In the ever-evolving world of printing technology, **DTF transfers** (Direct-to-Film transfers) stand out as a game-changer for those passionate about custom apparel printing. This innovative approach allows creators, from hobbyists to small business owners, to produce high-quality designs on a variety of fabrics with remarkable precision. With its ability to transfer intricate images seamlessly onto materials such as cotton and polyester, DTF printing offers unparalleled versatility compared to traditional methods. In this guide, we’ll explore how to master DTF design techniques, optimize material choices, and stay ahead of market trends, empowering you to elevate your creative projects. Dive in as we uncover everything you need to know to harness the full power of DTF technology and transform your textile visions into reality.

Direct-to-Film printing, commonly referred to as DTF, represents the forefront of modern techniques in custom clothing production. This advanced printing method is rapidly gaining popularity due to its ability to produce vibrant, durable designs that adhere effortlessly to various fabric types. With its focus on high-resolution imagery, DTF technology allows for exceptional detail and clarity, making it an ideal choice for aspiring apparel creators. As this technology continues to advance, mastering design approaches and understanding material applications become essential skills for anyone looking to thrive in the custom apparel landscape. By embracing these innovative strategies, both hobbyists and established brands can unlock new levels of creativity and product quality.

The Benefits of DTF Transfers for Custom Apparel

DTF transfers have ushered in a new era for custom apparel printing, offering numerous benefits that cater to both hobbyists and small business owners. One notable advantage is their versatility; DTF technology enables printing on a wide range of fabrics, from cotton to polyester and even non-woven materials. This flexibility allows custom apparel creators to expand their product offerings, improving customer satisfaction with diverse garment choices. The high resolution of DTF prints means vibrant colors and intricate designs that stand out, enhancing the appeal of any clothing line.

Another critical benefit of DTF transfers is the durability of the prints. Unlike traditional methods that may result in fading or peeling over time, DTF prints maintain their stunning quality even after repeated washing. This durability not only assures customers of the longevity of their purchases but also reduces the need for reprints, which can save businesses time and resources. As a result, DTF printing has become increasingly popular among entrepreneurs looking to make a mark in the competitive world of custom apparel.

Exploring the DTF Printing Process

The DTF printing process is characterized by its simplicity and efficiency, making it an attractive option for those new to the world of custom apparel. To begin, a design is created using software like Adobe Illustrator, where the artwork is meticulously crafted to ensure high-quality output. Once the design is finalized, it is printed onto a special DTF film using a high-resolution inkjet printer. This process allows for rich color saturation and precise detailing, key factors that contribute to the appeal of the final product.

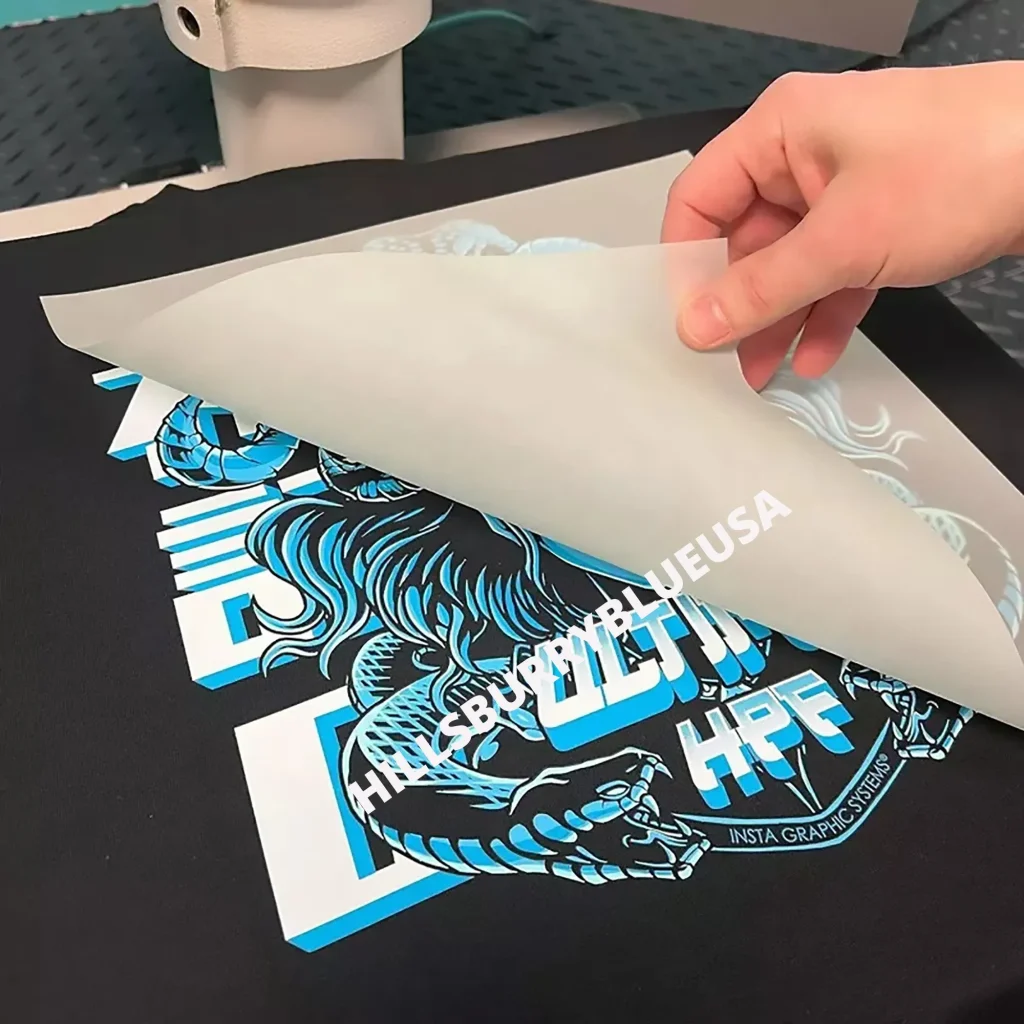

After the design is printed, it undergoes a transfer process where the film is applied to the fabric using a heat press. This step creates a strong bond between the print and the textile, ensuring durability and wash resistance. The entire process is not only efficient but also relatively cost-effective, allowing for short production runs without sacrificing quality. As more creators become aware of the potential benefits and straightforward nature of DTF printing, the technique continues to gain momentum in the custom apparel marketplace.

Key Materials Required for DTF Printing

A successful DTF transfer project begins with the right materials, particularly the DTF film and adhesive powder. The film should be specifically designed for DTF use, featuring a coating that allows for optimal ink adhesion and color vibrancy. As technology evolves, manufacturers are introducing improved films that enhance durability and washability, addressing common concerns regarding print longevity. Choosing the right type of film is crucial, as it directly impacts the final quality of the print.

In addition to the film, the adhesive powder plays a significant role in securing the print to the fabric. Recent advancements have produced formulations that provide stronger bonding without compromising the feel of the garment. By selecting high-quality materials, creators can ensure their DTF transfers not only look fantastic but also withstand the test of time. This attention to material quality can make all the difference in the perceived value of custom apparel, helping businesses stand out in a crowded market.

Popular Design Techniques for DTF Transfers

To fully harness the potential of DTF transfers, designers must employ effective design techniques that celebrate the technology’s capabilities. Utilizing design software like CorelDRAW or Adobe Illustrator allows artists to create intricate, high-resolution graphics specifically tailored for DTF applications. This software provides a platform for experimentation with color palettes and patterns, enabling designers to craft unique styles that resonate with their target audience.

Moreover, the growing community around DTF printing offers a wealth of resources and tutorials aimed at enhancing design skills. This collaborative environment fosters creativity and innovation, encouraging designers to push the boundaries of traditional design methods. By staying informed about the latest trends and sharing insights, creators can continue to refine their skills, ensuring their DTF projects are always fresh and engaging.

Understanding the Market Trends in DTF Printing

The DTF transfer market has experienced significant growth recently, primarily due to its appeal among small business owners and individual crafters. As the custom apparel industry becomes more accessible, DTF printing shines as a cost-effective way to produce high-quality garments. The technology’s lower entry costs compared to other methods, like screen printing or DTG, make it highly attractive to aspiring entrepreneurs looking to start their apparel line.

Additionally, market trends indicate a rising demand for personalized products, with consumers increasingly seeking unique designs that reflect their individual tastes. DTF transfers cater to this desire, offering the ability to create bespoke pieces that help brands stand out in a saturated market. As more creators share their DTF projects online, the visibility and desirability of custom apparel continue to rise, further solidifying DTF transfers’ place in the future of printing technology.

The Future of DTF Transfers in the Printing Industry

Looking ahead, the future of DTF transfers appears promising as the technology continues to evolve. Innovations in ink formulations and printing techniques are expected to enhance quality and sustainability, driving increased interest from environmentally-conscious consumers. As the printing industry shifts toward eco-friendly practices, DTF printing is well-positioned to thrive, given its potential for using non-toxic inks and recyclable materials.

Furthermore, as more educational resources become available, aspiring printers and designers will gain the knowledge and confidence necessary to explore DTF technology fully. The convergence of creativity, technological advancement, and community support will likely lead to a flourishing market for DTF transfers, making it a vital player in the broader landscape of custom apparel printing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a popular printing technology that involves printing designs onto a special film using high-resolution inkjet printers. The printed film is then applied to fabric using heat press, allowing vibrant images to transfer seamlessly onto various materials such as cotton, polyester, and blends.

What are the benefits of using DTF printing for custom apparel?

DTF printing offers numerous benefits for custom apparel, including versatility with different fabric types, excellent color vibrancy, and durability. The prints can withstand multiple washes without peeling or fading, making DTF a reliable choice for high-quality, long-lasting custom designs.

How do I choose the right materials for DTF transfers?

Choosing the right materials for DTF transfers is essential for success. Look for high-quality DTF films and adhesive powders designed for optimal adhesion and color reproduction. Eco-friendly inks are also a growing trend, providing sustainable options that do not compromise on print quality.

What design software is best for creating DTF designs?

Adobe Illustrator and CorelDRAW are among the best software choices for creating designs tailored for DTF transfers. These programs offer advanced features that allow designers to craft high-resolution artwork with a wide range of color combinations and detailed patterns.

Are DTF transfers suitable for small businesses or hobbyists?

Yes, DTF transfers are highly suitable for both small businesses and hobbyists. The low entry costs and ease of access to DTF printing technology make it an ideal option for those looking to create custom apparel, whether for personal use or as a commercial venture.

What are some current market trends in DTF printing?

Current market trends in DTF printing include a surge in interest from small business owners and crafters, increased accessibility due to lower entry costs, and the rise of eco-friendly printing practices. Social media has also played a significant role in showcasing DTF projects and boosting its popularity.

| Section | Key Points |

|---|---|

| Introduction | Overview of DTF transfers and their significance for hobbyists and businesses. |

| Understanding DTF Technology | DTF printing involves transferring designs onto fabrics through heat press, accommodating various materials unlike DTG printing. |

| Material Choices | Importance of selecting the right films and adhesive powders; trend towards eco-friendly inks. |

| Design Techniques | Use of software like Adobe Illustrator for high-quality designs; community resources available for learning. |

| Market Trends | Growth driven by small businesses; low entry costs; increased exposure through social media. |

Summary

DTF transfers represent a transformative leap in print technology, characterized by their adaptability to various fabrics and ability to create high-quality prints. By understanding the fundamental aspects of DTF transfers, such as technology, materials, design techniques, and current market trends, both amateur crafters and professionals can take full advantage of this innovative method. As the print-on-demand industry continues to evolve, DTF transfers are becoming an essential tool for entrepreneurs, allowing them to bring their creative visions to life while meeting consumers’ demands for personalized products.