The DTF Gangsheet Builder is revolutionizing the printing landscape, offering businesses a modern alternative to traditional printing methods. This innovative technology allows for seamless Direct-to-Film (DTF) printing, enabling the creation of vibrant designs with unmatched efficiency. Unlike screen printing, which can be labor-intensive and time-consuming, DTF printing provides a cost-effective printing solution that accommodates various materials and intricate artwork. With a growing focus on quality and speed, the DTF Gangsheet Builder is quickly becoming the go-to choice for those seeking a blend of versatility and affordability in printing technologies. As the demand for high-quality prints increases, understanding the benefits of DTF printing could be key to remaining competitive in the market.

Exploring the DTF Gangsheet Builder introduces us to a cutting-edge method of printing that efficiently combines design and functionality. This technique, also known as Direct-to-Film printing, enables creators to apply intricate designs onto garments and fabrics with ease. In contrast to conventional methods, such as screen and direct-to-garment printing, the DTF approach streamlines the workflow while maintaining exceptional quality. The integration of this technology into printing businesses not only offers a more refined output but also proves to be a financially savvy alternative, allowing printers to cater to the modern consumer’s needs with cost-effective printing solutions. As we investigate further, it becomes clear that DTF printing stands at the forefront of contemporary printing technologies.

The Rise of DTF Printing Technology

DTF printing technology has emerged as a game-changer in the world of printing, offering innovative solutions that challenge the status quo of traditional methods like screen and direct-to-garment printing. At its core, DTF involves printing designs on a specialized film that can be transferred onto fabric using heat and pressure. This method not only allows for eye-catching, vibrant colors, but also supports intricate designs without the limitations imposed by other techniques. Unlike traditional printing methods, DTF provides a streamlined approach that caters to the demands of modern businesses and consumers seeking custom and personalized products.

Furthermore, as the digital landscape expands, DTF printing technology is gaining traction among small to medium-sized enterprises. These businesses appreciate the ability to produce high-quality prints on-demand without the hefty setup costs associated with traditional screen printing. More so, the DTF process is adaptable to a wide range of fabrics, from cotton to blends, making it a versatile option in the competitive printing market where innovation is key.

Maximizing Production Efficiency with DTF Gangsheet Builders

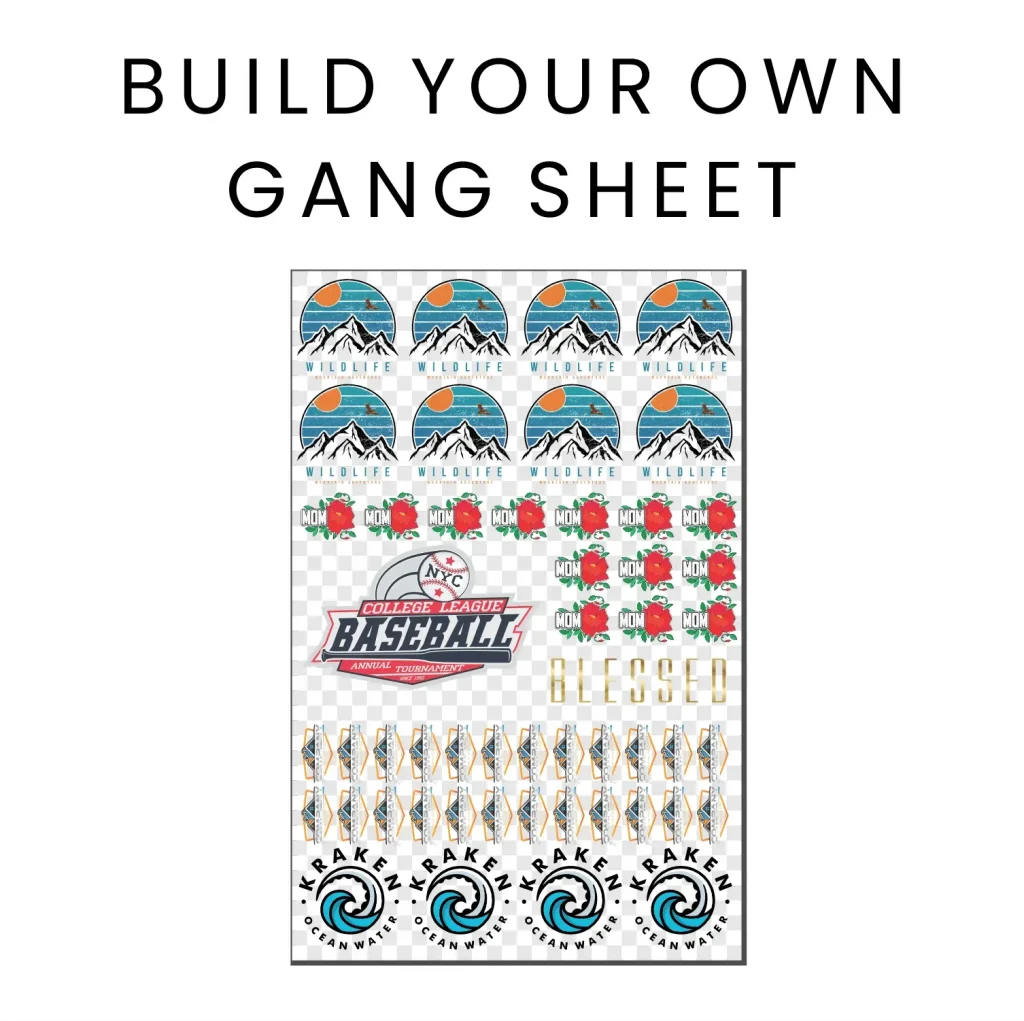

One of the critical advantages of using DTF Gangsheet Builders is the enhancement of production efficiency. This technology allows multiple designs to be printed simultaneously, thereby drastically reducing turnaround times. Traditional methods often require extensive setup processes for each new design, making them less suitable for businesses that need rapid fulfillment of orders. With DTF Gangsheet Builders, the time saved in production translates directly into increased output and revenue, allowing businesses to handle higher volumes without compromising on quality.

Moreover, the efficiency of DTF printing significantly benefits businesses operating on tight deadlines or those facing fluctuating order volumes. The ability to print on-demand allows for better inventory management and reduces the risk of overproduction. This operational advantage, combined with a cost-effective printing process, positions DTF Gangsheet Builders as a pivotal tool for modern print shops aspiring to optimize their workflows and meet customer demands effectively.

Cost-Effectiveness in Modern Printing Solutions

In today’s economically driven marketplace, businesses are constantly seeking cost-effective solutions, and DTF Gangsheet Builders offer just that. By minimizing material waste and reducing the cost per print, DTF technology provides an attractive alternative to traditional methods such as screen printing. Instead of investing in multiple screens for numerous designs, businesses can achieve high-quality prints using a single transfer film, thereby considerably lowering production costs.

Additionally, this cost-saving capability empowers small businesses and startups to enter the market without the heavy financial burden typically associated with traditional printing setups. As they capitalize on the affordability of DTF printing, these businesses can experiment with various designs and applications, facilitating greater creativity and innovation without the risk of overspending.

Durability and Quality of DTF Prints

When discussing the advantages of different printing methods, durability and quality are paramount. DTF prints are renowned for their resiliency; they can withstand repeated washes without fading, cracking, or peeling. This enduring quality makes DTF printing highly appealing for apparel manufacturers and businesses focused on producing long-lasting products. By providing vibrant end-results that maintain their integrity over time, DTF printing sets a new standard for print quality.

In contrast, traditional printing methods such as screen printing can sometimes fall short in terms of longevity, especially if not executed properly. While traditional methods have their strengths, the demand for high-quality, durable prints has encouraged many businesses to pivot towards DTF technology as a reliable printing solution that meets the expectations of today’s consumers.

Material Versatility: A Key Benefit of DTF

The expansive material compatibility offered by DTF printing is another essential benefit that distinguishes it from traditional methods. Having the capability to print on a diverse array of fabrics, including cotton, polyester, and blends, gives DTF printers an edge in versatility. This allows businesses to cater to a wider audience by producing customized products that appeal to different customer preferences, which is particularly advantageous in industries such as fashion and promotional merchandise.

In comparison, traditional methods often have limitations regarding the types of materials that can be used, depending on the inks utilized. Screen printing, for instance, predominantly requires specific types of fabric that can withstand the heat and inks used in the printing process. DTF, therefore, provides a more inclusive and flexible alternative that enables businesses to explore innovative designs across various fabric types without compromising on quality.

Navigating the Future: Adapting to Trends in Printing

As the printing landscape evolves, it is essential for businesses to stay abreast of emerging technologies and shifting consumer preferences. With the rising popularity of DTF printing, many smaller print shops are making the transition, drawn by its low startup costs and minimal operational overhead. This trend reflects a broader movement within the printing industry towards more agile and efficient production methods that align with contemporary market demands.

In contrast, traditional printing methods continue to maintain a stronghold in specific niches, particularly where large-scale production is essential. Large operations often justify the higher initial investments associated with traditional setups due to their ability to produce consistent quality at scale. However, by understanding these trends and adapting to the needs of their target markets, businesses can position themselves for long-term success in an ever-changing printing environment.

Frequently Asked Questions

What is DTF Gangsheet Builder and how does it compare to traditional printing methods?

The DTF Gangsheet Builder is a revolutionary tool in DTF (Direct-to-Film) printing technology that allows users to print multiple designs on a single sheet efficiently. Unlike traditional printing methods such as screen printing, which require more setup and time for each design, the DTF Gangsheet Builder streamlines production, making it ideal for businesses needing quick, cost-effective printing solutions.

How does DTF printing improve efficiency over traditional screen printing?

DTF printing, particularly with a DTF Gangsheet Builder, allows for the printing of several designs simultaneously without the need for individual setups for each one. This significantly enhances efficiency compared to traditional screen printing, where extensive setup for each color and design can slow down production.

Is DTF Gangsheet Builder a cost-effective printing option?

Yes, the DTF Gangsheet Builder is considered a cost-effective printing option. It reduces material waste by maximizing the use of printer sheets, which lowers overall costs, especially for small to medium orders. This is particularly advantageous when compared to traditional screen printing methods that have higher setup costs and limitations on order sizes.

What makes DTF printing superior in terms of quality compared to traditional printing methods?

DTF printing using a Gangsheet Builder produces vibrant and durable prints that can endure multiple washes without fading or peeling. This quality surpasses many traditional methods, such as screen printing, which may face issues with durability over time, especially on certain fabric types.

Can DTF Gangsheet Builders be used on different types of fabrics?

Absolutely! DTF Gangsheet Builders offer greater versatility by allowing printing on a wide array of fabrics including cotton, polyester, and blends. This flexibility is a significant advantage over traditional printing methods, particularly screen printing, which often has limitations based on ink types and compatible fabrics.

What should I consider when choosing between DTF printing and traditional printing methods?

When deciding between DTF printing with a Gangsheet Builder and traditional printing methods, consider factors such as your production volume, design complexity, material compatibility, and budget. DTF printing excels in lower quantity, diverse design needs, whereas traditional methods are more suited for high-volume orders with intricate details.

| Key Points | DTF Gangsheet Builder | Traditional Methods |

|---|---|---|

| Overview | A modern printing technique that allows printing designs on special film for versatile fabric applications. | Established methods like screen printing and DTG printing, known for their reliability and consistency. |

| Efficiency | Enables printing multiple designs in one operation, significantly speeding up production. | Involves lengthy setup processes for each design, ideal mainly for large orders. |

| Cost Effectiveness | Reduces material waste, lowering costs for smaller orders and varied designs. | Higher costs per design due to labor-intensive processes and resources used in traditional setups. |

| Quality and Versatility | Produces vibrant and durable prints on a wide range of fabrics, making it very versatile. | Offers consistent results for large runs but is limited in fabric compatibility. |

Summary

DTF Gangsheet Builder is becoming a popular choice as it meets the demands of modern printing needs effectively. As printing technologies evolve, businesses face the critical decision of selecting the appropriate method that aligns with their operational requirements. The DTF Gangsheet Builder stands out for its speed, versatility, and cost efficiency, making it ideal for small to medium-sized operations looking for flexibility. Traditional methods, while still reliable for large orders, may not provide the same adaptability and cost savings that newer technologies like DTF offer. Recognizing their unique advantages allows businesses to make informed choices in their printing strategies.