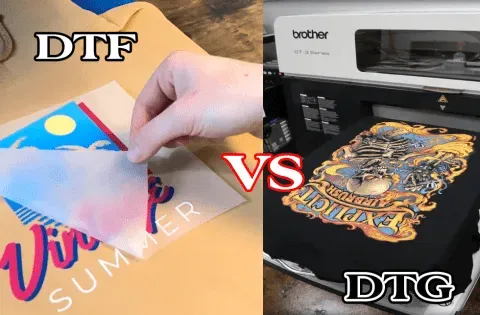

When it comes to customizing apparel and textile products, the choice between DTF vs DTG often comes up for business owners navigating the world of printing technologies. Direct to Film (DTF) and Direct to Garment (DTG) are two innovative printing methods that cater to varying needs in the industry, each possessing distinct advantages. A comprehensive printing methods comparison shows that while DTG delivers exceptional quality with intricate details and vibrant colors, DTF printing boasts increased versatility and efficiency, particularly for larger batches. Understanding the DTF printing advantages versus the renowned DTG printing quality is crucial for businesses looking to establish themselves in a competitive market. By exploring these methods side by side, you can make an informed decision that aligns with your operational goals and audience expectations.

In the competitive landscape of textile printing, two prominent methods have emerged: Direct to Film (DTF) and Direct to Garment (DTG). These alternative printing technologies are reshaping how designs are applied to fabric, offering unique benefits to modern apparel businesses. DTF printing, for instance, emphasizes adaptability across various materials, while DTG printing is celebrated for its high-definition output and soft tactile feel. As companies evaluate their production strategies, understanding the distinctions between DTF and DTG becomes paramount, illuminating the best choices for both small runs and larger orders.

Understanding Direct to Garment (DTG) Printing

Direct to Garment (DTG) printing represents a significant leap in the textile printing process. This method employs cutting-edge inkjet technology to apply designs directly onto the fabric surface, allowing for a level of detail that is hard to replicate. DTG printing is particularly effective for intricate and colorful artwork, making it a favorite among graphic designers and businesses with a focus on high-quality apparel. The end result is not just visually striking but also soft to the touch, as the inks penetrate the fibers of the fabric rather than sitting on top, ensuring comfort for the wearer.

Moreover, DTG technology has evolved to become more user-friendly and efficient. Modern DTG printers can handle a variety of fabric types, though they particularly excel with 100% cotton. Brands focusing on personalized fashion often prefer DTG due to its ability to cater to that niche market. With trends shifting towards sustainable and custom apparel, DTG remains a popular choice, especially among businesses that prioritize quality and customer satisfaction.

Frequently Asked Questions

What is the main difference between DTF and DTG printing?

The main difference between DTF (Direct to Film) and DTG (Direct to Garment) printing lies in their application methods. DTG uses inkjet technology to print directly on fabric, making it ideal for detailed designs on cotton. In contrast, DTF prints designs onto a special film that is then heat transferred onto various materials, offering broader fabric compatibility.

Which printing method provides better quality prints: DTF or DTG?

DTG printing typically offers superior quality prints, especially for intricate designs and vibrant colors, as the ink penetrates the fabric fibers. DTF printing has improved but may not match the detail of DTG unless for simpler designs, where it performs well with bold prints.

How does the speed of DTF compared to DTG printing affect production?

DTF printing is generally faster than DTG because DTF does not require pre-treatment of fabric, making it more efficient for larger orders. In contrast, DTG’s requirement for pre-treatment can slow down production times, especially for bulk runs.

What types of fabrics can be used for DTF and DTG printing?

DTG printing works best on 100% cotton fabrics, while DTF printing is more versatile, capable of printing on various materials including polyester, cotton, and blends. This flexibility makes DTF suitable for a wider range of garment types.

Are there significant cost differences between DTF and DTG printing?

Yes, there are cost differences. DTG printing often requires a higher initial investment for equipment and ongoing ink costs. Conversely, DTF printing typically has a lower startup cost but includes expenses for films and transfers, making it appealing to startups.

What are the durability factors for prints created using DTF vs. DTG?

Both DTF and DTG prints are durable when properly cared for. Advances in DTF technology have improved its wash and wear resistance, making both methods capable of delivering long-lasting quality, especially when the final products are maintained correctly.

| Key Points | DTG | DTF |

|---|---|---|

| Quality of Output | High-quality, detailed designs. Soft feel on fabric. | Good color vibrancy, less intricate detail but effective for bold prints. |

| Production Speed | Slower due to fabric pre-treatment, particularly for larger orders. | Faster, skips pre-treatment, ideal for large batches. |

| Material Compatibility | Best on 100% cotton fabrics. | Versatile; can print on cotton, polyester, and blended fabrics. |

| Cost Considerations | Higher initial investment and ongoing ink costs. | Lower initial cost but additional costs for films and transfers. |

| Durability | Durable prints, albeit dependent on cotton quality. | Improving wash and wear resistance with advancements in technology. |

Summary

DTF vs DTG is a significant consideration for businesses looking to customize apparel and textiles. Direct to Film (DTF) printing offers versatility and speed, making it an efficient choice for larger batches and a variety of materials, while Direct to Garment (DTG) printing excels in producing high-quality, intricate designs primarily on cotton fabrics. Understanding these differences helps businesses align their printing strategies with customer expectations and market demands. As both technologies evolve, businesses must stay informed about their advantages and costs, allowing them to thrive in the competitive garment printing industry.