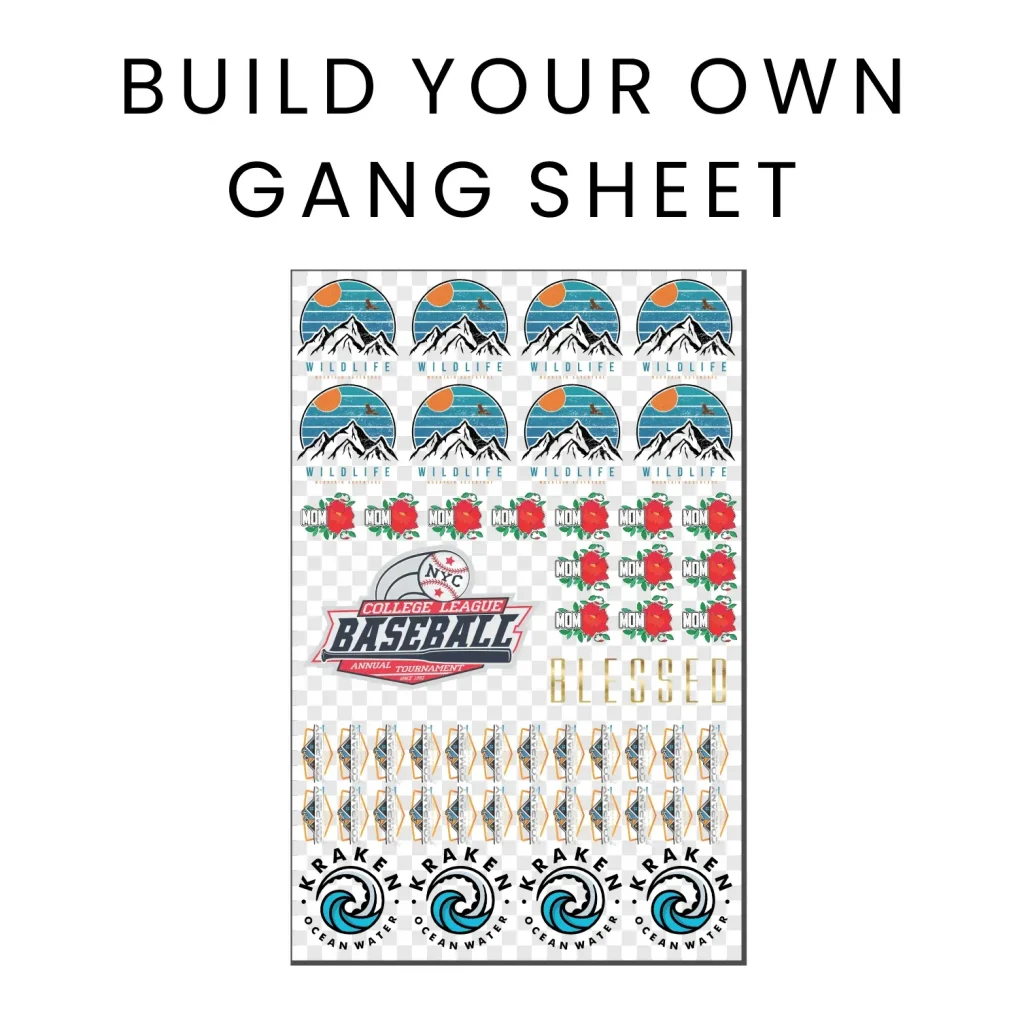

The DTF Gangsheet Builder is revolutionizing the world of Direct-to-Film (DTF) printing, offering users an innovative tool to create stunning apparel designs with ease. By allowing the efficient layout of multiple transfers on a single sheet, this builder maximizes material usage and minimizes waste, making it a game-changer for any printing operation. Whether you are a beginner or a seasoned pro, mastering this builder can open up a world of creativity and cost-saving opportunities. To help you get started, we’ve compiled a collection of essential DTF printing tips that will elevate your skills. From gangsheet planning to optimal printer settings, dive into our guide designed to enhance your DTF design layout and printing techniques while achieving vibrant results.

The DTF Gangsheet Builder, also known as the Direct-to-Film transfer layout tool, is essential for those looking to streamline their printing processes and maximize the efficiency of their resources. This innovative solution allows for the arrangement of several designs on one film sheet, making it an invaluable asset for both beginners and experienced printers. Utilizing gangsheet printing techniques can not only reduce operational costs but also enhance the vibrancy and durability of transferred designs. Understanding the nuances of printer settings and material selection is key to producing high-quality results. As you explore this versatile printing technique, consider how strategic planning can lead to more effective and impactful DTF designs.

Essential Tips for Effective DTF Printing Techniques

Direct-to-Film (DTF) printing has revolutionized how we approach design transfers, particularly for custom apparel. To achieve stunning prints, it is crucial to utilize specific DTF printing techniques that guarantee vibrant, long-lasting results. One essential technique involves ensuring that the ink used is specifically designed for DTF purposes. This not only affects adhesion but also the vibrancy and durability of the print on various fabric types.

Another vital tip for effective DTF printing is to always double-check the printer settings before beginning any print jobs. Settings like DPI (dots per inch) influence the clarity and detail in your prints. A DPI of 720 is recommended to capture intricate designs accurately. Additionally, maintaining equipment calibration is key—ink levels, print heads, and surface cleanliness all contribute to achieving high-quality outcomes. Investing time into getting these technical aspects right will significantly elevate your DTF printing game.

Understanding DTF Design Layout for Maximum Efficiency

A well-thought-out DTF design layout is the cornerstone of successful gangsheet printing. By carefully planning your design placement on the gangsheet, you can minimize material waste and maximize the number of transfers you produce in one go. Utilizing vector graphics is advantageous here; they allow for more flexibility and scalability, ensuring that your designs retain clarity regardless of resizing.

In addition, consider leaving adequate gaps between designs to prevent any overlapping during the cutting process. This is crucial for maintaining quality and ensuring that every print can stand alone without any risk of being ruined. An intentional design layout ultimately saves resources and promotes an efficient workflow in your DTF printing operations.

Mastering Materials for Successful DTF Printing

Choosing the right materials is fundamental in mastering DTF printing. High-quality transfer film is paramount as it directly impacts how well the ink adheres to the fabric. Opt for films that offer strong adhesion and smooth surfaces to ensure clean, detailed results. The type of DTF inks you select also plays a critical role; they should be specially formulated to provide vibrant colors that will last through washes without fading.

Furthermore, DTF powders cannot be overlooked when it comes to successful application. Choosing a powder that melts evenly and adheres properly is essential for achieving a flawless final product. Focusing on these core materials helps alleviate common issues, leading to more efficient operations and higher satisfaction among end users.

Testing and Adjustments: Keys to Quality Control in DTF Printing

Prior to mass production, running test prints is a vital step for quality assurance in DTF printing. Testing allows you to evaluate essential elements such as color accuracy and design placement. By conducting trials, you can easily see whether the colors produced on the fabric meet your expectations, ensuring consistency and satisfaction. This practice saves time in the long run by preventing costly reprints and material waste.

Additionally, adjustments based on test print results can greatly enhance the overall quality of your transfers. Whether it’s tweaking your printer settings for better color fidelity or adjusting heat press timings for optimal application, these small refinements can lead to significant improvements in your final product quality. Remember, consistency is key in DTF printing, and thorough testing ensures reliability in every print.

Optimal Printer Settings for DTF Gangsheet Success

To achieve professional results in DTF printing, it’s crucial to fine-tune your printer settings. Setting the DPI correctly is essential; a resolution of 720 DPI strikes a balance between detail and printing speed, ensuring your designs are replicated with clarity. Additionally, regularly checking printer calibration helps maintain color accuracy and print quality. Regularly clean your print heads and perform maintenance to avoid color discrepancies during production.

Moreover, don’t forget to consider the type of file you’re using during the design process. File formats play a significant role in how print settings are interpreted. High-resolution files produce better results and enhance the details in your DTF prints. Ultimately, navigating through these printer settings will lead you toward consistent, high-quality outputs in your DTF printing endeavors.

Post-Application Care for DTF Printed Fabrics

After successfully applying your DTF transfers, educating your customers on post-application care is crucial for ensuring the longevity of the printed item. Proper care instructions, such as recommending washing in cold water and avoiding harsh chemicals, will help maintain the vibrancy of the print. Additionally, informing them about the dangers of tumble drying can prevent cracking and peeling that may occur due to high heat.

Creating care labels or informational guides can help reinforce these practices among your clientele. Not only does this boost customer satisfaction, but it also encourages repeat business, as customers are likely to return for more products that maintain their quality over time. By prioritizing post-application care, you contribute to a more sustainable practice in the DTF printing world.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it improve DTF printing efficiency?

The DTF Gangsheet Builder is a tool that enables users to create layouts for several designs on a single sheet of DTF film. By utilizing this technology, you can maximize material usage, reduce waste, and streamline the DTF printing process, ultimately increasing efficiency and cost-effectiveness.

What are essential DTF printing tips for beginners using the DTF Gangsheet Builder?

For beginners using the DTF Gangsheet Builder, essential tips include understanding your materials, such as selecting high-quality films and compatible DTF inks. Additionally, focus on DPI settings, calibration of your printer, and strategic gangsheet planning to maximize space and minimize waste.

How should I prepare my designs for optimal use with the DTF Gangsheet Builder?

When preparing designs for the DTF Gangsheet Builder, use vector graphics or high-resolution raster images to maintain clarity. Proper color management ensuring RGB to CMYK conversion is also crucial for achieving accurate colors in your DTF prints.

What role does printer calibration play in the DTF Gangsheet printing process?

Printer calibration is vital in the DTF Gangsheet printing process as it ensures that color discrepancies are minimized. Regularly checking the print head and ensuring correct settings helps produce high-quality prints, maintaining the fidelity of your designs.

What techniques can enhance the application of DTF prints after using the Gangsheet Builder?

To enhance the application of DTF prints, it’s important to set your heat press to the right temperature and pressure for the fabric type. Additionally, monitoring application timing closely can prevent issues like peeling or damage to the transfer, ensuring durability.

What are the best practices for post-application care of items printed with DTF Gangsheet Builder?

Best practices for post-application care include advising customers to wash printed items in cold water, avoiding harsh chemicals or bleach, and suggesting that they refrain from using tumble dryers. This care helps prolong the life of the prints and keeps them looking vibrant.

| Key Points | Details |

|---|---|

| What is DTF Gangsheet Builder? | A tool for creating layouts for multiple transfers on a single film sheet, optimizing material usage and reducing costs. |

| Understanding Materials | Know your films, inks, and powders for successful transfers. Use high-quality materials for the best results. |

| Optimal Printer Settings | Set your printer to 720 DPI and ensure proper calibration to maintain color accuracy and print quality. |

| Design Preparation | Use vector graphics and manage colors effectively to ensure high print quality. |

| Gangsheet Planning | Arrange designs efficiently and leave space between prints to avoid overlapping during cutting. |

| Testing and Adjustments | Run test prints to check color matching and design placement before full production. |

| Application Techniques | Use correct heat press settings and monitor timing closely to avoid damage to prints. |

| Post-Application Care | Educate on washing in cold water and avoiding heat to prolong print lifespan. |

Summary

DTF Gangsheet Builder is an essential tool that allows users to maximize efficiency in the DTF printing process by effectively creating layouts for multiple transfers. Mastering its functionalities can greatly enhance the quality and durability of prints while minimizing waste. To be successful in the DTF printing space, beginners must understand their materials, apply optimal printer settings, prepare high-quality designs, plan gangsheet layouts strategically, and conduct tests to ensure color and placement accuracy. Additionally, employing the right application techniques and post-care instructions will ensure that printed items achieve longevity. For ongoing improvement and support, engaging with DTF printing communities is highly beneficial. As you embark on your DTF printing journey, remember that practice and continuous learning are key to mastering this innovative printing method.