DTF gangsheets are revolutionizing the way printing is approached in the textile industry, combining efficiency with creativity. As a DTF printing beginner, understanding the optimal use of gangsheets can elevate your projects exponentially, allowing you to consolidate multiple designs onto a single sheet. This technique not only saves on materials and costs but also enhances the vibrancy and clarity of your prints. In this guide, we will delve into essential tips for creating impeccable gangsheets, ensuring that you fully harness the advantages of DTF printing. By mastering textile printing techniques related to gangsheets, you can streamline your process and achieve stunning results.

Within the realm of fabric printing and design, the innovative concept of gangsheets plays a significant role in maximizing efficiency and creativity. By utilizing methods such as grouping designs for simultaneous printing, artisans and businesses can optimize both their time and resources. Known variously as print layouts or design compilations, these formats allow for an economical approach to producing high-quality textile prints. For those exploring DTF printing, understanding how to effectively arrange different images on a single sheet can drastically enhance the outcome of each project. Keywords related to this process, like DTF printing tips and ganging designs, are essential for anyone wishing to delve deeper into this exciting printing technique.

Getting Started with DTF Printing for Beginners

For those new to the world of DTF printing, understanding the basics is essential. DTF, or Direct to Film, is an innovative printing method that leverages heat transfer technology to apply vibrant designs onto a variety of textiles. Beginners should familiarize themselves with the equipment involved, including DTF printers, heat presses, and the specific types of film and inks that yield the best results. Exploring resources like instructional videos or online courses can help demystify the process and build confidence before diving into actual printing.

Moreover, beginners should focus on acquiring quality materials right from the start. Utilizing high-grade DTF films and inks not only impacts the final print quality but also influences the overall printing process. Lower-quality materials can cause a range of issues, including poor adhesion and color discrepancies. Starting with the right materials ensures a smoother learning curve and sets a solid foundation for mastering DTF printing.

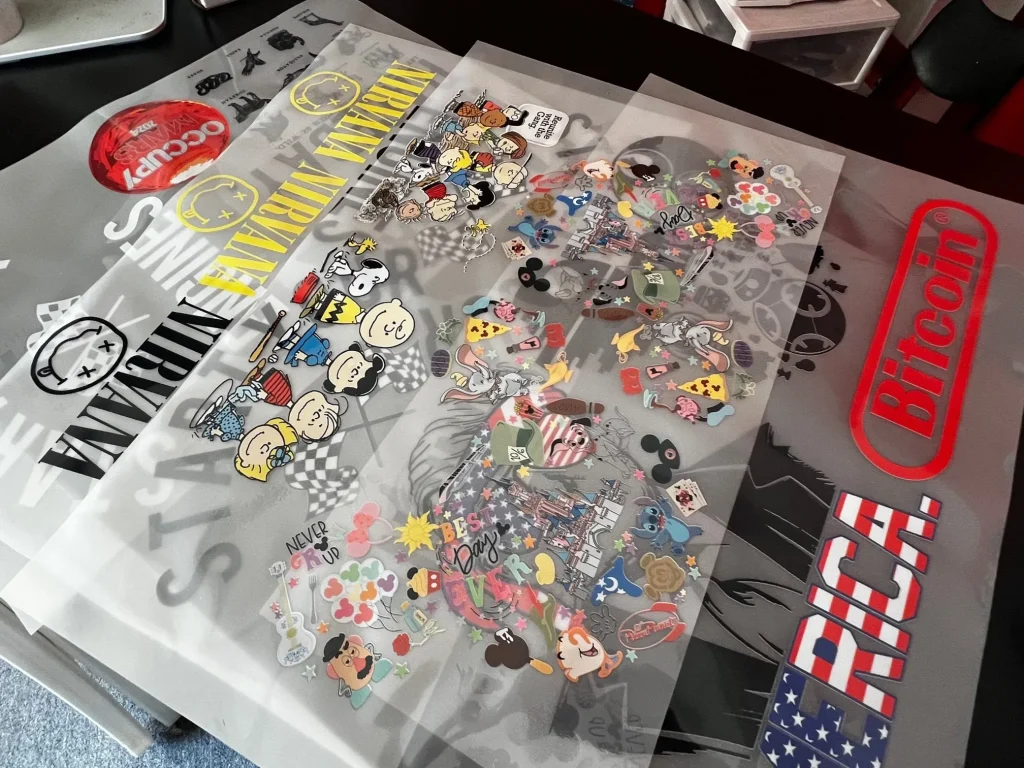

Mastering the Art of Creating Gangsheets

Creating effective gangsheets is a crucial skill for anyone engaged in DTF printing. A gangsheet allows multiple designs to be printed on a single sheet of film, optimizing both material usage and production efficiency. The art of arranging these designs requires strategic planning—consider the size and shape of your graphics and how they will fit together on the film without overlapping, which can adversely affect the quality during the transfer process.

To excel in creating gangsheets, designers should embrace layout optimization tools available in gangsheets builder software. These tools assist in arranging designs seamlessly, ensuring that every inch of film is utilized. Additionally, designers should regularly practice their layout designs before finalizing them for printing. This iterative process can lead to more creative arrangements and can help address potential issues like wasted space or improper spacing between designs.

Best Practices for DTF Printing Tips

To achieve the best results from DTF printing, several tried-and-true tips can be beneficial for both novices and experienced printers. First and foremost, optimizing your digital designs is key. As a best practice, ensure that designs are created in an RGB color profile, which matches the capabilities of DTF printing, and use vector graphics that retain clarity even when resized. This attention to detail can significantly enhance the vibrancy and sharpness of the final print.

In addition to design optimization, it’s important to conduct test prints on various fabrics prior to full production runs. These testing phases allow you to gauge color accuracy and print quality comprehensively. During tests, make sure to adjust printer settings, such as temperature and pressure, specific to the fabric involved. Such adjustments can vary greatly between different textiles, influencing the final aesthetic and durability of the prints.

Design Optimization Techniques for Gangsheets

Optimizing designs for gangsheets is not just about aesthetics; it’s also about functionality. When crafting multiple designs for one sheet, utilize a grid system to arrange designs efficiently. This technique minimizes wasted film and helps visualize how different graphics can align. Furthermore, keeping an eye on the spacing is essential; designs that are too close together may lead to complications during the transfer process, such as bleeding or overlapping.

Moreover, annotation can be a helpful technique during the design phase. Marking different sections of the gangsheets can serve as reminders for different colors and inks to be used. By carefully planning these details, designers can ensure a smoother printing process, enhancing workflow and reducing the chances of errors when producing large quantities.

Understanding the Importance of Test Prints

Test prints are a fundamental step in the DTF printing process, particularly for ensuring the outcome meets quality expectations. Conducting test prints not only ensures that colors appear as intended, but also checks for proper adhesion of transfers on various fabric types. Prior testing can save considerable time and resources, preventing the need for redoing entire batches if a minor issue goes unnoticed.

It’s important to remember that different fabrics react uniquely to DTF prints; therefore, it is advisable to conduct tests on the actual fabric intended for the final product. Various factors, such as the fabric blend and texture, can affect how inks adhere and appear after curing. By embracing test printing, printers can make informed decisions regarding their settings and materials, ensuring high-quality results that satisfy customer expectations.

Advanced Techniques for Curing DTF Prints

Curing is an integral part of the DTF printing process that often determines the longevity and durability of the prints. Advanced techniques in curing include the use of heat presses with precise temperature controls tailored for each type of fabric, as well as experimenting with curing times. Learning to balance these two factors can help achieve the best adhesion, preventing common issues such as peeling or fading.

Additionally, exploring alternative curing methods, like conveyor belt dryers, can be advantageous for higher-volume jobs. These provide consistent temperature and even heat application, resulting in a uniform finish. The right curing technique not only strengthens the transfer but also enhances the vibrancy of the colors, vital for fashion and textile applications where appearance is paramount.

Frequently Asked Questions

What are DTF gangsheets and how do they improve printing efficiency?

DTF gangsheets refer to the practice of arranging multiple designs on a single sheet of DTF film. By maximizing the use of film space, gangsheets improve printing efficiency, reduce material waste, and allow for cost-effective printing by enabling multiple designs to be printed simultaneously.

How can beginners optimize their designs for DTF printing gangsheets?

To optimize designs for DTF printing gangsheets, beginners should convert images to an RGB color profile, use vector graphics for high clarity, and ensure that designs are organized to minimize gaps between them. This optimization is crucial to maintain print quality and to effectively use the available film area.

What are some common DTF printing tips for creating effective gangsheets?

Common DTF printing tips for creating effective gangsheets include selecting high-quality DTF materials, conducting test prints on scrap fabric to check for color accuracy, and adjusting printer settings according to fabric types. These steps help ensure that prints are vibrant and adhere properly.

Why is the curing process important in DTF gangsheets printing?

The curing process is essential in DTF gangsheets printing as it binds the ink to the fabric effectively. Proper curing ensures that the prints are durable, vibrant, and wash-resistant, which is crucial for maintaining the quality of the final product.

What should beginners do to maintain their DTF printer for optimal gangsheets production?

Beginners should regularly maintain their DTF printer by cleaning the print heads and nozzles to prevent clogs, performing routine checks on essential components, and ensuring that the printer is calibrated correctly. Regular maintenance is key to achieving consistent print quality for gangsheets.

Can you explain the significance of using a gangsheets builder in DTF printing?

A gangsheets builder is a software tool that aids in arranging multiple designs on a single sheet of DTF film. This tool is significant as it increases efficiency, reduces material usage, and allows the user to utilize every inch of film space, ultimately leading to better resource management in DTF printing projects.

| Key Point | Description |

|---|---|

| Understanding DTF Printing | DTF printing transfers ink onto fabric using heat, producing high-quality images with detail. |

| What is a Gangsheets Builder? | A tool to compile designs on one DTF sheet, reducing cost and waste. |

| Select Quality Materials | Using high-quality films and inks ensures better color output and adhesion. |

| Optimize Your Designs | Ensure designs are set in RGB and use vector graphics for clarity. |

| Efficient Layouts for Gangsheets | Maximize space by carefully arranging designs without gaps. |

| Conduct Test Prints | Test prints help verify color accuracy and adhesion before finalizing. |

| Adjust Printer Settings | Tailor settings like temperature and pressure to specific materials. |

| Cure Your Prints Properly | Curing ensures inks bind well and prints are durable. |

| Regular Maintenance | Keep your printer clean to ensure consistent quality and prevent issues. |

Summary

DTF gangsheets are a revolutionary tool for those entering the realm of digital textile printing, offering an innovative way to waste less and create more. By implementing the essential tips and tricks outlined in this guide, you can elevate your DTF printing practice to new heights. With an emphasis on quality materials, precise design optimization, and smart layout techniques, this comprehensive approach ensures that each print run is not only efficient but also produces stunning, durable results. Embrace the intricacies of DTF gangsheets, and watch your printing capabilities flourish.