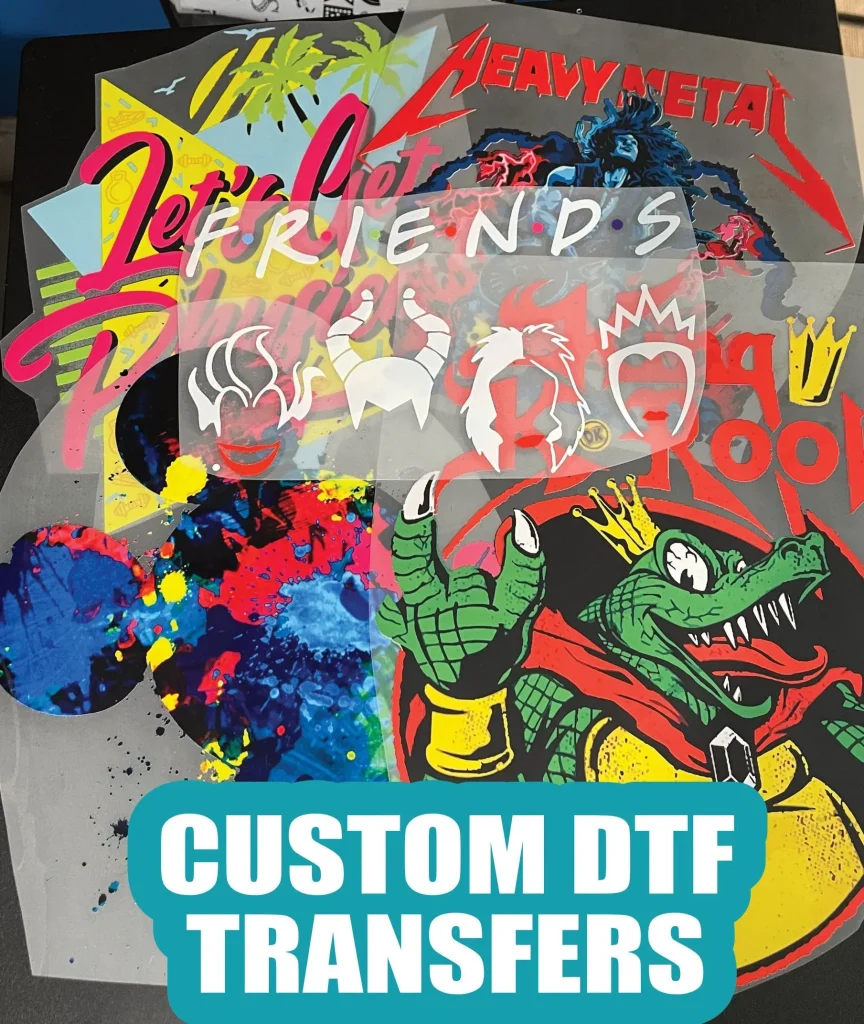

In the realm of custom apparel decoration, **DTF transfers** have rapidly gained recognition as a revolutionary printing method. Leveraging the advanced **Direct to Film printing** technique, this process allows for high-quality fabric printing that produces vibrant designs suited for a variety of fabrics. The **DTF transfer process** utilizes specialized DTF printers that effortlessly apply intricate graphics through a heat-press technique. As a result, creators and designers can achieve stunning visual results that are both durable and versatile, meeting the diverse needs of the fashion industry. This guide will explore everything you need to know about DTF transfers, empowering you to embark on your own fabric printing journeys.

Unveiling the potential of **direct-to-film transfers**, this innovative method of printing has captured the attention of the custom apparel market. Often referred to as DTF printing, this process combines the expertise of inkjet technology with the versatility of heat transfer applications. By using specialized printers to create intricate artworks on transfer films, this approach redefines capabilities in high-quality fabric printing. It presents an exciting opportunity for designers, hobbyists, and businesses to elevate their designs on various textiles. Join us as we delve deeper into the nuances of this cutting-edge printing process and its advantages in the world of garment decoration.

Understanding the DTF Transfer Process

To master DTF transfers, it’s essential to understand the various steps involved in the process. The DTF transfer process begins by gathering the necessary materials, including a reliable DTF printer, transfer film, adhesive powder, and a heat press. Each component plays a crucial role in ensuring that your designs transfer accurately and effectively onto fabrics. Knowing the specifications of your DTF printer and the type of transfer films suitable for your projects is vital for achieving high-quality results.

Once the materials are gathered, the heart of the process lies in printing your designs onto the DTF film. Selecting the right settings on your DTF printer will significantly affect the outcome; ensure that the ink is vibrant and the design is sharp. After applying the adhesive powder to the printed film, curing the design ensures that the powder binds adequately to the ink, setting the stage for the transfer process. This multi-step approach is pivotal in enhancing the durability and quality of the final product.

Frequently Asked Questions

What are the benefits of using DTF transfers for apparel decoration?

DTF transfers offer numerous advantages for apparel decoration, including versatility with different fabric types, high-quality images with vibrant color retention, and exceptional durability. The robust nature of DTF transfers ensures they withstand multiple washes without fading or peeling, making them ideal for everyday wear.

How does the DTF transfer process work?

The DTF transfer process involves several key steps: first, a design is printed onto specialized transfer film using a DTF printer. Next, adhesive powder is applied to the wet ink, which is then cured to bond the materials. Finally, the cured film is placed onto the fabric and heat pressed to transfer the design securely, ensuring lasting quality.

What type of DTF printer is best for high-quality fabric printing?

For high-quality fabric printing using DTF transfers, it’s essential to choose a printer specifically designed for DTF ink compatibility. Many users prefer inkjet models that can handle various resolutions and print sizes, allowing for intricate design details and vibrant colors essential for professional-grade apparel decoration.

Can DTF transfers be applied to all fabric types?

Yes, DTF transfers are compatible with a wide range of fabric types, including cotton, polyester, and fabric blends. This versatility allows for creativity in projects, enabling users to print on different textiles while maintaining vibrant and durable designs.

Are DTF transfers more cost-effective than traditional printing methods?

Yes, DTF transfers can be more cost-effective than traditional printing methods such as screen printing. They require less setup time and fewer materials, which can lower initial investment and production costs, especially for small batch runs or custom designs.

What should beginners know before starting with DTF transfers?

Beginners should research and invest in the necessary equipment, such as a reliable DTF printer and transfer materials. Learning graphic design basics is crucial for preparing artwork, and practicing the DTF transfer process on different fabrics will help ensure quality results. Joining online communities offers valuable support and insights.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers utilize specialized films, inkjet printers, and heat to transfer designs onto fabrics. |

| The DTF Transfer Process | 1. Gather necessary materials (printer, film, powder, heat press). 2. Print the design on DTF film. 3. Apply adhesive powder to the printed design. 4. Cure the design before heat-pressing. 5. Use a heat press to transfer the design onto fabric. |

| Advantages of DTF Transfers | – Versatile with various fabrics. – Produces high-quality, vibrant images. – Durable, resists fading and peeling. |

| Current Trends in DTF Transfers | Growing interest in DTF due to ease of use and advancements in technology. |

| Getting Started with DTF Transfers | 1. Research and invest in equipment. 2. Learn basic graphic design skills. 3. Practice printing and testing. 4. Join online communities for support. 5. Stay updated with industry trends. |

Summary

DTF transfers are empowering creators in the custom apparel market by providing a high-quality and versatile printing solution. This innovative technique allows users to produce intricate designs that can withstand the rigors of everyday wear. With the right materials and a solid understanding of the process, anyone can easily start creating stunning apparel personalized to their style. As demand for DTF transfers continues to rise, it opens exciting opportunities for both seasoned designers and newcomers to express their creativity in fabric decoration.