DTF Transfers, or Direct-to-Film transfers, are leading a remarkable transformation in the world of custom apparel and fabric printing. By combining advanced printing technology with ease of use, DTF is enabling businesses to produce vivid, high-quality designs on various textiles efficiently. This innovative method stands out in the competitive market for its ability to deliver stunning prints while simultaneously being cost-effective and environmentally friendly. As the demand for sustainable printing options grows, DTF Transfers provide a solution that not only meets this desire but also enhances the creativity and versatility of fabric printing applications. In this comprehensive guide, we will delve deeper into how this distinctive printing technology is reshaping the landscape of the textile industry.

When we talk about Direct-to-Film (DTF) transfers, we’re exploring a new frontier in textile printing that emphasizes customization and quality. This state-of-the-art approach allows for exceptional details and vibrant colors, making it an ideal choice for a range of applications from sports gear to fashion wear. With its user-friendly setup and efficient process, DTF caters perfectly to small businesses and creative individuals eager to expand their product lines. This printing innovation not only champions sustainability with its reduced waste footprint but also promises a surge in the popularity of personalized products. As we continue to explore the intricacies of fabric printing technologies, the impact of DTF will be a key defining factor in the industry.

Understanding DTF Transfers and Their Process

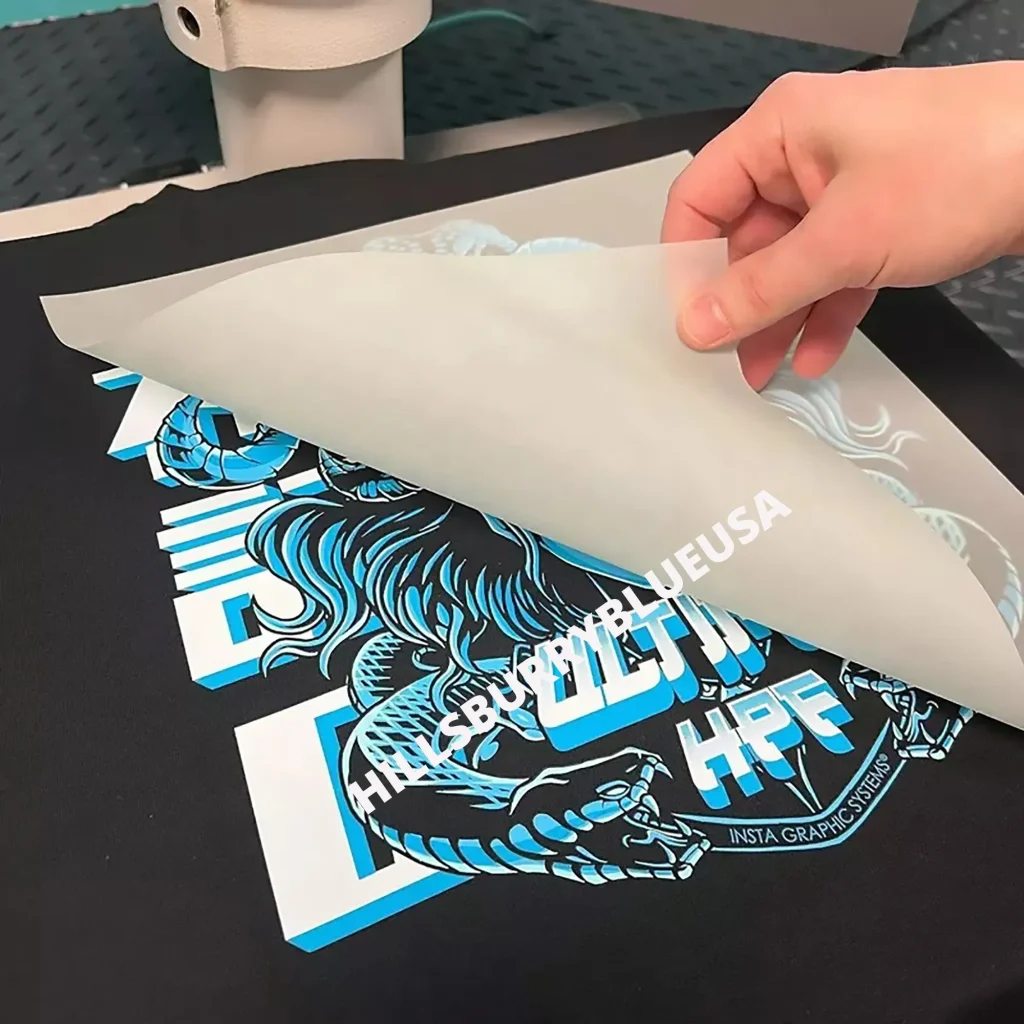

DTF transfers, or Direct-to-Film transfers, represent a significant shift in the fabric printing landscape. This innovative technique involves printing high-quality designs onto a special film, which can then be heat transferred onto a variety of fabrics. The process begins with the application of specialized inks that are rich in color and suitable for high-resolution prints, making it ideal for custom apparel, sportswear, and home textiles. Businesses can leverage this technology to produce products at a scale that aligns with consumer demand while maintaining exceptional print quality.

Unlike traditional fabric printing methods, DTF transfers are notable for their flexibility and ease of use. The ability to easily switch between different designs without extensive setup makes DTF a favorable option for small businesses and independent artists. Moreover, the quick-drying nature of the DTF printing process allows for faster turnaround times, thereby enhancing productivity. As the textile industry continues to evolve, DTF printing technologies are proving essential for meeting consumer expectations for customization and quality.

The Benefits of DTF Printing for Custom Apparel

One of the standout advantages of DTF printing is its ability to produce intricate designs on custom apparel without the limitations often associated with traditional methods like screen printing. With DTF technology, artists and businesses can explore bold colors, gradients, and complex patterns that add a unique flair to their offerings. This capability not only appeals to individual consumers looking for personalized products but also allows for collaboration between designers and clothing brands seeking to differentiate themselves in a saturated market.

Moreover, DTF printing is known for its durability, providing prints that withstand washing and wear better than many other techniques. This aspect is crucial for consumers who expect their custom textiles to maintain vibrancy over time. The sustainable aspect of DTF printing also attracts eco-conscious customers, as this process generates less waste compared to conventional printing methods. Hence, businesses can capitalize on both quality and environmental responsibility, making DTF transfers a preferred choice for creating custom apparel.

Sustainable Printing Solutions with DTF Technology

Sustainability in fabric printing is more important than ever, and DTF technology provides a pathway for businesses to adopt greener practices. Many printing companies are now using eco-friendly inks specifically designed for DTF transfers, which contain fewer harmful chemicals. This focus on sustainability not only benefits the environment but also enhances brand reputation, as consumers are increasingly attracted to companies that prioritize eco-friendly practices.

In addition, the DTF printing process uses significantly less ink than traditional methods, reducing overall waste. This efficiency makes DTF a sustainable alternative for businesses looking to minimize their environmental impact while still providing high-quality results. As customers seek out brands committed to sustainability, embracing DTF technology can position a business as a leader in the movement towards responsible printing solutions.

Advancements in DTF Printing Technology

Recent advancements in DTF printing technology have led to the introduction of faster and more efficient printing machines. These modern printers utilize advanced inkjet technology, which results in improved adhesion and print quality on various fabric types. As features such as quicker dry times and higher resolution capabilities continue to evolve, businesses are able to streamline their operations and respond more promptly to market demands.

Additionally, innovations in the formulation of inks have enhanced the vibrancy and longevity of prints produced through DTF transfers. Improved ink formulations enable deep pigmentation that remains bold even after multiple washes. This development is crucial for businesses aiming to attract and retain customers through high-quality offerings, thereby reinforcing the viability of DTF technology as a great investment for anyone in the fabric printing industry.

The Growing Market for DTF Transfers

The market for DTF transfers has experienced significant growth, particularly in the custom apparel segment. As more consumers seek personalized products, the demand for technologies that can accommodate quick turnaround times without sacrificing quality has surged. This uptick in interest is driving more businesses to adopt DTF printing solutions as a means of staying competitive in the evolving landscape of textile and apparel printing.

As e-commerce continues to thrive and consumer preferences shift towards unique and customized items, DTF printing remains at the forefront of this expansion. Owners of small businesses can leverage DTF technology to efficiently meet increasing consumer demands for customized textiles, while bigger companies benefit from the cost-effective nature of DTF transfers in scaling their production. The potential for further market penetration of DTF technology and its applicability across various fabric printing needs remain promising.

Why Choose DTF Transfers Over Traditional Printing Methods?

Choosing DTF transfers over traditional printing methods presents various advantages that can significantly benefit businesses in the fabric sector. For starters, DTF printing reduces setup time, requiring minimal preparation compared to screen printing or direct-to-garment printing. This efficiency allows businesses to adapt swiftly to changing market demands and pivot towards producing trending designs with ease.

Moreover, the ability to print on a wide range of fabrics increases the versatility of DTF transfers, accommodating different customer needs and preferences. With DTF technology, intricate designs and vibrant colors can be achieved without the limitations of other printing techniques, providing a significant advantage for brands looking to offer unique products. In an era where customization is king, DTF printing stands tall as a leading option for modern fabric solutions.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a modern fabric printing technology that allows users to print vibrant designs directly onto a specialized film. This film is then transferred onto various fabric types, such as cotton and polyester, using heat. This method provides high-quality, durable prints with excellent color accuracy, making it popular for custom apparel and fabric applications.

What are the advantages of using DTF transfers for fabric printing?

DTF transfers offer numerous advantages, including versatility across different fabric types, easy setup and operation, and the ability to produce intricate designs with vibrant colors. Additionally, DTF printing generates less waste compared to traditional methods and is more cost-effective for small businesses looking to create custom apparel.

Is DTF printing suitable for small businesses and independent creators?

Yes, DTF printing is ideal for small businesses and independent creators due to its low initial investment and straightforward setup process. The technology allows them to efficiently produce high-quality custom apparel and textiles without the need for extensive training or complicated equipment.

How does DTF printing contribute to sustainable fabric printing practices?

DTF printing contributes to sustainable fabric printing practices by utilizing eco-friendly inks that have a lower environmental impact. The technology also reduces waste by using only necessary amounts of ink, making it a more responsible choice for businesses aiming to market sustainable products.

What types of fabric can be used with DTF transfers?

DTF transfers can be used on a wide range of fabrics, including cotton, polyester, and blended materials. This versatility makes DTF printing an excellent option for creating custom apparel, sports gear, and various home textile products.

Will DTF printing technology continue to grow in popularity?

Yes, DTF printing technology is expected to see significant growth in popularity, driven by increasing consumer demand for personalized and custom textile products. As more businesses adopt DTF transfers, advancements in printing technology and eco-friendly options will further enhance the appeal of this innovative fabric printing method.

| Key Features | Description |

|---|---|

| Versatility in Fabric | Suitable for a wide variety of fabrics including cotton, polyester, and blended materials, perfect for custom apparel, home textiles, and sports gear. |

| Easy Setup and Operation | Requires low investment and minimal learning curve, making it accessible for small businesses and independent artists. |

| High-Quality Output | Offers high detail, vibrant colors, and excellent color accuracy, capable of intricate designs. |

| Innovation in Printing Technology | Modern DTF printers use advanced inkjet technology for better quality prints, improved adhesion, and durability. |

| Accessibility for Small Businesses | Lower costs and ease of use make it an attractive option for new entrants in the fabric printing industry. |

| Environmental Considerations | Focus on eco-friendly DTF inks to meet consumer demand for sustainable products. |

| Market Growth and Adoption | Predicted significant rise in adoption rates due to personalized products and custom textiles demand. |

| Reduced Waste | Generates significantly less waste than screen printing, making it a more sustainable option. |

| Complex Designs Made Easy | Allows for high-quality, multi-color designs and intricate details that are difficult to achieve with other methods. |

Summary

DTF Transfers are revolutionizing the way we print on fabric by offering innovative solutions that combine accessibility, quality, and sustainability. This new printing technology stands out in the fabric industry due to its versatility across different fabric types, ease of use for small businesses, and potential for vibrant, high-quality output. As the market continues to grow, driven by the demand for personalized products, DTF Transfers are rapidly becoming the preferred choice for custom textiles. With a focus on eco-friendly practices and ongoing innovations in printing technology, DTF is set to lead the future of fabric printing.