for small production runs, ideal for customization. 3. Versatile applications suitable for various fabric types. 4. Seamless integration into existing printing workflows. 5. Durable prints that withstand multiple washes. |

| Applications of DTF Transfers | 1. Custom Apparel – Personalized clothing and branded merchandise. 2. Promotional Products – Effective branding for corporate gifts and events. 3. Fashion Industry – Unique designs and innovative fashion statements. |

| Future Outlook of DTF Transfers | Promising growth driven by demand for customizable solutions, with potential expansions into various fields beyond textiles. |

Summary

DTF transfers are revolutionizing the textile printing industry by combining versatility with high-quality results. This method allows for intricate designs to be printed onto fabrics in a cost-effective manner, making it ideal for custom apparel and promotional products. With a durable finish that withstands the test of time, DTF transfers are proving to be a staple for designers and businesses alike. As the industry continues to innovate, embracing DTF transfers may provide significant competitive advantages and opportunities for growth in the market.