In the ever-evolving world of custom garment printing, DTF Transfers have emerged as a game-changer for both businesses and consumers. Short for Direct-to-Film printing, this innovative technology offers a vibrant and high-resolution output that sets it apart from traditional methods like screen printing and DTG (Direct-to-Garment) processes. By printing designs onto a specially coated film before transferring them onto various fabrics, DTF delivers impressive versatility and quality. This method not only ensures durability against common issues like fading and cracking but also presents a cost-effective printing solution ideal for both small and large runs. As we explore the advantages of DTF Transfers in detail, you’ll discover why this modern printing approach is rapidly gaining popularity in the textile industry.

When exploring custom apparel techniques, the term DTF Printing refers to a method that utilizes film for transferring designs onto garments. Known for its efficiency and ability to produce detailed prints, this process is quickly becoming a favored alternative to traditional printing strategies such as screen printing and DTG. The flexibility DTF offers — allowing printing on a wide array of fabric types — sets it apart from its competitors. With each method possessing unique attributes, understanding the nuances of DTF and how it compares to other printing methods is essential for anyone looking to leverage the best printing solutions for their projects. This discussion will unveil the significant benefits of DTF Transfers and how they effectively meet modern custom printing demands.

Understanding DTF Printing Technology

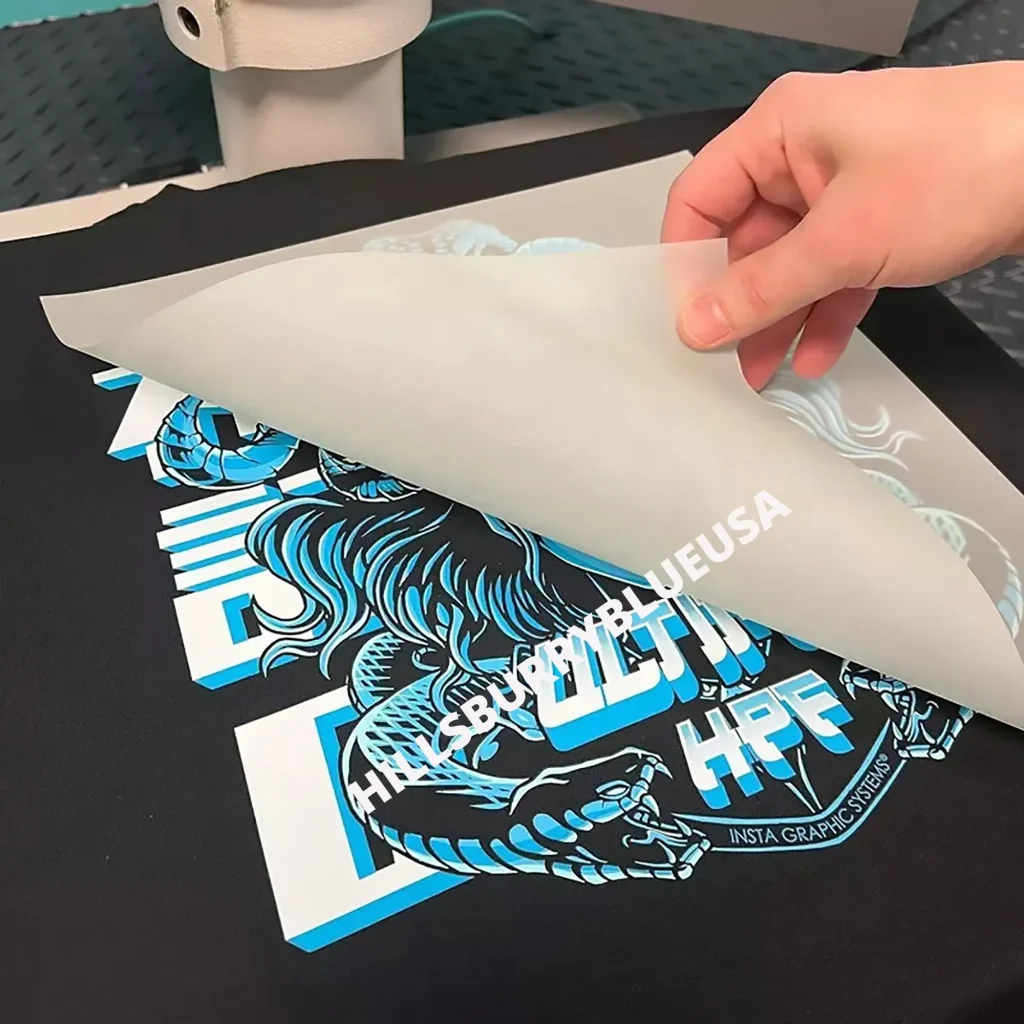

Direct-to-Film (DTF) printing is a cutting-edge technology that has transformed the custom garment printing landscape. By utilizing a specialized film that is printed with vibrant ink and then heat-pressed onto fabric, DTF achieves results that are both striking and durable. This method is favored for its flexibility, enabling a wide variety of materials—from 100% cotton to polyester blends—to be used without compromising quality. The process not only enhances the aesthetic appeal of garments but also allows for intricate designs that capture attention.

Moreover, the DTF technology addresses some of the limitations found in traditional printing methods. Unlike Direct-to-Garment (DTG) printing, which primarily works best with cotton fabrics, DTF allows businesses to explore a range of fabric options. This capability underlines the versatility of DTF printing, making it an exemplary choice for diverse fashion and apparel projects that require different materials, without the need for multiple printing systems.

The Advantages of DTF Transfers in Custom Printing

DTF transfers are increasingly becoming a preferred choice due to their numerous advantages. One of the standout features of DTF printing is its ability to produce high-quality, eye-catching prints that can endure the test of time. The prints are resistant to cracking and fading, which is particularly important for businesses that prioritize longevity in their products. For custom designs that are meant to be worn regularly, such durability ensures that customers remain satisfied long after their purchase.

Additionally, DTF transfers are highly adaptable to various printing needs. Whether for small batch orders or larger production runs, DTF can efficiently handle different scales without significant changes in cost or quality. This capability is particularly beneficial for businesses exploring unique or limited-edition designs, allowing them to cater to niche audiences without breaking the bank.

Comparing DTF vs DTG Printing

When comparing DTF and DTG printing, the differences in material compatibility and production capabilities become clear. DTG printing excels in delivering stunning detail and color accuracy on cotton fabrics, making it an ideal choice for intricate designs. However, its reliance on cotton limits its applicability across various fabric types. In contrast, DTF offers unmatched versatility, allowing designs to be printed on a far broader range of materials, including synthetic blends. This flexibility makes DTF more appealing to businesses that work with different fabric options and want to diversify their product offerings.

Moreover, the setup process for DTF is usually more straightforward compared to DTG. With DTF, there are fewer limitations regarding fabric types, which translates into less downtime and higher efficiency for print providers. This difference not only enhances productivity but also offers a more responsive approach to market demand, enabling businesses to deliver promptly to customer needs.

Evaluating DTF vs Screen Printing for Quality and Costs

Screen printing has long been the go-to method for bulk printing due to its cost-effectiveness at high volumes. However, it requires an extensive setup process that can deter small to medium runs. When looking at smaller orders, DTF transfers shine brighter, as they allow for high-quality prints without the need for large-scale production runs. This quality-tailored approach means companies can reduce waste and maintain flexibility in their offerings.

In terms of print quality, DTF transfers can achieve intricate designs with vivid color prints comparable to, if not surpassing, traditional screen printing. This capability is particularly advantageous for businesses looking to merge high-quality visuals with cost-effective production. As such, DTF becomes the ideal choice for custom designs that demand both detail and durability in smaller quantities.

Speed and Efficiency of DTF Transfers

In the fast-paced world of custom printing, speed is a crucial factor that often directs business choices. DTF transfers offer rapid production times compared to other methods, particularly in contrast to screen printing, which typically requires longer setup times and multiple steps to achieve a finished product. This efficiency makes DTF a compelling option for businesses needing quick turnarounds on orders, especially in on-demand printing scenarios.

Additionally, the ability to quickly shift between designs with DTF technology minimizes production bottlenecks. When a company operates on a tight schedule and requires flexibility, DTF printing allows for quick adaptations without sacrificing quality, making it a favored approach among businesses looking to scale rapidly in a competitive market.

Making an Informed Decision: Which Printing Method to Choose?

Selecting the most suitable printing method involves assessing specific project needs, including order size, design complexity, and fabric characteristics. For small orders, DTF printing is often recommended due to its cost efficiency and adaptability to various materials. It empowers even small businesses to offer customized solutions without incurring the high costs associated with other traditional methods.

For those needing to produce complex designs on cotton or a special project with detailed motifs, DTG might be the best fit. On the other hand, established brands looking at mass production may still find screen printing the most economical choice despite the initial setup costs. Understanding the strengths and weaknesses of each method is vital for making successful printing decisions in today’s dynamic market.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a modern printing technique that involves printing designs onto a specialized film, which is then heat-pressed onto various fabric types. This method allows for vibrant, high-resolution prints that maintain quality and durability, making DTF an excellent choice for custom garment printing.

How does DTF printing compare to DTG printing?

When comparing DTF vs DTG printing, DTF stands out for its versatility, as it can be used on a wider range of materials, including polyester and blends. While DTG printing excels in quality for detailed designs on cotton fabrics, DTF transfers excel in their ability to produce vibrant colors and fine details across multiple fabric types.

Is DTF transfer printing a cost-effective printing method?

Yes, DTF transfer printing is considered a cost-effective printing method, especially for small orders. Unlike DTG printing, which may have high setup costs, DTF can handle both small and large runs efficiently, making it an attractive option for businesses looking to provide custom designs without high entry costs.

What are the advantages of DTF transfers over screen printing?

DTF transfers offer several advantages over screen printing, particularly in terms of detail and versatility. While screen printing is efficient for large batches, DTF provides high-quality prints with intricate detail and can accommodate a wider range of fabrics, making it ideal for smaller custom orders.

How durable are prints made with DTF transfers?

DTF transfers are highly durable, resisting cracking, fading, and peeling, which are common issues with traditional printing methods. This durability makes DTF printing a preferred choice for customers looking for long-lasting and high-quality printed garments.

What types of fabrics can be used with DTF printing?

DTF printing is versatile and can be applied to various fabrics, including cotton, polyester, and fabric blends. This flexibility allows businesses to target a broader market and cater to diverse customer needs when producing custom apparel.

| Aspect | Direct-to-Film (DTF) Printing | Direct-to-Garment (DTG) Printing | Screen Printing |

|---|---|---|---|

| Quality and Durability | High-resolution prints, vibrant colors, exceptional durability against cracking and fading. | Great quality but best with cotton; less durable when compared to DTF. | Good quality for large runs, but lacks detail and durability compared to DTF. |

| Cost-Effectiveness | Cost-effective for both small and large orders, low overhead. | High setup costs; best suited for large production runs. | Cost-effective for mass production, but not for small batches due to initial investment. |

| Speed and Efficiency | Quick turnaround time, ideal for on-demand printing. | Moderate speed; not as fast as DTF, especially for small orders. | Labor-intensive, slower process for small runs. |

| Material Flexibility | Can print on various materials, including polyester and cotton. | Mostly limited to cotton fabrics. | Best for large runs; not suitable for varied fabric types. |

Summary

DTF Transfers are revolutionizing the custom garment printing industry by offering vibrant prints and unparalleled flexibility. This method allows businesses to efficiently produce high-quality designs on a range of materials, making it a viable option for small orders and quick turnarounds. Unlike DTG and screen printing, DTF transfers combine quality, durability, and cost-effectiveness, enabling companies to meet diverse customer demands while keeping production costs low. By staying informed on the advantages of DTF printing, businesses can harness its potential to enhance their product offerings and customer satisfaction.