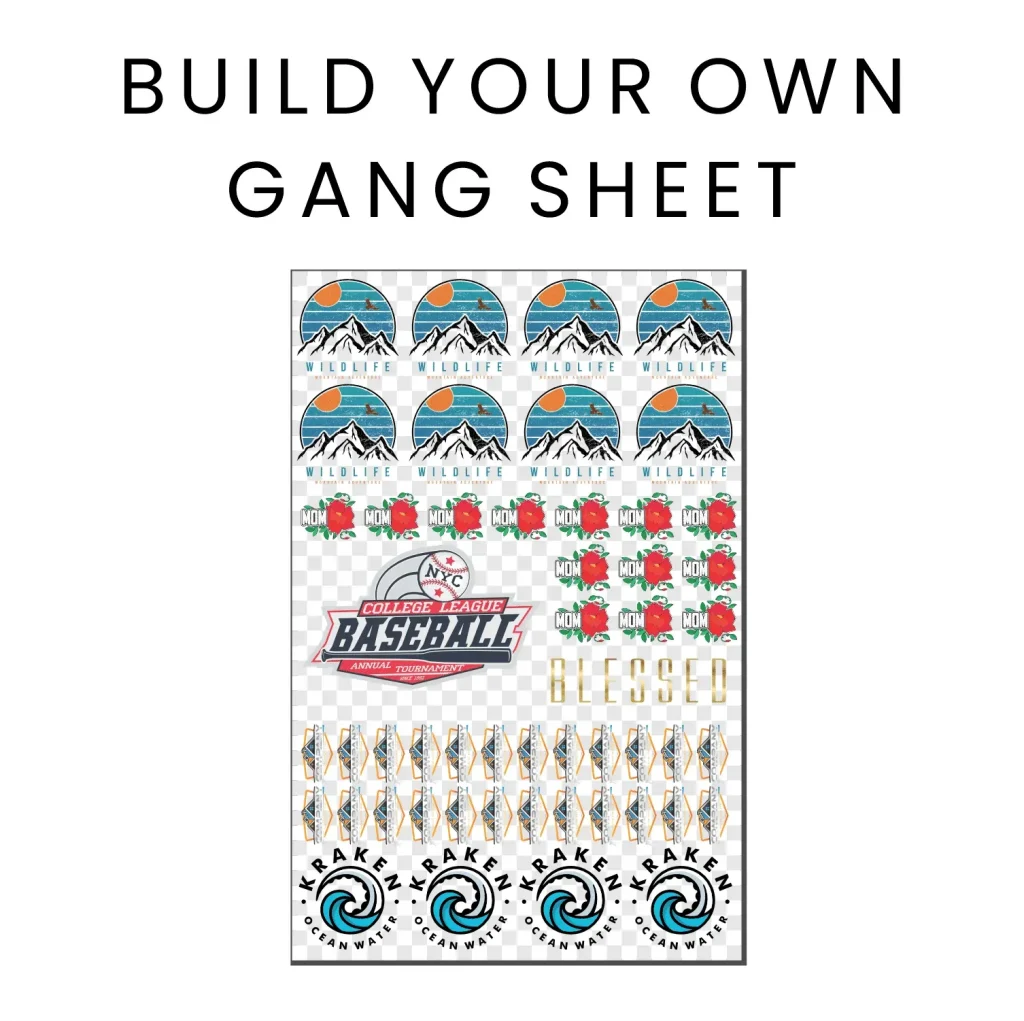

In the dynamic realm of custom fabric printing, the **DTF Gangsheet Builder** stands out as an invaluable tool for both beginners and seasoned crafters alike. This innovative software streamlines the Direct to Film (DTF) printing process, enabling users to create stunning designs efficiently. By harnessing the power of heat transfer printing alongside the adhesive powder application, the DTF Gangsheet Builder allows for seamless integration of multiple designs onto a single sheet. As you embark on your journey into DTF printing, mastering this builder can significantly elevate the quality of your prints. This guide is designed to equip you with essential tips and strategies to optimize your experience and achieve professional-grade results in your custom printing projects.

Delving into the world of DTF printing, also known as Direct to Film printing, opens up a host of creative possibilities using advanced heat transfer methods. The DTF Gangsheet Builder facilitates the creation of custom transfers by efficiently arranging multiple designs on a single film, perfect for crafters wanting to maximize their output. Its unique adhesive application process ensures that designs adhere seamlessly to various textiles, making it an essential part of the printing toolkit. Whether you’re looking to print vibrant graphics or intricate designs, understanding the fundamentals of this technique is key to achieving exceptional results. In this guide, we’ll explore critical aspects of using the DTF Gangsheet Builder to enhance your custom printing endeavors.

Exploring the Fundamentals of DTF Printing

Understanding the fundamentals of DTF printing is essential for anyone looking to excel in custom fabric printing. At its core, DTF (Direct to Film) printing allows users to print intricate designs on a specialized film, which is then applied to fabric using heat and pressure. This method combines the vibrancy of digital printing and the versatility of heat transfer printing. The ability to create stunning prints with rich colors and detail makes DTF printing an appealing option for both crafters and small businesses.

Before jumping into the technical aspects, it’s important to differentiate DTF from other printing techniques. Unlike traditional screen printing or heat transfer methods, DTF printing allows for full-color transfers that can be applied to a variety of fabric types, including cotton and polyester blends. Mastery of the DTF process, including the adhesive powder application and heat curing, can significantly enhance the quality of the final product.

Maximizing Efficiency with the DTF Gangsheet Builder

The **DTF Gangsheet Builder** is a game-changer for optimizing your printing workflow. This user-friendly software allows you to lay out multiple designs on a single sheet, thereby maximizing your material usage and reducing waste. By efficiently utilizing your DTF film, you not only cut costs but also streamline the printing process, allowing for quicker turnaround times on your projects.

Incorporating the DTF Gangsheet Builder into your routine enables you to experiment with different designs while simplifying the adhesive powder application process. With the right settings, you can produce a batch of high-quality prints that save time and ensure consistency across your projects. As you become familiar with the software, you’ll find that it significantly boosts your productivity in custom fabric printing.

Choosing the Best Film for DTF Printing Success

Selecting the right film is crucial for achieving vibrant and durable prints in DTF printing. High-quality DTF film ensures that the ink adheres properly and penetrates the material effectively during the heat transfer process. Using subpar film can lead to issues such as fading or peeling transfers, which can be frustrating for any beginner trying to master this printing technique.

When evaluating different types of DTF film, consider their compatibility with your specific printer and inks. Premium DTF films are designed to work seamlessly with various ink formulations, ensuring optimal adhesion and color accuracy. Additionally, investing in quality films can ultimately enhance the longevity and durability of your printed designs, making them a worthwhile expense in the long run.

Perfecting Printer Settings for DTF Printing

Achieving the best results in DTF printing largely depends on correctly configuring your printer settings. High-resolution settings are essential to ensure that your designs are faithfully represented on the DTF film. Additionally, utilizing the correct color profiles helps in rendering colors that resonate well on the final textile, transforming your digital designs into vibrant physical prints.

Don’t be afraid to experiment with printer settings until you find the perfect combination for your materials. From adjusting ink density to fine-tuning print quality, these tweaks can make a significant difference in the final output. By understanding how your printer interacts with DTF film and ink, you’ll be well on your way to mastering the DTF printing process.

The Importance of Proper Adhesive Powder Application

A key step in DTF printing is mastering the application of adhesive powder, which plays a vital role in the transfer process. When applying the hot melt adhesive powder to the printed film, even distribution is essential for ensuring that the design adheres properly to the fabric. An overapplication can result in thick, clumpy patches that may not transfer correctly, while insufficient powder may lead to weak adhesion.

Using tools such as sifters can help to achieve a consistent layer of adhesive powder on your designs. Pay attention to the evenness of the application, and consider practicing this technique on test prints to refine your skills. Mastery of the adhesive powder application will significantly enhance the quality of your finished products and increase your confidence in DTF printing.

Navigating Common DTF Printing Challenges

Like any craft, DTF printing presents its share of challenges, particularly for beginners. Issues such as poor adhesion, misprints, or color fading can derail your efforts if not addressed promptly. Understanding the common pitfalls in DTF printing is the first step toward troubleshooting, allowing you to rectify problems before they escalate.

Regularly checking and adjusting your settings, such as temperature and print resolution, can prevent many of these common issues. Additionally, consulting online communities or forums dedicated to DTF printing can provide valuable insights and solutions from experienced users. Finding troubleshooting resources is essential for building your skills and overcoming obstacles in your printing journey.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it assist with Direct to Film printing?

The DTF Gangsheet Builder is a specialized software designed to optimize the Direct to Film (DTF) printing process. It enables users to efficiently arrange multiple designs on a single sheet of DTF film, maximizing material usage and minimizing waste. This tool is particularly beneficial for crafters and businesses looking to streamline their custom fabric printing projects.

How do I choose the right DTF film for use with the DTF Gangsheet Builder?

Choosing the right DTF film is crucial for achieving high-quality prints with the DTF Gangsheet Builder. Select premium-quality films that are compatible with your printer and inks. The right film enhances color vibrancy and print durability, ensuring that your custom fabric printing projects yield professional results.

What are the essential settings for my printer when using the DTF Gangsheet Builder?

To achieve optimal results with the DTF Gangsheet Builder, adjust your printer settings to high resolution and use appropriate color profiles that match your design. Experimenting with these settings ensures that the colors printed on the DTF film are vivid and accurately reflect your intended designs, leading to better heat transfer printing outcomes.

How can I master adhesive powder application when using the DTF Gangsheet Builder?

Mastering adhesive powder application is key to successful DTF printing using the DTF Gangsheet Builder. Ensure an even distribution of hot melt adhesive powder on the wet ink by utilizing a sifter. Carefully control the amount of powder applied to avoid thick transfers that may not adhere properly to fabrics.

What is the curing process, and why is it important in DTF printing with the Gangsheet Builder?

The curing process involves applying heat using a heat press to activate the adhesive powder on the printed DTF film. This step is vital to ensure that designs adhere effectively to fabrics. Following the manufacturer’s recommended temperature and duration confidently will prevent issues like peeling or fading, enhancing the longevity of your heat transfer prints.

What common issues may beginners face with DTF printing using the Gangsheet Builder, and how can they be resolved?

Beginners using the DTF Gangsheet Builder may encounter issues such as poor adhesion, fading, or misprints. To resolve these, revisit your printer settings, adjust the print resolution, and experiment with different types of DTF film. Learning to troubleshoot these problems will significantly improve your skills and confidence in DTF printing.

| Key Point | Description |

|---|---|

| Introduction to DTF Printing | Explains the significance of DTF printing and the role of the DTF Gangsheet Builder for beginners. |

| Understanding DTF Basics | Covers the DTF printing process and its unique method of transferring designs to fabric. |

| Choosing the Right Film | Highlights the importance of selecting high-quality DTF film for vibrant and durable prints. |

| Printer Settings | Emphasizes the need for correct printer settings to achieve high-resolution prints and accurate colors. |

| Adhesive Powder Application | Offers tips on applying adhesive powder evenly without overapplying. |

| Curing Process | Describes the heat pressing process for curing the adhesive to ensure proper adhesion. |

| Experimenting with Fabrics | Encourages trying out various fabrics to understand the nuances of DTF printing. |

| Post-Processing Care | Explains the proper care instructions for longevity of prints. |

| Troubleshooting Issues | Identifies common problems beginners face and provides troubleshooting tips. |

| Community Resources | Encourages engaging with online communities for support and learning. |

Summary

The DTF Gangsheet Builder is an essential tool for anyone looking to master the art of DTF printing. It provides a structured method for achieving professional results in custom printing. By understanding the fundamentals of DTF printing, selecting high-quality materials, and mastering techniques such as printer settings and adhesive application, you can significantly enhance your printing projects. Moreover, experimenting with different fabrics, adhering to post-processing care, and engaging with community resources can further solidify your skills. Embrace the creative potential offered by the DTF Gangsheet Builder to elevate your custom printing endeavors to new heights.