The DTF gangsheet builder is a game-changing tool for apparel printers, enabling efficient planning and batch production. By combining DTF printing and a smart workflow, it helps maximize sheet usage and reduce waste. This software automates layout, alignment, and sizing of multiple designs on a single sheet, ensuring consistent color handling. With integrated color management and print-ready outputs, it supports a smooth handoff to DTF printer software and RIP workflows. Adopting a DTF gangsheet builder can boost throughput, shorten setup times, and improve quality across batches.

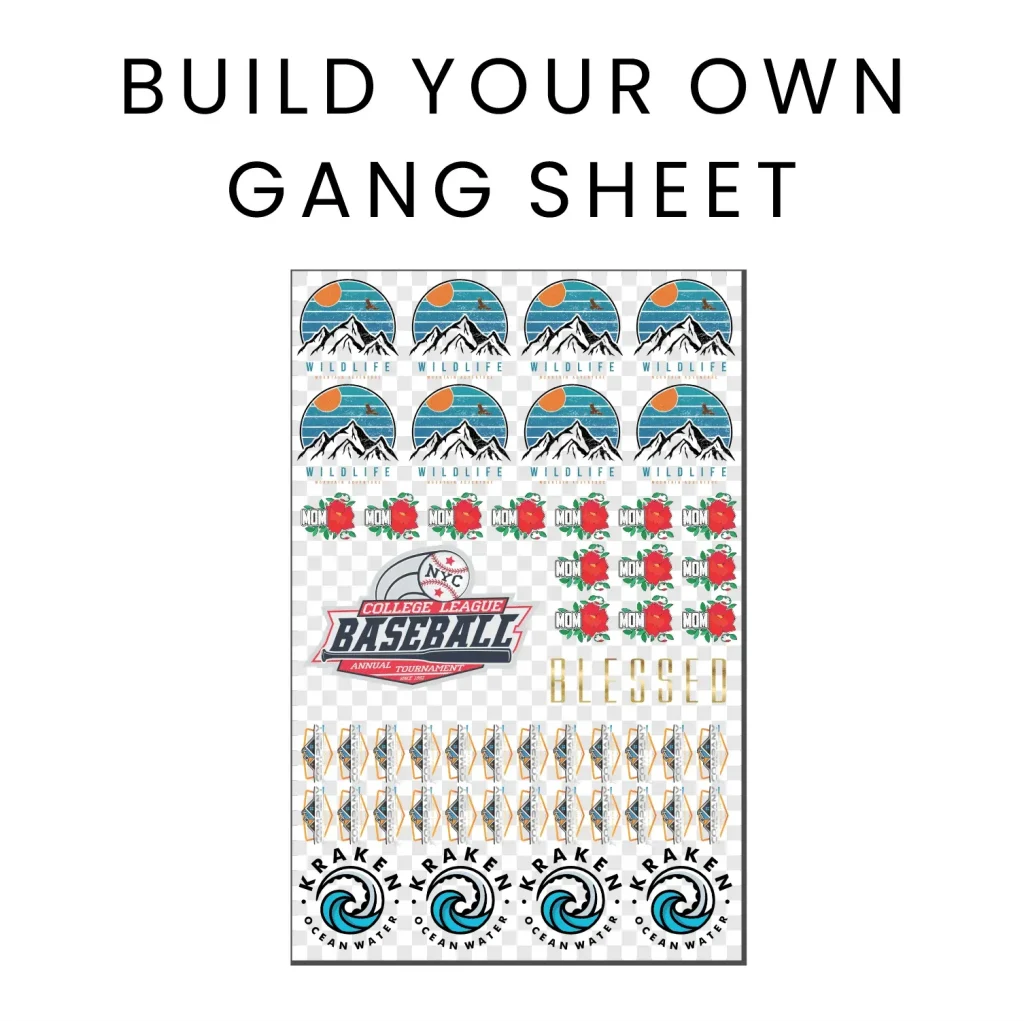

Another way to describe this capability is as a batch-layout automation tool for multi-design sheets used in direct-to-film production. Instead of a single image per pass, it arranges diverse artwork on one film-friendly layout, optimizing margins, bleed, and safe zones. Such a system fits neatly into the DTF workflow by feeding print-ready files into your RIP and printer software, preserving color fidelity across DTF transfer workflows. In practical terms, teams gain faster turnarounds, reduced material waste, and more consistent results when handling multiple designs for the same batch. This approach aligns with broader concepts like automated prepress, color management, and repeatable templates, all hallmarks of modern DTF printing pipelines.

Frequently Asked Questions

What is a DTF gangsheet builder and why is it essential in DTF printing?

A DTF gangsheet builder is software that automates the layout of multiple designs on a single sheet, streamlining the DTF workflow and boosting production efficiency in DTF printing. It maximizes sheet usage, reduces setup time, and ensures consistent margins and color across a batch, making it essential for scalable DTF transfers.

How does a DTF gangsheet builder speed up production in a busy shop?

By auto-arranging designs on one sheet, a gangsheet builder reduces setup time and waste, enabling batch prints and speeding the overall DTF workflow from design to transfer.

What features should I look for in a DTF gangsheet builder?

Key features include auto-layout algorithms, template libraries, bleed/margin/safe-zone controls, color management with ICC profiles, white ink handling, and smooth integration with RIP software and DTF printer software to generate print-ready output.

Can DTF printer software work with a gangsheet builder, and how does that affect the workflow?

Yes. A good gangsheet builder integrates with DTF printer software and RIPs, exporting print-ready output that moves cleanly from layout to print, improving reliability and consistency in the DTF workflow.

How does a gangsheet builder impact color accuracy for DTF transfers?

It uses dedicated color management and ICC profiles to preserve color intent across designs and sheets, supporting white ink layering and color ink workflows for accurate DTF transfers.

What common pitfalls should I avoid when using a DTF gangsheet builder?

Avoid overcrowding sheets, neglecting bleed and safe zones, inconsistent color management, skipping tests, and failing to update templates or plugins; following best practices keeps your DTF workflow efficient and reduces misprints.

| Aspect | Key Points |

|---|---|

| What is DTF printing? | A transfer-based process that prints designs onto a special film, applies adhesive powder, and transfers the image to textiles using heat; supports a wide range of fabrics and enables on-demand customization. |

| DTF gangsheet concept | A gangsheet is a single sheet that holds multiple designs arranged to be printed in one pass; helps maximize printer bed usage, minimize material waste, and reduce setup time. |

| DTF gangsheet builder role | Software that automates the layout: place, align, scale, and optimize several designs on one sheet, with features for bleed, margins, color management, and print-ready output. |

| Benefits of using a gangsheet builder |

|

| How it works in practice |

|

| Key features to look for |

|

| Practical tips |

|

| Integrating into workflow | Shine when used as part of a well-designed DTF workflow: design phase -> prepress (color management and calibration) -> production with consistent heat-time, pressure, and curing standards. |

| Choosing the right tool |

|

| Common pitfalls to avoid |

|

| Case study snapshot | A mid-sized shop printed 250–400 tees per week and adopted a gangsheet builder, achieving 20–30% reduction in setup time and more consistent color across designs. |

Summary

DTF gangsheet builder is a foundational tool for modern on-demand printing operations, providing efficient layouts, color consistency, and scalable batch production. By integrating gangsheet-building workflows with your RIP software, templates, and robust prepress practices, you can reduce setup times, minimize waste, and deliver consistent transfers at speed. For shops aiming to grow capacity while maintaining high quality, adopting this software-driven approach becomes a competitive advantage that translates into happier customers and a healthier bottom line.