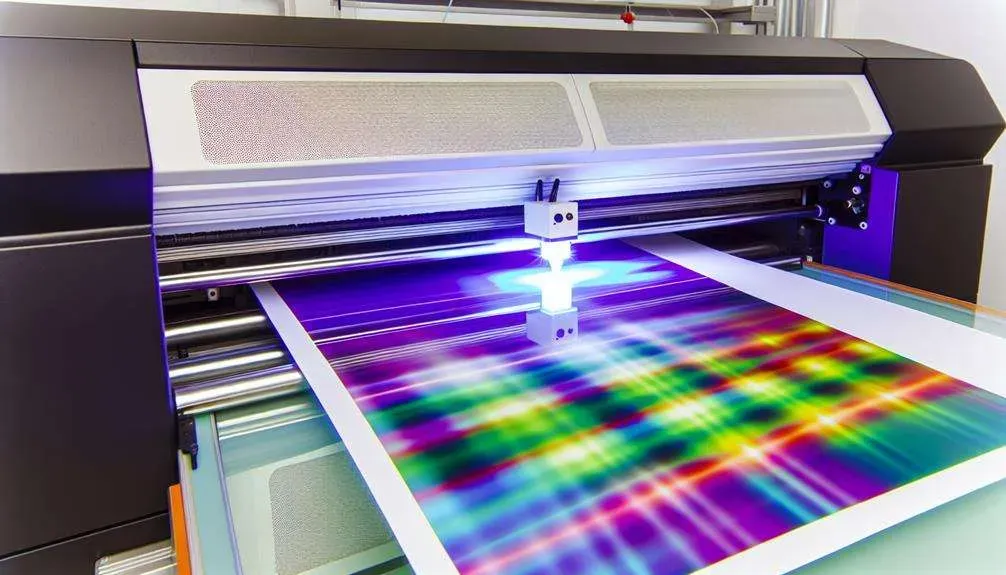

When it comes to modern printing innovations, UV DTF printing techniques stand out as a remarkable blend of efficiency and quality. This cutting-edge method, which combines UV printing with Direct-to-Film (DTF) technology, opens up new avenues for custom printing with vibrant colors and unparalleled durability. UV printing has gained immense popularity due to its ability to create stunning prints on various surfaces, making it an essential tool for businesses seeking to enhance their product offerings. With DTF printing benefits like fast production times and high-resolution image reproduction, this technique is a game changer for both small enterprises and large-scale manufacturers. As we delve deeper into the world of UV DTF printing, it’s essential to understand how these techniques revolutionize traditional approaches to graphic design and printing.

In the realm of modern print solutions, the terms UV Direct-to-Film and ultraviolet DTF printing have emerged as key players in delivering high-quality outputs. This innovative approach utilizes unique printing techniques that leverage UV light to cure inks on specialized films, leading to lightfast and durable prints ready for various applications. By exploring the advantages provided by DTF technology and its intersection with UV printing, businesses can unlock opportunities for personalized designs and creative commercial products. Emphasizing the benefits of this method, such as its versatility and efficiency, reveals why many in the industry are adopting it as a preferred choice for custom projects. Ultimately, understanding these alternatives allows users to navigate the dynamic landscape of printing with greater confidence.

Understanding UV DTF Printing Techniques

UV DTF printing stands as a hybrid approach, combining the capabilities of UV printing technology and DTF methods to deliver superior results. This innovative technique involves applying UV inks onto a special film, which is then cured using ultraviolet light. The instant curing process not only enhances the print quality by ensuring vibrant color retention but also significantly shortens the overall production time. By utilizing this technique, businesses can cater to a diverse range of substrates, tapping into the growing demand for customized and high-quality printed products.

One of the most compelling aspects of UV DTF printing techniques is their adaptability. This method is not limited to common printing surfaces; it expands into textiles, rigid materials, and even unconventional substrates such as glass or wood. The versatility this offers is invaluable for businesses looking to provide personalized merchandise or promotional items. Moreover, as UV DTF printing gains traction in the custom printing sector, brands are discovering new opportunities to engage consumers with unique, tailored products that resonate on a personal level.

Benefits of UV DTF Printing

The benefits of UV DTF printing are numerous, making it an attractive option for entrepreneurs and companies alike. One of the primary advantages is the durability of prints produced through this technology. Unlike traditional printing techniques that may suffer from fading and scratching over time, UV DTF prints maintain their vibrancy and resilience. They can withstand various environmental factors, making them suitable for both indoor displays and outdoor applications, thus expanding the market potential for businesses.

Additionally, UV DTF printing minimizes production times significantly. The instant curing capabilities allow for quick turnaround, catering to urgent client demands without sacrificing quality. As businesses strive to offer fast service amid rising competition, adopting UV DTF printing techniques can streamline operations, meet tighter deadlines, and ultimately enhance customer satisfaction. Furthermore, the use of eco-friendly inks in this process appeals to environmentally conscious consumers, enhancing brand reputation while simultaneously producing high-quality prints.

Exploring the Applications of UV DTF Printing

The applications of UV DTF printing are vast and varied, making it a versatile choice for a myriad of industries. Its utility spans promotional products, fashion apparel, custom packaging, interior décor, and more. Businesses are increasingly leveraging this printing technique to create eye-catching designs that can be tailored to individual customers, resonating strongly in the market for personalized items. From vibrant t-shirts with intricate prints to elegant packaging for premium products, UV DTF printing provides the quality and detail that modern consumers demand.

Additionally, the growing trend of customization and personalization in marketing has propelled the interest in UV DTF printing. Companies can easily produce small batches or even one-off designs without incurring significant costs, thereby accommodating niche markets and client-specific requests. This adaptability is especially beneficial given today’s consumer expectations for one-of-a-kind, engaging products, allowing businesses to stay ahead of the curve in a fast-paced, dynamic marketplace.

Recent Trends in UV DTF Printing

Keeping abreast of recent trends in UV DTF printing is crucial for anyone looking to enter this evolving field. One notable trend is the technological advancements that are continually improving the functionality and capabilities of UV DTF equipment. As manufacturers release more sophisticated printers, the quality of prints achievable with UV technology is reaching unprecedented levels. These advancements not only refine the printing process but also make UV DTF technology more accessible, particularly for small businesses and entrepreneurs.

Another significant trend is the shift towards environmentally friendly practices within the printing industry. With a growing emphasis on sustainability, many brands are embracing eco-friendly inks and materials that reduce the environmental impact during the printing process. This movement is aligned with consumer preferences, as more buyers seek brands that take responsible actions toward the planet. As UV DTF printing technologies evolve, incorporating greener practices can provide a competitive edge while attracting a more conscientious customer base.

Essential Beginner Tips for UV DTF Printing

Starting out in UV DTF printing can be overwhelming, but several essential tips can help beginners navigate this intricate field. One crucial piece of advice is investing in high-quality equipment for optimal results. While it may be tempting to choose the cheapest option, a reliable UV DTF printer will yield better-quality prints and reduce operational frustrations in the long run. Understanding the software is also vital; take the time to familiarize yourself with the controls and settings to maximize the potential of your printer.

Another significant tip for beginners is to experiment with various substrates before committing to large production runs. Each material behaves differently under UV DTF printing conditions, impacting adhesion and overall print quality. Conducting thorough tests will allow you to identify the best substrates for your unique projects, ensuring customer satisfaction and reducing wasted resources. Additionally, always be prepared to adjust ink levels and curing times based on the outcomes of your tests, as precision can make a substantial difference in the final product.

Navigating the Future of UV DTF Printing

The future of UV DTF printing is bright and offers exciting opportunities for growth and innovation in the printing industry. As this technology continues to advance, businesses that adapt to these changes will find themselves at a significant advantage. The increasing demand for customized products, along with superior print quality and durability, positions UV DTF printing as a frontrunner in contemporary printing methods. Keeping an eye on emerging trends and technologies will be vital for businesses looking to thrive.

Moreover, understanding market dynamics, such as consumer preferences and sustainability efforts, will further help companies tailor their offerings effectively. As brands embrace the unique potential of UV DTF printing, they can unlock new revenue streams and enhance customer loyalty. By investing in ongoing education and staying updated on industry developments, they can solidify their presence in a competitive landscape and ensure long-term success in the evolving world of custom printing.

Frequently Asked Questions

What is UV DTF printing and how does it differ from traditional UV printing?

UV DTF printing, or UV Direct-to-Film printing, combines UV printing technology and DTF techniques, allowing for the application of vibrant inks onto a special film that can be transferred to various surfaces. Unlike traditional UV printing that directly prints on materials, UV DTF printing enables flexibility in application and enhances production efficiency.

What are the main benefits of using UV DTF printing techniques for custom printing?

The main benefits of UV DTF printing techniques include vibrant color reproduction, exceptional detail, and high durability against scratches and environmental elements. Additionally, it offers faster production timelines compared to traditional methods, making it ideal for custom printing projects.

Can UV DTF printing be used on various substrates for custom applications?

Yes, UV DTF printing is exceptionally versatile and can be used on a wide range of substrates, from textiles and paper to glass and wood. This versatility makes it perfect for custom applications in promotional products, apparel, and decorative items.

What advancements are influencing the popularity of UV DTF printing techniques?

Recent advancements in UV DTF printing techniques include improved printing speed and quality due to technological innovations. Eco-friendly inks are also becoming popular, appealing to businesses that prioritize sustainability while meeting market demands.

How does UV DTF printing ensure durability in printed products?

UV DTF printing ensures durability through immediate curing of UV inks when exposed to UV light, creating solid, scratch-resistant prints. This process enhances the longevity of printed products, making them suitable for both indoor and outdoor use.

What tips can beginners follow to successfully utilize UV DTF printing techniques?

Beginners should invest in high-quality UV DTF printers and familiarize themselves with printing software. Experimenting with different substrates can help determine optimal adhesion and print quality, and conducting test prints before larger runs is essential for achieving desirable results.

| Key Point | Details |

|---|---|

| Overview of UV DTF Printing | A cutting-edge technique combining UV printing and DTF technology for versatile and high-quality prints on various surfaces. |

| What is UV DTF Printing? | Involves curing UV inks on special film for later transfer to substrates, ensuring durability and fast production. |

| Key Techniques and Developments | Includes ink application, versatility in materials, and fast curing times leading to high-quality results. |

| Advantages | Offers vibrant colors, detailed imagery, and durable prints suitable for various applications indoors and outdoors. |

| Applications | Used for promotional products, custom apparel, packaging, and home decor, appealing to a wide market. |

| Recent Trends | Technological advancements and eco-friendly inks are shaping the future of UV DTF printing, attracting conscious consumers. |

| Tips for Beginners | Invest in quality equipment, experiment with substrates, and conduct tests for optimal results before large runs. |

Summary

UV DTF printing techniques represent a revolutionary approach to modern printing, merging high-quality output with the flexibility of various substrates. As the technology continues to develop, it opens up vast creative and commercial opportunities for businesses in the printing industry. By mastering these techniques, newcomers can enhance their service offerings and compete effectively in a busy market. This method emphasizes durability, vibrant colors, and rapid production, making it an appealing choice for those looking to innovate and meet the demands of diverse customer needs.