DTF transfers, or Direct to Film transfers, represent a groundbreaking technique in the world of custom apparel printing. This innovative DTF printing technology not only offers vibrant colors and intricate details but also caters to various fabric types, setting a new standard in personalization. As the demand for high-quality custom apparel continues to rise, the advantages of DTF transfers are becoming increasingly evident, particularly among startups and small businesses looking for cost-effective solutions. In this introductory guide, we will explore the DTF transfer process, highlighting its benefits over traditional printing methods and the latest advancements in the industry. Discover how DTF transfers are transforming the way we approach customizations in fashion.

In the realm of custom garment creation, Direct to Film (DTF) printing has become synonymous with precision and quality, revolutionizing the traditional methods previously relied upon. This approach to printing on special transfer films allows for high-resolution designs, ensuring that every intricate detail is faithfully reproduced on various fabrics. As businesses adapt to the growing trend for personalized merchandise, the DTF transfer advantages—ranging from versatile fabric applications to a streamlined production process—make it an attractive option for creators and retailers alike. By using advanced printing technologies, this method enhances the market’s ability to meet consumer demands with speed and reliability. Join us as we dive deeper into the mechanics and benefits of this innovative custom apparel solution.

Understanding DTF Transfers and Their Process

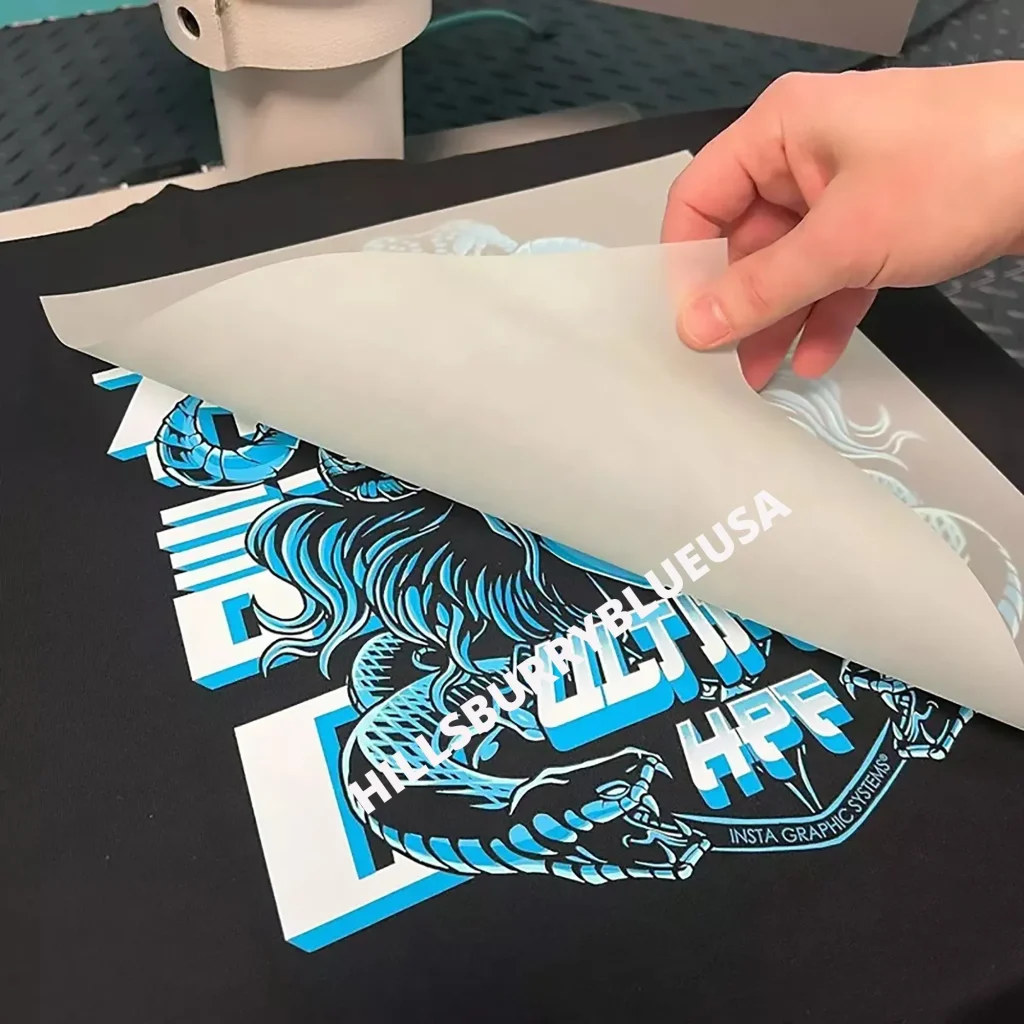

DTF transfers, or Direct to Film transfers, represent a groundbreaking evolution in the realm of custom apparel printing. This innovative technique bypasses traditional methods, facilitating the transfer of intricate, high-resolution designs onto garments through a heat application process. The process begins with creating a digital design tailored for the garment, followed by printing it onto a specialized film. The unique features of DTF printing offer unparalleled levels of color vibrancy and detail, making it a preferred choice for garment decorators aiming for visual impact.

Once the design is printed on the film using specially formulated DTF inks, an adhesive powder is applied to the wet ink. This mixture is then heat pressed onto the fabric, which firmly binds the design to the garment and ensures it withstands the rigors of wear and washing. This method eliminates the need for weeding, significantly reducing the time and labor involved in preparation. The DTF transfer process is not only efficient but also delivers results that appeal to both consumers and manufacturers.

Benefits of DTF Transfers Over Traditional Methods

One of the most notable advantages of DTF transfers is their versatility in printing on a variety of fabrics, including cotton, polyester, and their blends. This adaptability allows for a broader range of applications, making it perfect for everything from casual tees to stylish hoodies. As consumer demand for customized apparel grows, DTF printing technology is poised to meet that demand with its ability to cater to diverse fabric types.

In addition to fabric versatility, DTF transfers offer cost-effectiveness for small production runs. Compared to traditional screen printing, which often incurs higher setup costs, DTF allows businesses—especially startups and small manufacturers—to create custom designs without significant upfront investments. This financial flexibility enables more entrepreneurs to enter the custom apparel market, competing effectively while exploring creative opportunities.

Exploring Key Advantages of DTF Printing Technology

DTF transfer technology boasts several advantages that make it a game-changer in the custom apparel industry. A major benefit is its capacity for producing vibrant, detailed prints that capture intricate designs with clarity. Advances in DTF ink formulations have resulted in color vibrancy and durability, ensuring designs remain striking and intact after multiple washes. This high-quality output not only enhances the appeal of custom products but also encourages repeat business as customers appreciate the longevity of their apparel.

Moreover, DTF transfers require no weeding, presenting a time-saving aspect that traditional printing methods lack. Since the excess materials are left intact on the film, production becomes swifter, allowing businesses to efficiently manage order fulfillment. As timelines shorten and productivity increases, this advantage creates opportunities for companies to respond promptly to market demands, further solidifying DTF’s reputation in the fast-paced apparel industry.

Recent Developments Enhancing DTF Transfer Quality

The DTF printing landscape has seen remarkable technical advancements that continuously improve the quality of transfers. Innovations in ink technology enhance color vibrancy, enabling producers to achieve eye-catching prints that stand out in a competitive marketplace. As colors become richer and designs more striking, this advancement propels DTF transfers as a top choice for professional printers seeking high-quality outputs.

Additionally, improvements in the washability of fabrics printed with DTF transfers have bolstered customer confidence. Enhanced bonding techniques ensure that prints can withstand numerous laundry cycles without deteriorating. This longevity not only elevates customer satisfaction but also promotes customer loyalty, as buyers are likely to return for more durable, high-quality products that align with their preferences. The ongoing enhancements assure businesses and consumers that DTF technology is continuously advancing.

The Market Impact of DTF Printing

DTF printing technology is reshaping the custom apparel market by fostering increased demand for personalized products. This direct-to-film method allows brands to diversify their offerings significantly; custom designs are now accessible to a broader audience. Companies embracing DTF printing experience heightened customer interest and engagement due to the unique, individualized products it facilitates, effectively transcending traditional mass-produced apparel.

Additionally, DTF transfers have leveled the playing field for smaller manufacturers and startups. With lower entry costs and a straightforward printing process, more businesses can compete in the custom apparel arena. As DTF becomes more mainstream, companies report increased orders and enhanced competitiveness, particularly among those that leverage the technology to respond to trends in the personalization of fashion.

User Experiences with DTF Transfers

Customer testimonials highlight the growing preferences towards DTF transfers. Many users emphasize the ease of use that DTF technology offers, allowing even beginners to navigate the printing process successfully. The simplicity of the method facilitates quick learning curves, enabling new entrants into the custom apparel market to produce high-quality results without extensive training.

Professionals who switch to DTF printing often report consistent results that exceed their expectations. The ability to achieve fine details and rich colors elevates their product offerings, providing a competitive edge in an increasingly crowded market. As user experiences continue to reflect satisfaction with quality and efficiency, DTF technology solidifies its place as a revolutionary innovation in apparel printing.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a modern custom apparel printing technique where designs are printed on a special film and then transferred onto garments using heat. This process allows for vibrant colors and detailed designs, making it ideal for personalizing various types of apparel.

What are the advantages of using DTF printing technology for custom apparel?

DTF printing technology offers several advantages, including versatility in fabric application, no weeding required after printing, and cost-effectiveness for small production runs. These benefits make DTF transfers an attractive option for businesses looking to create high-quality, personalized clothing.

How does the DTF transfer process compare to traditional printing methods?

The DTF transfer process stands out from traditional printing methods by eliminating the need for weeding and offering lower setup costs, especially beneficial for small batches. Additionally, DTF captures intricate details and vibrant colors, ensuring superior quality in custom apparel, unlike typical screen printing.

Why are DTF transfers increasingly popular in the custom apparel market?

DTF transfers are becoming popular due to their adaptability to various fabrics, user-friendliness for beginners, and improved production times. As demand for personalized products grows, DTF technology enables manufacturers to meet customer expectations with high-quality, visually appealing designs.

What recent advancements have been made in DTF transfer technology?

Recent advancements in DTF transfer technology include enhancements in ink formulations for better color vibrancy, improved washability of prints, and faster production setups. These developments have significantly increased the durability and appeal of DTF transfers, solidifying their place in the custom apparel market.

Can DTF transfers be applied to all types of fabrics?

Yes, DTF transfers can be applied to a wide range of fabrics, including cotton, polyester, and fabric blends. This versatility allows businesses to create diverse custom apparel tailored to different consumer preferences, making DTF an ideal solution for various apparel types.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | A modern printing method using special film to transfer vibrant designs onto garments using heat. |

| DTF Process Steps | 1. Design Creation 2. Printing on Film 3. Applying Adhesive Powder 4. Heat Pressing 5. Peeling the Film. |

| Advantages of DTF Transfers | 1. Versatility 2. No Weeding Required 3. Cost-Effective for Small Runs |

| Recent Developments in DTF Technologies | 1. Enhanced Color Vibrancy 2. Improved Washability 3. Faster Production Times |

| Market Impact | Increased customer satisfaction, higher orders, and competitiveness, especially for small businesses. |

| User Experiences | Beginners find it user-friendly while professionals achieve high-quality results. |

Summary

DTF Transfers represent a pivotal advancement in the custom apparel sector. This technique not only fosters creativity with its ability to produce intricate designs on various fabrics but also caters to businesses seeking economical and quick solutions for custom orders. The combination of versatility, ease of use, and ongoing technological improvements positions DTF Transfers as a leading choice for both new and established players in the market. As we continue to witness its evolution, DTF Transfers promise to redefine personalization in fashion with superior quality and vibrant results.