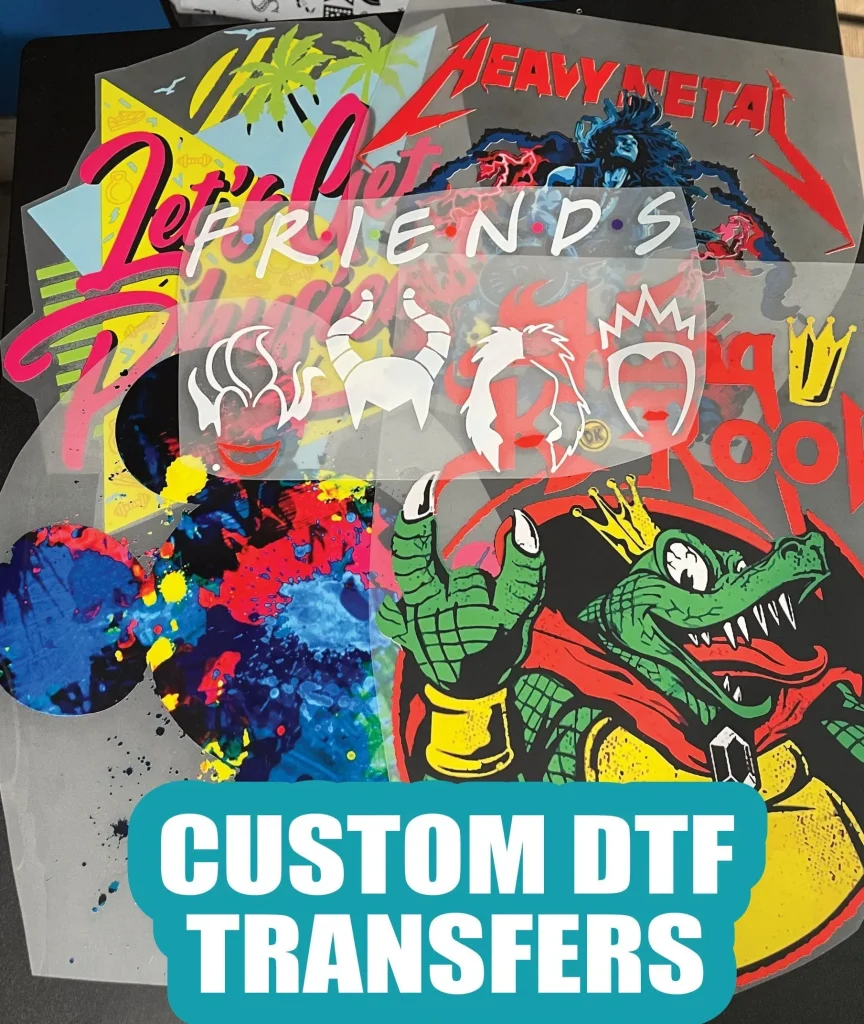

DTF transfers are revolutionizing the world of textile printing, offering an innovative solution for creating vibrant, customizable designs. By utilizing Direct-to-Film (DTF) technology, users can achieve stunning prints with remarkable detail and color accuracy, making it an enticing option for both hobbyists and professionals alike. This cutting-edge method not only simplifies the printing process but also ensures high-quality results on a variety of fabrics, making it an essential technique for modern garment production. To embark on your DTF journey, understanding DTF printing, essential DTF equipment, and the range of DTF transfer supplies is crucial. Mastering how to use DTF transfers effectively opens the door to endless creative possibilities in the fashion industry and beyond.

Direct-to-Film printing, often abbreviated as DTF, is becoming a go-to method for custom garment decoration and personalized textiles. This technique allows for the application of intricate graphics directly onto a specially coated film before transferring them onto various fabric types. With reliable DTF printers and quality inks, users can enjoy flexibility and durability in their designs. Moreover, understanding the necessary DTF transfer supplies, including adhesive powders and heat presses, is essential for ensuring successful outcomes. As demand grows for innovative apparel solutions, mastering the principles of how to use DTF transfers can significantly enhance one’s creative ventures.

Understanding DTF Transfers: A Comprehensive Guide

Direct-to-Film (DTF) transfers represent a revolutionary method in fabric printing that has garnered significant attention from both budding creators and seasoned professionals. This technique involves intricately printing vibrant designs onto a special film that later transfers onto fabric surfaces using precise heat and pressure. The resulting images exhibit exceptional detail and color saturation, making DTF printing an appealing choice for those looking to elevate their textile projects.

One of the key benefits of DTF transfers is their versatility across various fabric types, including cotton, polyester, and blends. This adaptability not only broadens creative possibilities but also allows for greater customization in garment creation. Whether you’re designing promotional wear or personalized gifts, DTF transfers empower users by providing an effective and efficient option for achieving stunning results.

Essential Equipment for Successful DTF Printing

To begin your DTF printing adventure, it’s crucial to arm yourself with the right equipment. A quality DTF printer, typically a modified inkjet printer, lays the foundation for your printing success. Leading brands such as Epson and Ricoh manufacture printers designed specifically for DTF applications. These printers accommodate the unique requirements associated with DTF films and inks, which are tailored to produce vibrant and durable prints on textiles.

In addition to a reliable DTF printer, investing in other essential equipment like heat presses and cutting software is necessary. A heat press ensures optimal temperature and pressure is applied during the transfer process, achieving the best possible adhesion of the design to the fabric. Furthermore, access to graphic design software is vital for creating appealing designs that are tailored for DTF printing, making these tools indispensable for success.

Finding the Right DTF Transfer Supplies

When it comes to DTF printing, having quality materials is non-negotiable. This includes high-grade DTF inks designed with water-based formulations to ensure vivid colors and a soft handfeel after transfer. Unlike traditional inks, DTF inks are flexible and resistant to fading, allowing your designs to maintain their integrity over time.

Equally important is the selection of PET film, a crucial component in the DTF process. This specialized film effectively receives and transfers the printed ink, ensuring that your vibrant designs are accurately and durably transferred to fabric. By investing in premium supplies, you set the stage for successful and stunning printing outcomes.

How to Use DTF Transfers Effectively

Using DTF transfers requires a systematic approach for optimal results. Begin by creating your design using graphic software, ensuring it is appropriately sized for the film and fabric type. Once printed on the PET film, it’s essential to apply DTF adhesive powder before the heat press process. This adhesive acts as the bond between the design and fabric, increasing durability and vibrancy.

Following correct heat press settings is crucial for achieving the best results. Adjust the temperature and pressure based on the type of fabric you are using. Testing the settings on scrap fabric can give you a good baseline before you start with your actual products, ensuring the design adheres properly without damaging the substrate.

Recent Innovations in DTF Printing Technology

As of 2025, the DTF printing landscape is constantly evolving, with exciting advancements enhancing the quality of prints and user experience. Recent innovations focus not only on improving ink properties, such as enhancing color fidelity and reducing fading but also on making DTF printers more user-friendly. This is particularly beneficial for newcomers, enabling a seamless introduction to DTF printing.

Additionally, many manufacturers are now offering starter kits that include essential equipment and supplies for beginners. These kits simplify the purchasing process and provide an all-in-one solution for those eager to start creating. Keeping pace with these innovations can help you capitalize on new trends and maintain a competitive edge in the textile industry.

Tips for Succeeding in DTF Printing

To ensure your success in DTF printing, it is crucial to embrace quality and good practices. Invest in high-quality DTF printers, inks, films, and adhesive powders to secure the best output possible. Also, regularly maintain your equipment to avoid printing issues that could hinder your workflow and output quality.

Conducting test prints prior to production runs is another important step. This allows you to check for color accuracy, adherence, and overall print quality on different fabric types. Finally, remaining informed about the latest trends and practices in the DTF printing sector will provide you with a competitive advantage, allowing you to continuously expand your skillset and product offerings.

Frequently Asked Questions

What are the essential supplies needed for DTF transfers?

To successfully perform DTF transfers, you need several essential supplies: a DTF printer (typically a modified inkjet printer), special DTF inks, PET film (for printing), DTF adhesive powder, a heat press for applying the design, and a computer with graphic design software. These supplies work together to produce vibrant and durable prints on fabric.

How do I use DTF transfers for printing garments?

Using DTF transfers for printing garments involves the following steps: First, design your graphic using software like Adobe Illustrator. Next, print the design onto special PET film using a DTF printer. Apply DTF adhesive powder to the inked film, then cure it before using a heat press to transfer the design onto fabric at appropriate temperature and pressure settings.

What is DTF printing and why is it popular?

DTF printing, or Direct-to-Film printing, is a textile printing method that allows vibrant designs to be printed on a special film and then transferred to fabric. Its popularity stems from its versatility, high-quality print results, and ease of customization, making it accessible for both hobbyists and professionals.

What components make up essential DTF equipment?

Essential DTF equipment includes a dedicated DTF printer, DTF inks, PET film for the transfer process, DTF adhesive powder, a heat press machine, and graphic design software. Each component plays a crucial role in achieving quality DTF prints and successful garment customization.

How does DTF adhesive powder work in the transfer process?

DTF adhesive powder is a critical component in the transfer process. After printing your design onto PET film, you sprinkle the adhesive powder over the wet ink. When heated in a heat press, this powder melts and helps the ink adhere firmly to the fabric, ensuring that the final print is vibrant and long-lasting.

What are the benefits of using high-quality DTF inks?

Using high-quality DTF inks offers several benefits, including vibrant color accuracy, a soft feel on fabrics, and improved durability. Unlike traditional inks, DTF inks provide flexibility and resistance to fading, making them suitable for long-lasting designs that withstand washing and wear over time.

| Equipment/Supplies | Description |

|---|---|

| DTF Printer | A modified inkjet printer designed for DTF applications, crucial for print quality and efficiency. |

| DTF Inks | Water-based inks that provide vibrant prints and a soft feel on fabrics. They are more durable compared to traditional inks. |

| PET Film | A clear film that effectively receives printed ink and withstands the heat transfer process. |

| Adhesive Powder | Powder used to ensure ink adheres to the fabric during the transfer process. |

| Heat Press | Essential for transferring ink from the film to the fabric using heat and pressure. |

| Computer & Design Software | A computer with graphic design software to create high-quality graphics for printing. |

Summary

DTF Transfers have revolutionized the textile printing industry, providing both hobbyists and professionals an accessible way to create custom designs. This process utilizes a specific printer and high-quality inks to ensure vibrant, long-lasting prints on fabric. Essential equipment includes a reliable DTF printer, specialty ink, PET film, adhesive powder for application, and a heat press for the transfer process. As technology advances, DTF printing continues to grow in popularity, empowering users to explore their creativity and stay competitive in the market. By investing in quality supplies and staying updated with industry trends, anyone can successfully embark on a fulfilling journey in DTF Transfers.