In the world of custom apparel and textile printing, DTF Transfers are quickly becoming the go-to choice for individuals and businesses alike. Direct-to-Film (DTF) printing stands out with its ability to create vibrant prints that truly capture intricate designs and colors. This state-of-the-art technology not only ensures durability in fabric printing, but also offers remarkable versatility across various materials. As more creators and entrepreneurs embrace the DTF printing advantages, they unlock new possibilities for unique, high-quality products that stand the test of time. In this article, we will explore the ins and outs of DTF transfers, including their efficiency, sustainability, and the latest trends shaping the future of the industry.

Direct-to-Film printing, often abbreviated as DTF, has emerged as a transformative solution in the realm of textile printing. This innovative technique allows for the seamless transfer of detailed designs onto fabrics, resulting in stunningly vibrant prints that appeal to a wide range of consumers. As businesses look for durable fabric printing methods, many are turning to this advanced printing process, which boasts numerous advantages including cost-effectiveness and the capacity for customization. Additionally, the focus on sustainable printing practices aligns with the growing demand for environmentally responsible solutions in the marketplace. By understanding these complementary terms and concepts, stakeholders can fully appreciate the benefits that DTF transfers bring to modern printing.

Exploring the Benefits of Direct-to-Film Transfers

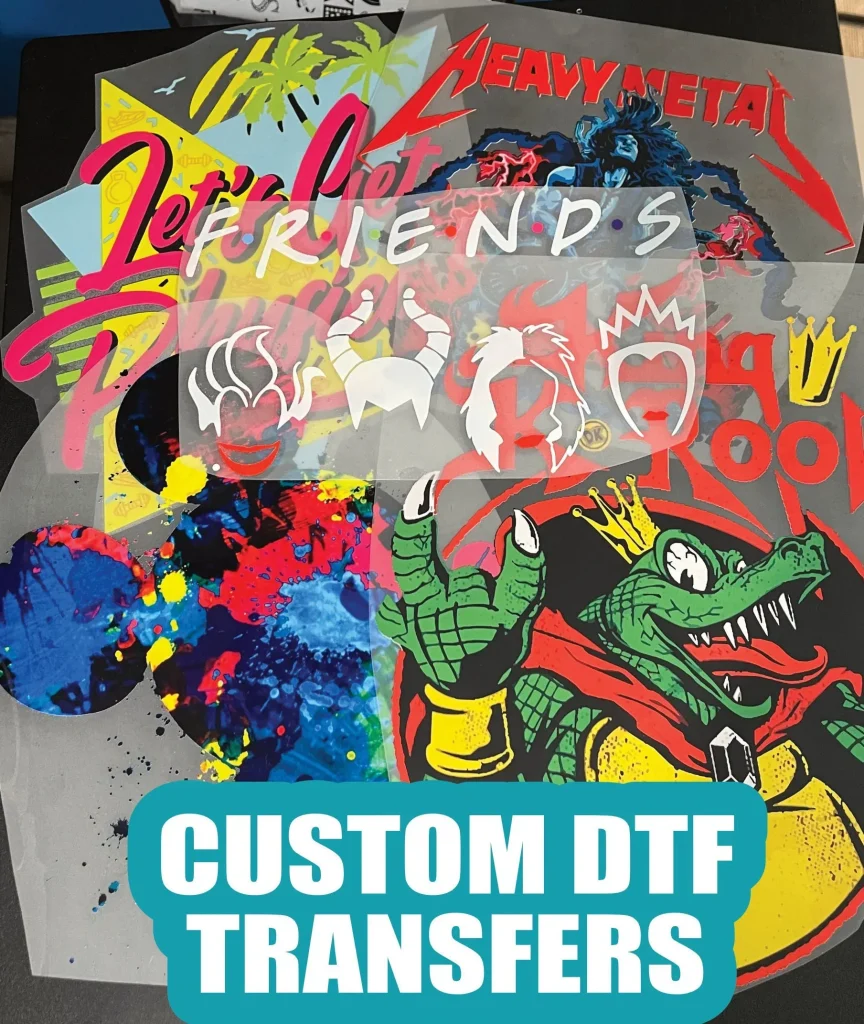

Direct-to-Film (DTF) transfers offer numerous benefits that make them an ideal choice for both creators and businesses in the textile printing industry. One of the most significant advantages is the vibrancy of the prints, which allows intricate and colorful designs to come to life on fabric. Unlike traditional methods, DTF printing achieves high-definition results, making graphics pop with stunning clarity. This technology excels in producing sharp details and an extensive color palette, giving artists the freedom to create bold artistic expressions that capture consumer attention.

Moreover, the durability of DTF prints sets them apart from other printing options. DTF transfers can withstand multiple washes and regular wear without cracking or fading, ensuring that the designs remain vibrant and intact over time. This longevity is particularly appealing to businesses seeking to provide high-quality products that stand the test of time, as it reduces the likelihood of returns or customer dissatisfaction. In a market where quality is paramount, the durability of DTF transfers positions them as a reliable choice for custom apparel.

The Mechanics of DTF Printing Technology

Understanding the technology behind Direct-to-Film (DTF) printing reveals how it achieves its impressive results. DTF printing utilizes a specialized inkjet printing method that allows images to be printed onto a unique transfer film. This film is then coated with a heat-activated adhesive, creating a bond when applied to various fabrics. The use of water-based inks within this process not only enhances the quality of the prints but also aligns with sustainable printing practices, as these inks tend to be more environmentally friendly compared to solvent-based alternatives.

The flexibility of DTF technology is also noteworthy, as it can adapt to a range of fabric types, from cotton to polyester blends. This versatility opens up new avenues for businesses looking to diversify their product offerings. Whether producing sports apparel, fashion items, or promotional merchandise, DTF offers a solution that caters to multiple markets without sacrificing quality. This capability enables businesses to tap into different segments with ease and efficiency.

Durability Factors in DTF Printing

Durability is a defining characteristic of DTF transfers, making them a popular choice for custom designs that will endure the test of time. Unlike traditional screen-printed items that risk cracking or fading, DTF prints can last through countless washes while maintaining their vibrant appearance. This resistance to wear is largely due to the way DTF technology binds the ink directly to the fabric fibers, creating a strong, lasting connection that prevents peeling or deterioration.

Furthermore, the adhesion process used in DTF printing helps to fortify the designs against various environmental factors, such as UV exposure and abrasion. This reliable performance not only enhances the lifespan of the printed materials but also boosts customer satisfaction, as consumers are likely to appreciate garments that remain visually appealing longer. As the demand for high-quality, durable apparel grows, DTF printing stands out as a leading option for businesses committed to delivering exceptional products.

Eco-Friendly Aspects of DTF Printing

As the fashion industry increasingly shifts toward sustainability, DTF printing is leading the charge with eco-friendly practices. Many manufacturers are prioritizing the use of water-based inks, which significantly reduce harmful emissions compared to traditional solvent-based inks. This shift not only minimizes environmental impact but also aligns with consumer values—many shoppers today actively seek out brands that demonstrate a commitment to sustainable practices.

In addition to the inks used, the DTF printing process itself can embrace sustainability. The efficiency of DTF production means less waste overall, as this method allows for short-run orders that do not compromise quality. By reducing material waste and producing items on-demand, businesses can lower their carbon footprint while still meeting customer demands for customization. This commitment to sustainability can enhance brand reputation and attract conscientious consumers.

Cost-Effectiveness of DTF Transfers for Businesses

The cost-effectiveness of Direct-to-Film (DTF) printing makes it an attractive option for businesses, particularly those operating on a smaller scale. Compared to traditional screen printing, DTF requires significantly less initial investment while still offering high-quality prints. Startups can effectively produce limited runs without incurring the high setup costs typically associated with other printing methods, allowing them to remain competitive in an increasingly crowded market.

This financial accessibility does not come at the expense of print quality or vibrancy. DTF transfers maintain impressive color accuracy and strong adhesion, ensuring that businesses can deliver products that meet customer expectations. Coupled with the reduced material waste of the DTF process, businesses stand to increase their profit margins while offering unique, custom apparel at reasonable prices. For entrepreneurs, this balance of quality and cost is crucial for sustainability and growth in the market.

Future Trends in DTF Printing Technology

As the demand for custom products continues to rise, the future of DTF printing technology appears bright. Innovations in the manufacturing of DTF printers and inks are expected to enhance print quality even further, making it easier for businesses to deliver exceptional designs. Future advancements may also include quicker drying times and improved adhesion qualities that increase the efficiency of the printing process. These enhancements will likely attract more businesses to adopt DTF technology, expanding its footprint in the textile industry.

Additionally, as consumer awareness of sustainability grows, DTF printing is likely to evolve to incorporate even more eco-friendly practices. This includes the potential development of biodegradable transfer films and further advancements in ink technology to ensure that the entire printing process remains environmentally responsible. By embracing these trends, businesses utilizing DTF printing can stay ahead of the curve, responding to consumer needs and preferences for sustainable and high-quality custom apparel.

Frequently Asked Questions

What are the benefits of DTF Transfers for vibrant prints?

DTF Transfers, or Direct-to-Film printing, are celebrated for their ability to produce vibrant prints. This technology utilizes specialized inks and transfer films, allowing for bright colors and intricate details to stand out. As a result, designers can create visually appealing designs that attract attention and maintain their quality over time.

How does DTF Printing compare to traditional methods in durable fabric printing?

DTF Printing excels in durable fabric printing compared to traditional methods like screen printing and direct-to-garment (DTG). The DTF process ensures better resistance to fading, cracking, and peeling, even after multiple washes. This durability assures businesses and customers that their prints will remain vibrant and intact, making DTF a superior choice for long-lasting designs.

What are the cost advantages of using DTF Transfers for small businesses?

For small businesses, DTF Transfers present significant cost advantages. The initial investment for DTF printing equipment is lower compared to traditional screen printing setups, which require extensive materials and labor. Additionally, DTF allows for on-demand production of small runs without high costs, making it an economical choice for businesses looking to offer customized products.

Are DTF Transfers environmentally friendly compared to other printing methods?

Yes, DTF Transfers can be more environmentally friendly than traditional printing methods. Many manufacturers are adopting sustainable printing practices by using eco-friendly inks and materials in the DTF process. This shift aligns with the growing consumer demand for sustainability, enhancing a brand’s reputation and resonance with environmentally conscious customers.

How does the technology behind DTF Printing work?

The technology behind DTF Printing combines high-resolution inkjet printing and innovative heat transfer techniques. The process involves printing designs on a special transfer film with water-based inks, then applying an adhesive powder and curing it with heat. The final transfer is achieved by applying heat again, ensuring a strong bond between the design and fabric, which enables vibrant color reproduction across various material types.

Can DTF Transfers be integrated into existing printing workflows easily?

Yes, DTF Transfers can be seamlessly integrated into existing printing workflows. Businesses already using other printing methods can transition to DTF without significant disruptions, thanks to its adaptable nature. This integration enables companies to expand their service offerings and meet the demand for custom and high-quality prints efficiently.

| Key Points | Description |

|---|---|

| What is DTF Printing? | A method of printing designs on transfer film using water-based inks that are heat transferred onto fabrics. |

| The Technology Behind DTF Transfers | Utilizes inkjet technology and special film, allowing for vibrant colors and versatility across fabric types. |

| Advantages of DTF Transfers | Includes vibrancy, durability, and cost-effectiveness compared to traditional methods. |

| Market Trends | The growing popularity among small businesses and increased focus on sustainability practices. |

| Essential Equipment | Requires a DTF printer, heat press, and specific transfer films and inks. |

| Integration into Existing Workflows | Easily integrates with other printing methods, making it accessible for various businesses. |

Summary

DTF Transfers are setting a new standard in custom textile printing, delivering vibrant colors that stand the test of time. This innovative method allows designers and businesses to breathe life into their unique designs while ensuring durability and cost-effectiveness. As the demand for personalized apparel continues to grow, understanding the ins and outs of DTF Transfers can give businesses a competitive edge. The seamless integration into existing workflows makes DTF an attractive option for all print shops, empowering them to offer high-quality products that meet consumer expectations for style and sustainability. By adopting DTF printing, companies can position themselves at the forefront of a thriving industry poised for further expansion.