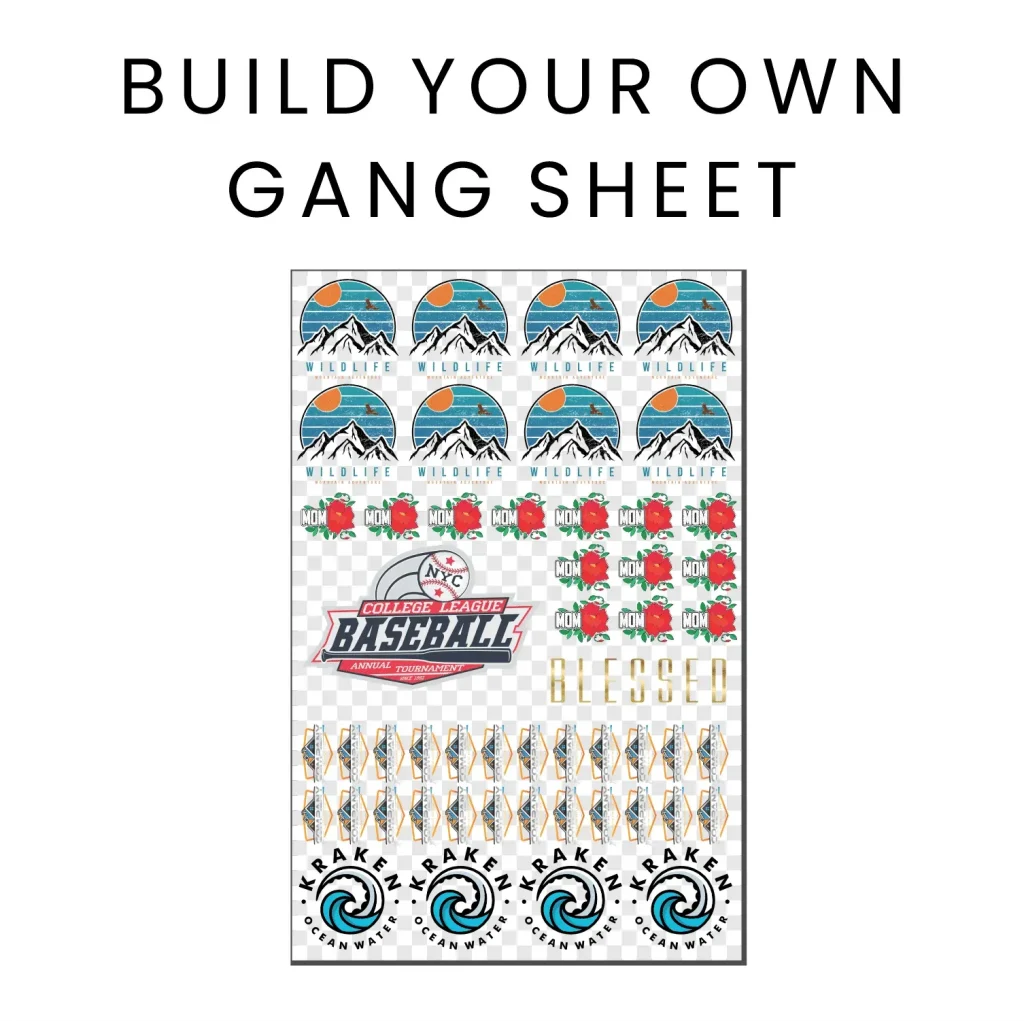

The **DTF Gangsheet Builder** is revolutionizing the world of printing by marrying efficiency with creative expression. This innovative technique optimally arranges multiple designs on a single sheet, making Direct-to-Film (DTF) printing not only cost-effective but also versatile. By leveraging gang sheets, businesses can significantly reduce material waste and speed up production times, paving the way for a more sustainable approach to printing techniques. As artists and designers explore this method, they discover endless possibilities for design optimization, allowing them to craft unique creations that stand out. Join us as we delve into the transformative power of DTF gang sheets and how they can elevate your printing projects to unprecedented heights.

Exploring the universe of the **DTF Gangsheet Builder** reveals an exciting array of printing possibilities. This method, also known as gang sheet printing, efficiently consolidates several designs onto one sheet, a practice that not only optimizes material use but also enhances the creative workflow. By harnessing various printing techniques through heat transfer, designers can achieve more with less, enriching their artistic endeavors while cutting costs. As we unpack the dynamics of gang sheets, we’ll uncover the benefits that come with this advanced approach, showcasing how innovative design can flourish in the realm of DTF printing. Prepare to unlock new levels of creativity and efficiency with this game-changing tool.

Understanding DTF Printing Techniques

DTF printing stands for Direct-to-Film printing, an advanced technique that has revolutionized how designs are transferred onto various materials. This method involves printing graphics onto a special film, which is then heat-pressed onto the desired substrate, such as fabric. Unlike traditional screen printing, DTF printing offers vivid colors and the ability to produce complex designs easily. This has made it a popular choice among apparel manufacturers, custom t-shirt businesses, and creative designers looking to bring their artwork to life effortlessly.

Incorporating techniques like color separation and layering into your DTF printing process further enhances the quality of the final products. By leveraging high-quality inks specifically formulated for DTF applications, users can achieve vibrant and long-lasting prints. This printing method not only enhances efficiency but also accommodates intricate details, thus demonstrating its versatility across various fabrics and materials.

Maximizing Efficiency with Gang Sheets

One of the standout features of DTF printing is the implementation of gang sheets, which facilitate the efficient printing of multiple designs at once. This process allows designers to utilize one sheet of material effectively, minimizing waste while maximizing creative output. By arranging different designs on a single sheet, you can significantly reduce production time and costs, as you’re not only saving on materials but also enhancing throughput.

The use of gang sheets leads to an overall improvement in workflow efficiency, especially for businesses that handle high-volume orders or custom prints. By strategically planning and optimizing your designs for gang sheets, you can ensure that every inch of material is utilized, allowing for better profit margins and a reduction in the carbon footprint associated with excess waste.

Essential Software for DTF Design Optimization

To harness the full potential of DTF printing and gang sheets, utilizing the right graphic design software is crucial. Programs like Adobe Illustrator and CorelDRAW provide advanced features that facilitate precise control over design layout and composition. These tools allow you to create templates and mockups, ensuring that every design is aligned perfectly on the gang sheet while optimizing color management and resolution settings.

Moreover, incorporating design plugins or extensions specific to DTF printing can enhance your workflow. These tools often automate repetitive tasks like color correction and alignment, saving time and reducing potential errors during the design preparation phase. As a result, investing in quality design software is not just a necessity but a strategic move towards optimizing your DTF printing process.

Selecting Quality Materials for DTF Gang Sheets

The success of DTF printing heavily relies on the choice of materials used in the process. High-quality films and inks are essential to achieve vibrant colors and durable designs. When selecting materials for gang sheets, ensure you are using films specifically designed for DTF applications, as they greatly affect the quality of the transfer and the overall durability of the print on textiles.

In addition to films, the choice of inks can also significantly influence print quality. Always opt for inks that are compatible with DTF technology to ensure that the designs achieve the best possible results. Investing in high-end supplies not only enhances the output but also reduces the likelihood of mistakes and reprints, which can save both time and money in the setup and production stages.

Implementing Effective Pressing Techniques

Once your designs are printed on the gang sheet, the pressing phase is where all your preparations come to fruition. Proper temperature, time, and pressure settings are crucial to ensuring that the designs adhere effectively to the material. Each substrate has unique requirements, so taking the time to learn about how different materials respond to heat transfer is essential in achieving the best results.

Incorporating a reliable heat press is also vital. It’s important to monitor the heat distribution evenly across the surface, as uneven temperature can lead to incomplete transfers or damage to the design. Post-pressing, allowing sufficient cooling time is equally important, as this helps secure the transfer firmly and enhances the longevity of the graphic on the garment.

Continuously Evolving with the DTF Community

To remain competitive in the DTF printing landscape, it’s beneficial to engage with the broader DTF community. Online forums and social media platforms allow designers and printers to share their experiences, troubleshooting tips, and innovative practices. By connecting with others in the field, you can gain insights into recent advancements, alternative techniques, and creative inspirations that could elevate your work.

Moreover, actively participating in DTF workshops and training sessions can also dramatically improve your skills. Many printing companies offer courses on advanced DTF techniques and gang sheet preparation, which can significantly enhance your understanding and execution of this printing method. Continuous learning and adaptation are key components that will keep your business ahead in this rapidly evolving industry.

Frequently Asked Questions

What is the DTF Gangsheet Builder, and how does it work?

The DTF Gangsheet Builder is a tool that allows users to efficiently arrange multiple designs on a single sheet for Direct-to-Film (DTF) printing. This technique maximizes the use of print media, reduces waste, and enhances production speed by enabling the simultaneous printing of various designs.

How can using gang sheets improve my DTF printing process?

Utilizing gang sheets in DTF printing enhances cost efficiency, reduces production times, and minimizes material waste. By optimizing the arrangement of designs on a single sheet, you can save on ink and media costs while allowing for greater creative experimentation.

What software is best for preparing designs for the DTF Gangsheet Builder?

Popular graphic design software like Adobe Illustrator and CorelDRAW are well-suited for preparing designs for the DTF Gangsheet Builder. These tools offer precise control for arranging designs, aligning them correctly, and managing colors effectively for optimal printing outcomes.

What should I consider when selecting materials for DTF printing with gang sheets?

When selecting materials for DTF printing with gang sheets, prioritize high-quality films and compatible inks designed for DTF printing. This ensures vibrant colors and durable prints, maximizing the potential of your designs during the transfer process.

What pressing techniques are important for ensuring successful design transfer in DTF printing?

Key pressing techniques for DTF printing include applying the correct temperature and time settings based on the substrate, ensuring appropriate pressure during pressing, and allowing sufficient cooling time afterwards. These steps are crucial for achieving strong adhesion and preserving design quality.

How can I engage with the DTF printing community to enhance my skills?

Engaging with the DTF printing community can greatly enhance your skills. Join online forums, social media groups, and industry blogs to share experiences, gather tips, and find resources related to DTF printing and gang sheet techniques. Networking with fellow professionals can lead to valuable insights and creative inspiration.

| Key Points | Details |

|---|---|

| What is a Gang Sheet? | An arrangement of multiple designs on a single sheet for DTF printing, maximizing media use and minimizing waste. |

| Benefits of DTF Gang Sheets | Cost Efficiency, Faster Production Times, Reduced Waste, Increased Creativity |

| Preparing Designs | Use graphic software like Adobe Illustrator; consider canvas size, alignment, and color management. |

| Printing Process | Select compatible inks and high-quality films; regularly calibrate printers. |

| Pressing Techniques | Adjust temperature and pressure; allow cooling time after pressing to set designs. |

| Advanced Tips | Create variations and engage with the DTF community for better insights. |

| Tools and Resources | Online tutorials, industry blogs, and consulting local print shops for advice. |

Summary

The DTF Gangsheet Builder is revolutionizing the printing industry by providing a method to efficiently streamline production while maximizing creativity. By utilizing gang sheets, designers can not only save on materials and costs but also explore new artistic avenues without the constraints of traditional printing methods. This guide highlights the benefits and practical steps to mastering DTF gang sheets, serving as a vital resource for anyone looking to enhance their print production process. Engaging with community resources and continuing to learn ensures that users remain competitive and innovative in their designs.