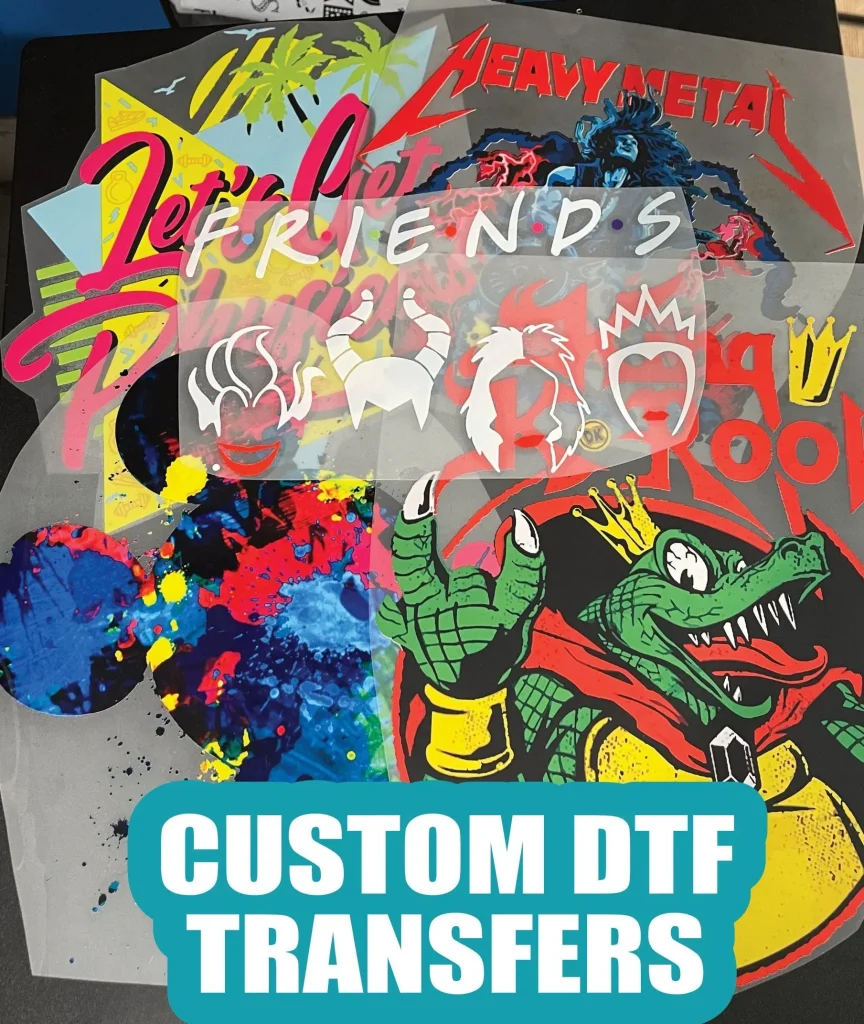

DTF transfers, or Direct-to-Film transfers, have revolutionized the landscape of custom apparel printing with their versatility and efficiency. This innovative printing method uses Direct-to-Film technology to produce high-quality designs that adhere seamlessly to a variety of fabrics, from cotton to blends, making it a favorite among both hobbyists and professional manufacturers. As businesses seek cost-effective solutions without compromising quality, the DTF transfer process stands out for its exceptional ability to deliver vivid prints that withstand wear and tear. Unlike traditional methods, the advantages of DTF printing allow for intricate designs that capture the imagination of creators and consumers alike. In this guide, we will explore the ins and outs of DTF printing, diving into its benefits over methods like sublimation and offering tips that will empower newcomers to thrive in the dynamic world of custom printing.

Direct-to-Film (DTF) methods, often associated with cutting-edge printing technologies, are gaining traction for their remarkable capability in the custom design sector. This approach to printing utilizes advanced film transfer techniques that enable artists and entrepreneurs to create vibrant graphics that effectively bond to diverse material types. The popularity of this technique can be attributed to its flexibility in production, allowing for creative expression across various applications, whether for personal projects or small business needs. Understanding the nuances of the DTF transfer process provides insight into its advantages over other printing techniques, such as sublimation, ultimately paving the way for enhanced creative possibilities in the apparel industry. In this comprehensive overview, we will delve into the fundamentals of DTF printing, offering guidance and best practices for those ready to explore this engaging medium.

Understanding the DTF Printing Process

The Direct-to-Film (DTF) printing process begins with the creation of a digital design, which is printed onto a specialized film using DTF printers. This film has a unique receptive surface that enables high-quality, detailed images to be transferred effectively. The process involves applying a layer of adhesive powder onto the printed film, which is then cured using a heat press. Once cured, the film is ready for transfer onto the selected fabric. The ability to create vibrant colors and intricate designs makes DTF printing a popular choice among custom apparel businesses.

After the initial printing and curing, the transfer process itself is straightforward. The printed film is positioned on the fabric, and heat is applied through a heat press. This heat causes the adhesive to bond with the fabric fibers, allowing the design to adhere securely. One of the significant advantages of this method is its versatility; DTF transfers can be applied to a wide range of fabrics such as cotton, polyester, and mixed blends, which broadens the scope for garment personalization. Understanding this process in detail is crucial for beginners to achieve consistent and high-quality results.

Advantages of DTF Transfers Over Sublimation Printing

When considering different printing methods, it’s essential to understand how DTF transfers compare to sublimation printing. A major difference lies in the type of materials they can be used with. While sublimation is limited primarily to polyester fabrics, DTF printing excels in its adaptability, being compatible with a broader array of fabric types. This capability allows for greater creativity and freedom in design, catering to various customer preferences and expanding product offerings in custom apparel.

Additionally, DTF transfers provide vibrant color reproduction and durability. The technology utilizes a unique adhesive that ensures the print withstands multiple washes without fading, peeling, or cracking. This durability, combined with the ability to print on various fabrics, places DTF as a superior alternative for businesses aiming to offer high-quality products that meet customer expectations. Understanding these advantages helps beginners make informed decisions when selecting printing techniques for their projects.

Essential Equipment for DTF Printing

Investing in the right equipment is critical for successful DTF printing. Essential tools include a high-quality DTF printer capable of producing vibrant designs and a reliable heat press machine for transferring the prints onto fabrics. Additionally, other accessories, such as adhesive powders and special films, are necessary to complete the printing process. For those just starting, it’s wise to balance cost and quality when selecting equipment, as this can significantly impact the overall output and efficiency of your printing operations.

One should also consider the compatibility of different types of inks, as they play a crucial role in achieving the desired print quality. Manufacturers often provide recommendations on the best practices and equipment to use, so researching and seeking advice from seasoned professionals can help newcomers make sound purchasing decisions. As the DTF printing landscape continues to evolve, investing in up-to-date technology can offer a competitive edge.

Key Considerations for New DTF Users

For individuals new to DTF printing, several considerations are crucial for ensuring a smooth and successful entry into this vibrant field. First and foremost is understanding the importance of gang sheets. Gang sheets enable users to print multiple designs on a single sheet, optimizing material usage and minimizing waste, which is a critical cost-saving measure, particularly when starting.

Another key aspect to consider is pricing strategies and understanding the market demand for custom prints. With a diverse offering facilitated by DTF technology, new users should research potential niches and trends within the custom apparel industry. By identifying a target audience and tailoring their product offerings, beginners can establish a successful business model while navigating the early challenges of operating a printing business.

Tips for Maximizing the Impact of DTF Printing

Maximizing the impact of DTF printing involves not just technical proficiency but also strategic planning. New users should experiment with various fabric types to understand the transfer quality and durability differences. This experimentation enables you to recommend specific products to customers and cater to their unique preferences effectively. The adaptability of DTF printing allows for an array of creative designs, making it essential to innovate continually and differentiate your offerings in the marketplace.

Moreover, networking within the industry can open new opportunities for collaborations and sharing best practices with fellow printers. Joining online forums, attending industry trade shows, and participating in DTF workshops can significantly enhance your knowledge base and connect you with valuable resources. Investing time in building industry relationships will not only supplement your technical skills but also broaden the reach of your custom apparel business.

Future Trends in DTF Technology

As DTF technology continues to gain popularity, staying informed about future trends is essential for anyone involved in custom apparel printing. Innovations such as automated printing solutions are beginning to emerge, enabling faster production speeds and higher efficiencies. Companies like Brother are spearheading these advancements, indicating a strong move toward integrating DTF methods with automated processes. This not only reduces labor costs but also enhances the capacity to meet high-volume orders.

Additionally, the ongoing development of eco-friendly materials and sustainable practices in DTF printing is an emerging trend worth noting. As consumers become increasingly environmentally conscious, brands that adopt greener practices, including using eco-friendly inks and sustainable films, stand to gain a competitive advantage. Monitoring these trends will allow DTF users to adjust their strategies effectively and leverage new opportunities in the market, ensuring long-term success.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process involves printing high-quality designs onto a special film, which is then applied to fabric using heat and pressure. This method allows for vibrant, detailed prints on a wide range of materials, making it an ideal choice for custom apparel printing.

How does DTF printing compare to sublimation printing?

DTF printing differs from sublimation primarily in material compatibility. While sublimation works best on polyester fabrics, DTF transfers can be applied to cotton, blends, and other materials, providing greater flexibility for custom apparel printing.

What are the advantages of using DTF technology for custom apparel?

DTF technology offers several advantages including high-quality, vibrant prints that are durable; flexibility in material usage, allowing a range of fabric options; and cost-effectiveness due to optimized gang sheet printing that reduces waste.

What equipment do I need to start with DTF transfers?

To begin with DTF transfers, you’ll need a reliable DTF printer, appropriate inks, transfer film, and a heat press for applying the designs to fabrics. Investing in quality equipment is crucial for achieving the best results in DTF printing.

How can I improve my DTF printing efficiency?

Improving DTF printing efficiency can be achieved by utilizing gang sheets to print multiple designs on a single sheet, ensuring optimal ink usage and reducing waste. Familiarizing yourself with the entire DTF transfer process can also streamline operations.

Are there any recent advancements in DTF technology I should be aware of?

Yes, there have been recent advancements in DTF technology, including innovations from companies like Brother, which aim to enhance automation in printing, and expansions by Eazydtf to meet high demand with faster printing capabilities, making DTF transfers even more accessible.

| Key Point | Description |

|---|---|

| Overview of DTF Technology | DTF printing transfers high-quality designs onto fabrics using heat and pressure, allowing for versatility across different materials. |

| Recent Developments | Innovations from Brother, Eazydtf, and AM.CO.ZA are enhancing DTF technology, making it more efficient and accessible to businesses. |

| Considerations for Beginners | Understanding gang sheets and the differences between DTF and other methods like sublimation is crucial for optimal results. |

| Getting Started Tips | Investing in quality equipment, familiarizing with the process, and experimenting with fabrics are essential for success in DTF printing. |

Summary

DTF transfers are revolutionizing the custom apparel industry with their flexibility and quality. As more businesses adopt this innovative printing technology, understanding its intricacies is vital for success. By recognizing the key features of DTF, such as its material versatility and recent advancements in equipment, newcomers can effectively integrate DTF printing into their operations. As you embark on your DTF journey, remember that investing in good equipment and taking the time to practice will significantly enhance your printing results. Stay engaged with industry trends and innovations to ensure your enterprise thrives in this dynamic market.