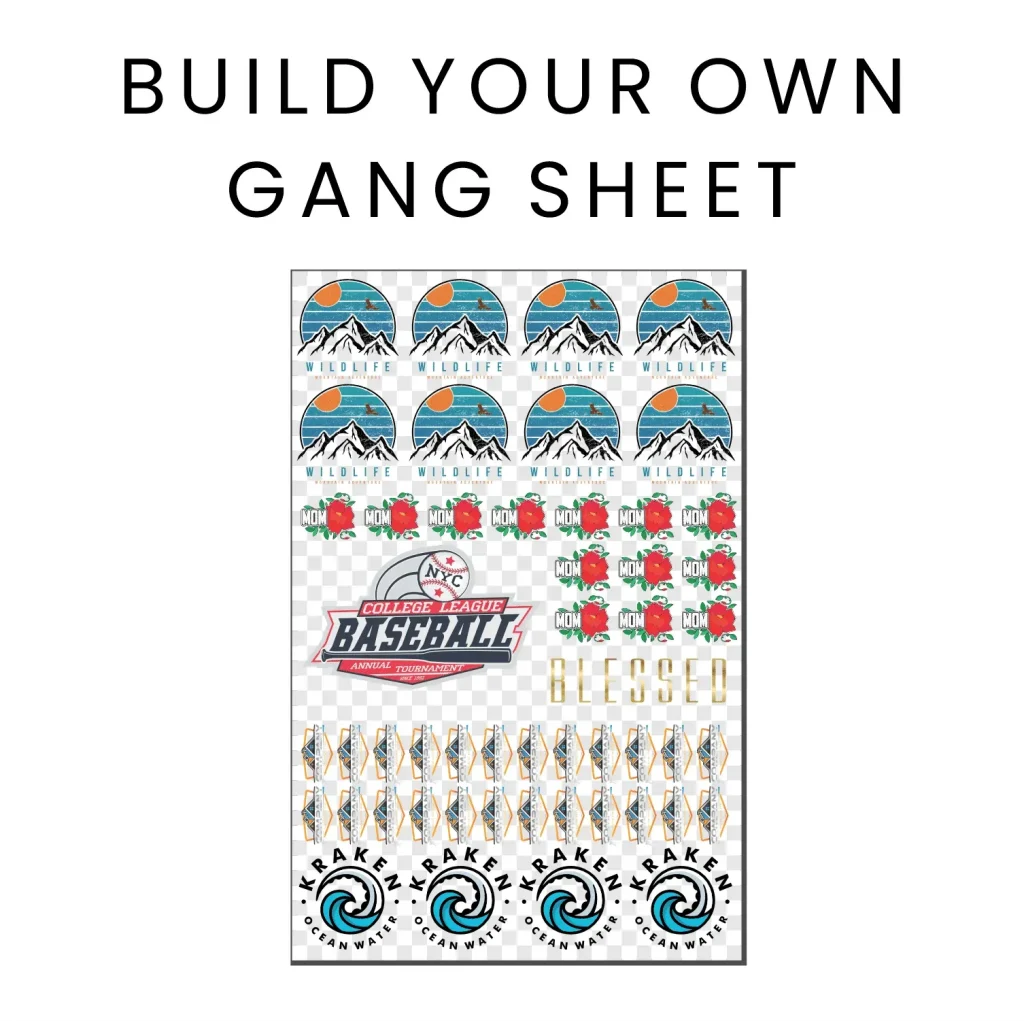

In the competitive landscape of printing, having the right tools can drastically change your operational success. Enter the **DTF Gangsheet Builder**, an innovative solution designed to streamline the printing process and enhance productivity. By optimizing your print workflow automation, this tool maximizes efficiency in printing, allowing businesses to reduce waste and save time. With DTF printing technology at the forefront, the Gangsheet Builder facilitates custom transfer printing that promotes vibrant and high-quality output. Today, we will delve into the benefits of implementing the DTF Gangsheet Builder, showcasing how it can revolutionize your printing business efficiency.

The advent of advanced solutions like the **Smart Gangsheet Builder** is transforming the way printing businesses function. Known for maximizing print workflow and minimizing material waste, this tool is essential for those involved in custom print jobs. As the printing sector embraces new technologies, these systems not only enhance production speed but also improve output quality and consistency. With the increasing need for automation in printing operations, alternatives such as custom transfer platforms are becoming pivotal in meeting client demands efficiently. In this discussion, we will uncover the potential benefits and applications of these innovative tools tailored for today’s print industry.

Maximizing Workflow Efficiency with DTF Printing Technology

Maximizing workflow efficiency in printing is crucial for businesses aiming to meet increasing demands while maintaining high-quality output. DTF printing technology stands at the forefront of this transformation, offering remarkable advantages such as speed and versatility. With the ability to print on a wide range of fabrics and materials, DTF printers enable businesses to streamline their operations, allowing them to produce a diverse array of products—from custom apparel to promotional shares—without compromising production speed.

Additionally, employing DTF technology not only enhances your print quality but also reduces lead times significantly. By facilitating rapid prototyping and small batch productions, printing businesses can respond more quickly to customer requests and market trends. As companies incorporate DTF technology into their workflows, they see profound shifts in productivity, enabling them to optimize their resources and enhance overall business efficiency.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it improve print workflow automation?

The DTF Gangsheet Builder is a tool that automates the nesting of designs on gang sheets for DTF printing, maximizing space usage and reducing waste. By streamlining the layout process, it enhances print workflow automation, allowing businesses to produce multiple custom transfers efficiently.

How does the DTF Gangsheet Builder contribute to maximizing efficiency in printing businesses?

The DTF Gangsheet Builder significantly maximizes efficiency by optimizing space on film sheets, which reduces material costs and speeds up production times. This allows printing businesses to handle more jobs while maintaining high-quality output, driving profitability.

What are the benefits of DTF printing technology in conjunction with the DTF Gangsheet Builder?

DTF printing technology, when used with the DTF Gangsheet Builder, offers vibrant colors and durability, alongside streamlined processes. This combination facilitates custom transfer printing with lesser material waste and quicker turnaround times, enhancing overall printing business efficiency.

Can the DTF Gangsheet Builder enhance quality control in a printing operation?

Yes, the DTF Gangsheet Builder enhances quality control by ensuring accurate alignment and sizing of designs. Its built-in checks minimize reprints due to errors, which conserves resources and improves customer satisfaction.

How is the DTF Gangsheet Builder affecting the growth of custom transfer printing in the market?

The DTF Gangsheet Builder is pivotal in the growth of custom transfer printing by allowing crafters to optimize intricate designs efficiently. This innovation is propelling the DTF printing technology forward, making it a sought-after method in the printing industry.

What steps should a business take to integrate the DTF Gangsheet Builder into its operations?

To integrate the DTF Gangsheet Builder, businesses should first assess their workflow to identify inefficiencies. Ensure compatibility with printing equipment, train staff on effective usage, and continuously monitor performance to optimize the integration.

| Key Point | Details |

|---|---|

| Maximizing Efficiency | The DTF Gangsheet Builder streamlines the printing process, reduces waste, and improves productivity. |

| Understanding DTF Printing | DTF printing allows for high-quality output across various materials with vibrant colors and durability. |

| Automation Benefits | The Gangsheet Builder automates design nesting for efficient space utilization, minimizing costs and speeding up production. |

| Quality Control Enhancements | Built-in quality checks ensure designs are correctly aligned, reducing errors and improving customer satisfaction. |

| Recent Developments | Growth in DTF printing technology and market insights guide businesses in making strategic technology investments. |

Summary

The DTF Gangsheet Builder is a vital asset for printing businesses aiming to enhance operational efficiency. It offers innovative solutions that minimize waste, optimize workflows, and improve overall productivity in the competitive landscape of printing. By embracing this tool, businesses can elevate the quality of their custom print services while also reaping significant cost savings. The advancements in DTF technology further support businesses in meeting customer demands with speed and accuracy, making the DTF Gangsheet Builder indispensable for those looking to thrive in today’s fast-paced market.