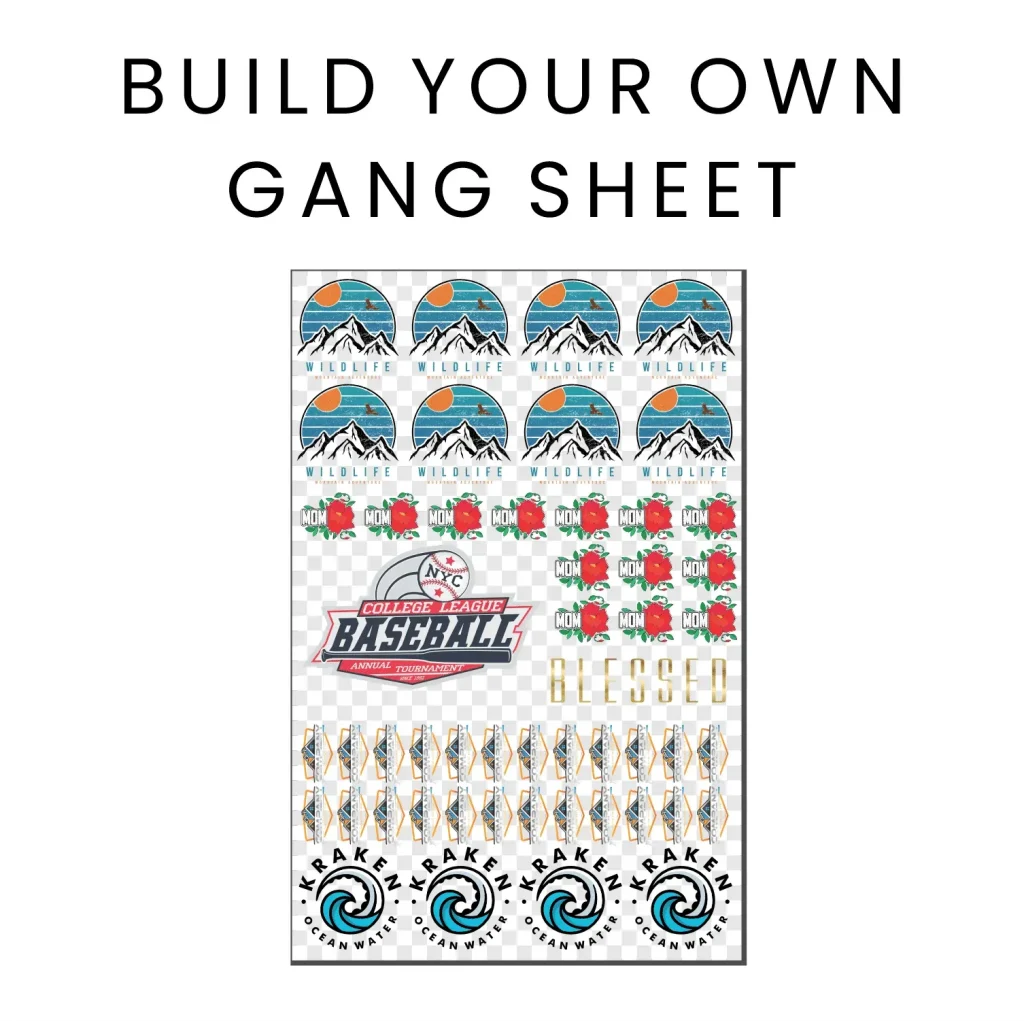

Introducing the DTF Gangsheets Builder, a game-changing tool that takes your DTF printing experience to the next level. This innovative builder enables you to efficiently create gangsheets, allowing multiple designs to be printed on a single sheet of film, thereby reducing waste and maximizing resources. For anyone looking to dive into the DTF printing industry, understanding how to utilize the DTF gangsheets builder is essential to streamline operations and enhance output quality. In this guide, we will explore best practices for DTF gangsheets, answer frequently asked questions (FAQs), and provide you with expert insights on how to achieve stunning results. By mastering the use of a DTF gangsheets builder, you can unlock the true potential of your printing capabilities and stand out in a competitive market.

When discussing the important aspects of Direct to Film (DTF) printing, it’s impossible to overlook the significance of a gangsheets designer. This versatile tool streamlines the process of preparing multiple fabric designs for printing in one go, thus optimizing material usage and reducing costs. As you navigate through the intricacies of DTF design layouts, understanding the best practices can elevate your printing quality significantly. This effective method of printing, often referred to as DTF printing techniques or direct film application, serves as a crucial foundation for creating eye-catching, durable prints. Exploring the most efficient approaches to utilizing DTF gangsheets can transform your printing projects, leading to impressive results and satisfied customers.

Understanding DTF Gangsheets and Their Importance

DTF gangsheets are a transformative tool in the world of Direct to Film (DTF) printing, allowing users to print multiple designs on a single sheet for high efficiency and cost-effectiveness. In DTF printing, where vibrant images are transferred from film to fabric, utilizing a gangsheets builder streamlines the process and minimizes waste. This technique not only enhances production speed but also optimizes the ink and material usage, making it a popular choice among businesses aiming to increase their output without compromising on quality.

The importance of gangsheets cannot be overstated in today’s competitive market. By using a DTF gangsheets builder, printers can achieve diverse design portfolios while maintaining consistency and reducing overall costs. This method is particularly beneficial for businesses that require high volume printing, as it allows multiple design variations to be printed simultaneously. As a result, companies can respond more quickly to customer demands, whether they are producing custom t-shirts or fulfilling large order batches.

Best Practices for DTF Printing with Gangsheets

Adopting best practices when working with DTF gangsheets is essential for optimal results. Key steps include preparing your designs thoroughly in graphic design software like Adobe Photoshop, ensuring that images are in RGB color mode and at least 300 DPI. This attention to detail guarantees that the final print will exhibit the desired vibrancy and sharpness. Additionally, optimizing the layout on the gangsheets is crucial; keeping consistent margins and arrangements will prevent cutting errors and facilitate smoother printing processes.

Another significant best practice is adjusting printer settings correctly. Each printer may require unique adjustments regarding ink types and temperature controls to maximize print quality. Additionally, after printing, applying an adhesive powder evenly on the design is critical to ensure effective transfer to fabrics. Executing each of these best practices can drastically improve the durability and visual appeal of the final product, setting your prints apart from competitors.

How to Use DTF Gangsheets Effectively

Using a DTF gangsheets builder effectively involves a systematic approach to design and printing. Begin by gathering your designs and organizing them based on size and complexity, which allows for a more efficient layout on the gangsheets. Experiment with arrangement techniques that minimize wasted spaces and optimize the number of designs per sheet. This strategic planning not only saves costs but also significantly enhances production flexibility.

Once your designs are laid out, the next step is to ensure that printer settings are adjusted for the specific materials being used. Testing various printer configurations will help you find the optimal settings for ink flow and print quality. After printing, proper curing of the prints is essential; utilizing a heat press with precise time and temperature settings guarantees the longevity of the prints, ultimately providing customers with high-quality, durable products.

Comparing DTF to Other Printing Methods

When considering different printing techniques, DTF printing stands out due to its versatility and efficiency, especially when using a gangsheets builder. Traditional methods such as screen printing can limit the color range and intricacy of designs, often hindering creative freedom. In contrast, DTF printing allows for a more expansive spectrum of vibrant colors and detailed graphics, making it an attractive option for designers and businesses aiming for unique custom apparel.

Another significant advantage of DTF over other methods is its ability to print on a wider range of fabrics. DTF prints work exceptionally well on cotton blends and synthetics, providing a level of durability and vibrancy that other techniques struggle to match. This characteristic is particularly advantageous for businesses looking to expand their product lines without investing in numerous different printing technologies.

Common Questions about DTF Printing

As you delve into DTF printing, several common questions often arise regarding the materials and techniques involved. A frequent inquiry concerns the compatibility of fabrics with DTF printing; the good news is that DTF works well on both light and dark materials, giving printers plenty of flexibility. This capability enables businesses to adapt quickly to various customer preferences, ensuring that they can meet diverse requests for customized apparel.

Another prevalent concern pertains to the durability of DTF prints. Many users wonder how well DTF prints hold up after multiple washes and wear. When executed properly—particularly with correct curing techniques—DTF prints remain vibrant and intact even after extensive use. This reliability is crucial for businesses aiming to offer long-lasting products, maximizing customer satisfaction and repeat business.

Navigating Challenges in DTF Printing

While DTF printing presents numerous advantages, it is not without its challenges. One of the common issues faced by beginners is the learning curve associated with using a DTF gangsheets builder effectively. Proper layout techniques, printer calibration, and curing processes require time and practice to master. However, by committing to continuous learning and utilizing best practices outlined in resources, users can quickly overcome initial hurdles.

Another challenge in DTF printing is ensuring consistent quality across different print runs. Variability in ink quality, film type, or printer settings can lead to inconsistencies that affect the final product. To mitigate these risks, maintaining a checklist of required settings and performing thorough testing before large runs can significantly enhance output quality. Ultimately, being proactive about these common challenges can dramatically improve overall efficiency and success in DTF printing.

Frequently Asked Questions

What is the purpose of a DTF Gangsheets Builder in DTF printing?

A DTF Gangsheets Builder is designed to create layouts that maximize the use of film when printing multiple designs. By allowing several images to be printed on one sheet, it helps reduce waste, saves time, and cuts costs, making it a crucial tool for anyone involved in DTF printing.

How do I optimize my designs for a DTF Gangsheets Builder?

To optimize designs for a DTF Gangsheets Builder, create images using graphic design software such as Adobe Illustrator or Photoshop, ensuring they are in RGB color mode and set at a resolution of at least 300 DPI. This will ensure high-quality prints and prevent cutting issues.

What are best practices for using a DTF Gangsheets Builder?

Best practices for using a DTF Gangsheets Builder include smart design preparation, optimizing layout with consistent margins, adjusting printer settings correctly, applying adhesive powder evenly post-printing, and conducting test runs before large batches to ensure quality.

Can DTF Gangsheets be used on various fabrics?

Yes, DTF Gangsheets are highly versatile and can be used on various fabrics such as cotton, polyester blends, and both dark and light materials, allowing for extensive customization in DTF printing.

How can I ensure the durability of prints created with DTF Gangsheets?

To ensure durability, it’s essential to cure DTF prints properly using a heat press or conveyor dryer according to recommended time and temperature settings. Proper curing helps maintain vibrancy and integrity even after multiple washes.

What should I consider regarding costs when using a DTF Gangsheets Builder?

Costs associated with using a DTF Gangsheets Builder include the expenses for inks, films, and transfer equipment. However, DTF printing often proves to be economical due to its efficiency in mass production, enabling businesses to save money compared to traditional printing methods.

| Key Point | Description |

|---|---|

| Introduction | Overview of DTF printing and the importance of gangsheets. |

| What Are DTF Gangsheets? | Gangsheets allow for multiple designs on one sheet, maximizing efficiency. |

| Key Benefits | Cost-effective, time-efficient, flexible, and reduced waste. |

| Best Practices | Smart design preparation, optimal layout, printer settings, and curing processes are essential for quality output. |

| FAQs | Compatibility with different fabrics, durability, associated costs, and cleaning instructions. |

Summary

DTF Gangsheets Builder is an essential tool for anyone looking to excel in the fabric printing industry. This guide has provided a comprehensive overview of how to effectively leverage gangsheets for printing, highlighting essential best practices, key benefits, and frequently asked questions. Embracing these insights will enhance your production efficiency, reduce waste, and allow you to create stunning custom apparel. As you continue to explore and refine your DTF printing techniques, remember that the foundation of success lies in preparation and quality execution. Dive into the world of DTF printing with confidence, and let your creativity shine!