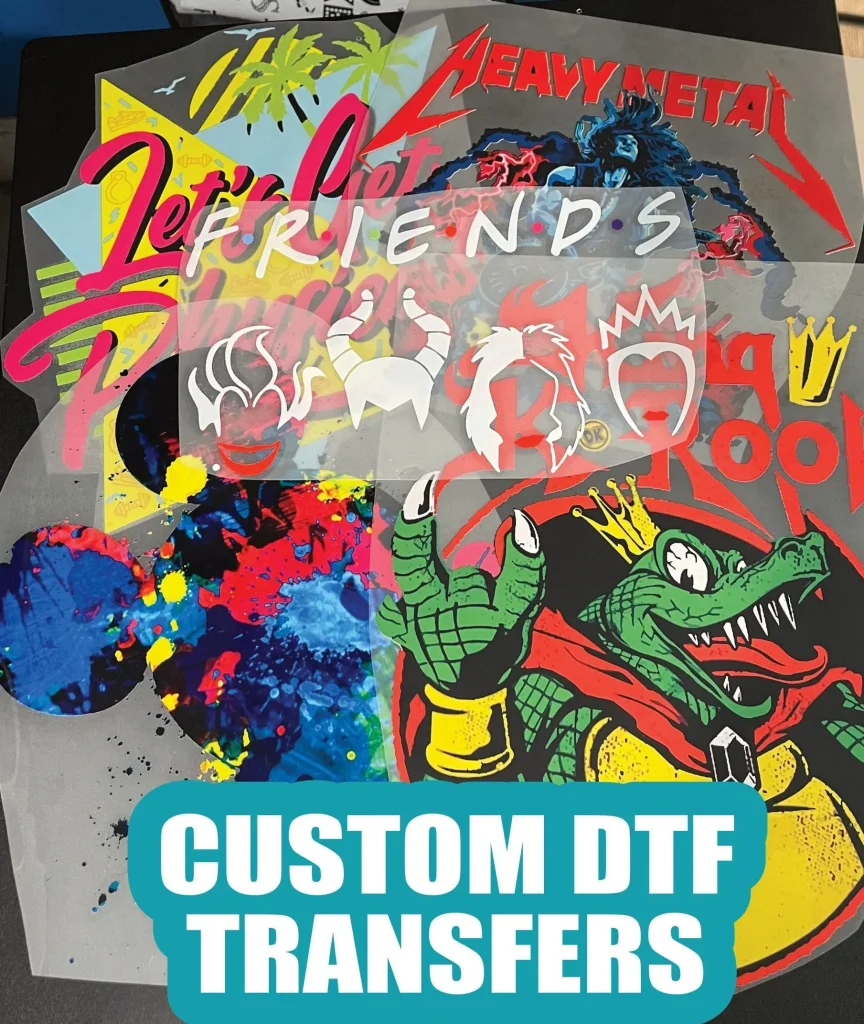

In the dynamic realm of custom apparel printing, **DTF transfers** (Direct-To-Film transfers) are emerging as a game-changing technology that revolutionizes how designs are applied to fabric. This innovative technique allows for vivid, high-quality prints that are durable and versatile enough to be used on a variety of materials, from cotton to polyester. As major players like DuPont and Brother invest in advancing DTF printing technology, the industry is witnessing a shift that not only enhances design capabilities but also increases production efficiency. With its potential to outperform traditional methods like DTG (Direct-To-Garment) printing, DTF is quickly becoming the preferred choice for businesses aiming to deliver unique and personalized apparel. Join us as we delve into the exciting developments in DTF technology and its implications for the future of custom apparel design.

Direct-To-Film transfers, often abbreviated as DTF, signify a transformative evolution in apparel customization techniques. This printing method harnesses advanced technologies to facilitate the application of intricate designs onto textiles, catering to a diverse range of fabric types. As the industry navigates towards greater innovation, DTF is becoming synonymous with efficiency and high-quality outputs. In contrast to traditional Direct-To-Garment methods, DTF printing offers businesses a superior flexibility in their production processes. With the growing demand for personalized clothing solutions, it’s clear that DTF is paving the way for a new era in the custom fabric printing landscape.

Understanding DTF Printing Technology

DTF printing, or Direct-To-Film printing, represents a revolutionary shift in the world of custom apparel. This innovative process involves printing designs onto special films that are then transferred onto fabrics using heat. Unlike traditional methods such as screen printing, DTF technology offers remarkable versatility, allowing for high-resolution designs on various materials including cotton, polyester, and even blends. This is particularly beneficial for businesses aiming to provide a broader range of products to their customers, as the adaptability of DTF printing enables intricate designs without compromising on quality.

The impact of DTF printing extends beyond mere aesthetics; it revolutionizes the production process itself. The ease of application and the ability to produce smaller runs without sacrificing quality means that brands can efficiently cater to niche markets. Furthermore, the durability of DTF transfers ensures that apparel maintains its vibrant appearance even after multiple washes, outperforming many traditional printing options. As a result, DTF technology is becoming an essential tool for custom apparel businesses looking to stay competitive.

Advantages of DTF Transfers Over Traditional Printing Methods

One of the primary advantages of DTF transfers is their superior quality compared to traditional methods like screen and heat transfer printing. DTF technology utilizes specially formulated inks that result in vivid colors and precise details, ideal for complex designs and gradients. This enables custom apparel businesses to expand their design capabilities, providing customers with unique and tailored products that stand out in market saturated with generic designs.

Additionally, DTF printing offers improved efficiency in production. Since the process allows for quick printing and easy application to various fabrics, businesses can significantly reduce turnaround times. This is especially important in today’s fast-paced retail environment, where consumers demand customization and rapid delivery. DTF transfers also minimize waste, as the method requires less ink than traditional screen printing, making it a more sustainable choice for eco-conscious brands.

Comparing DTF Printing to DTG Printing

While both DTF and DTG (Direct-To-Garment) printing serve similar markets, there are critical differences that businesses should consider. DTG printing involves applying ink directly onto garments, which works best for cotton fabrics and simpler color designs. On the other hand, DTF printing can produce vibrant designs on a wider variety of textiles, including synthetic materials, without the restrictions often associated with DTG. This capability opens new doors for customization in fields like sportswear and fashion, where diverse fabric choices are paramount.

Moreover, DTF printing tends to be quicker and more efficient for small to medium-sized production runs. Businesses utilizing DTF technology can achieve faster production times without the extensive setup costs associated with DTG printing. This makes DTF a more versatile option for companies looking to adapt to changing consumer preferences and produce limited-edition items without investing heavily in equipment.

Market Growth for DTF Transfers

The market for DTF transfers is experiencing significant growth, fueled by the increasing demand for personalized apparel. As consumers seek uniqueness in their clothing, businesses are adapting by offering innovative and customizable products. DTF printing allows brands to meet these evolving consumer expectations swiftly and with high-quality results, driving the demand for this technology in the custom apparel sector.

Industry experts predict that the influx of advancements in DTF technology, combined with its cost-effectiveness and quality, will contribute to a substantial rise in its adoption among apparel manufacturers. Companies like DuPont and Brother are heavily investing in research and development for DTF technology, signaling their confidence in its ability to reshape the market dynamics of custom printing.

Sustainability Perspectives in DTF Printing

As sustainability becomes a crucial concern across industries, DTF printing presents itself as a greener alternative to traditional methods. The processes involved in DTF transfers generate less waste and utilize resources more efficiently, contributing to a smaller environmental footprint. This becomes particularly relevant for custom apparel brands aiming to appeal to environmentally conscious consumers, who are increasingly aware of the impacts of their purchasing decisions.

Furthermore, DTF printing’s ability to operate with minimal ink waste aligns with sustainable practices, promoting responsible manufacturing processes. Brands that adopt DTF can not only enhance quality and customization but also position themselves as leaders in sustainable apparel production. As consumer awareness of sustainability grows, businesses that prioritize eco-friendly practices, such as DTF printing, can gain a competitive edge in the market.

The Future Landscape of Custom Apparel Printing

The future of custom apparel printing is bright, with DTF technology leading the charge towards innovation and efficiency. Companies that adapt to this changing landscape will reap the benefits of enhanced productivity and customer satisfaction. As advancements continue to emerge, such as innovative ink formulations and more accessible printing equipment, businesses will need to stay informed about the latest trends to fully leverage the capabilities of DTF technology.

Furthermore, as consumer trends shift towards personalized and high-quality apparel, DTF printing is well-positioned to fulfill these demands. The continued growth of the print-on-demand sector, supported by DTF advancements, will likely see an increase in opportunities for both new and established players in the custom apparel market. Embracing DTF technology not only revolutionizes production capabilities but also aligns business strategies with consumer expectations, ultimately paving the way for sustainable growth in the future.

Frequently Asked Questions

What are DTF transfers in custom apparel printing?

DTF transfers, or Direct-To-Film transfers, are a modern printing method where designs are first printed onto a special film and then transferred to fabric using heat and pressure. This technique produces high-quality, vibrant prints on various materials, making it increasingly popular in the custom apparel printing industry.

How do DTF transfers compare to DTG printing?

DTF vs DTG printing highlights the significant differences in the printing process. While Direct-To-Garment (DTG) printing applies ink directly onto the fabric, DTF transfers first print on film, allowing for more versatility and compatibility with a broader range of fabrics. This makes DTF a preferred choice for intricate designs and multi-material applications.

What materials can be used with DTF printing technology?

DTF printing technology is versatile, allowing for high-quality prints on various materials, including cotton, polyester, and blends. This adaptability makes DTF transfers an ideal option for custom apparel printing across different fabric types.

What are the advantages of using DTF transfers over traditional screen printing?

Using DTF transfers offers several advantages over traditional screen printing, including reduced ink waste, the ability to produce vibrant and detailed designs, and a quicker turnaround time. These benefits make DTF a more efficient and eco-friendly option for custom apparel printing.

Can DTF transfers be used for creating personalized apparel designs?

Yes, DTF transfers are excellent for creating personalized apparel designs. The technology allows businesses to offer customized prints that cater to individual tastes, making it an attractive choice for consumers seeking unique merchandise.

What recent developments are shaping the future of DTF transfers in the custom apparel industry?

Recent developments, such as DuPont’s new pigment inks and Brother’s support for DTF along with DTG, highlight a significant evolution in DTF transfers. These innovations are driving higher quality outputs, faster production times, and broader accessibility for businesses, paving the way for DTF technology’s growing impact on custom apparel printing.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | DTF transfers apply designs onto film that are then transferred to fabrics using heat and pressure, producing durable, high-quality prints on various materials. |

| DuPont’s Innovations | DuPont introduced Artistri DTF pigment inks with new colors and advanced film options that improve production capabilities. |

| Brother’s Dual Support Machines | Brother unveiled machines that support both DTF and DTG printing, enhancing operational efficiency in the custom apparel sector. |

| Insta Graphic Systems | Insta’s DTF heat transfer innovation focuses on vibrant prints and high production efficiency, aligning with industry expectations. |

| Compact A3 DTF Printer by AM.CO.ZA | AM.CO.ZA introduced a user-friendly A3 DTF printer to facilitate entry into the DTF market for new businesses. |

| Sam’s DTF Transfers | Sam’s provides quick printing services, reflecting consumer demand for rapid custom apparel solutions. |

| The Future of DTF Transfers | DTF technology offers businesses agility in design and printing, suggesting a movement away from traditional methods. |

| Implications for Businesses | Investing in DTF technology is crucial for businesses to maintain competitiveness and meet customer demands for personalized apparel. |

Summary

DTF transfers are revolutionizing the custom apparel printing landscape. As this innovative printing method continues to gain traction, it signifies a shift away from traditional techniques, enabling businesses to deliver high-quality, personalized products efficiently. With major advancements in DTF technology by leading companies, the industry is evolving to meet the increasing demands for customization and speed. Understanding and implementing DTF transfers can position businesses at the forefront of this growing market, offering opportunities for innovation and broader customer appeal.