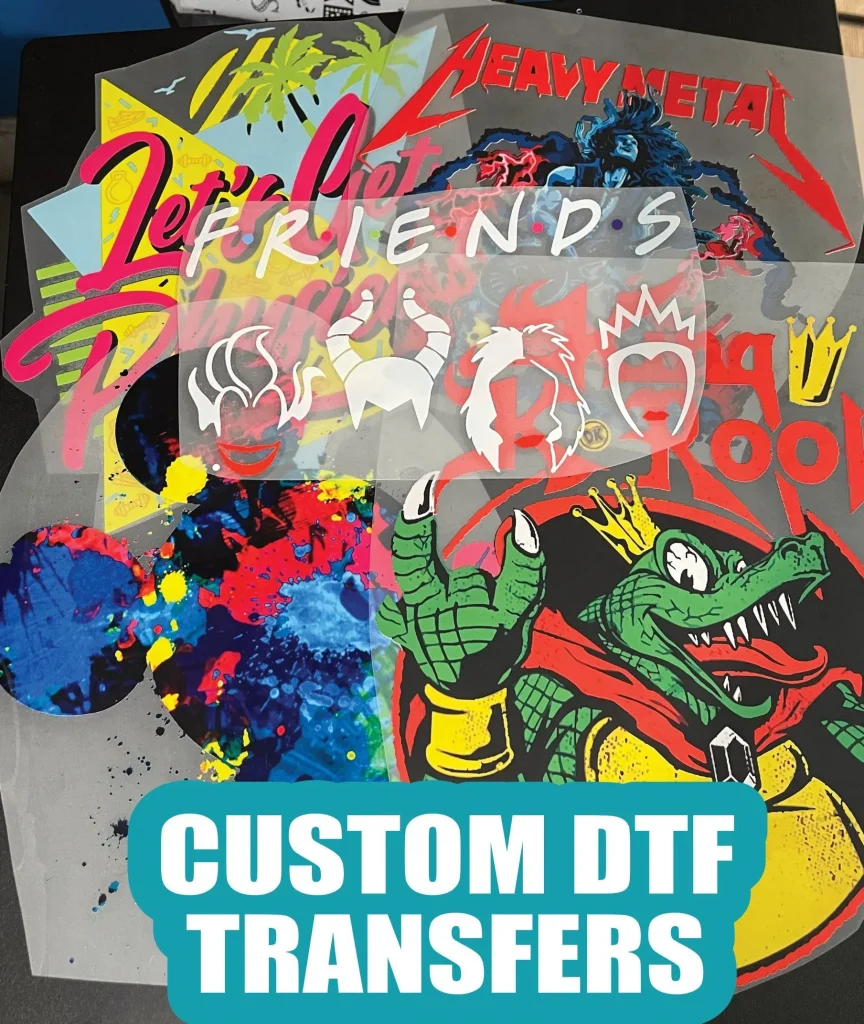

In the bustling world of custom apparel and graphic design, **DTF Transfers**, or Direct to Film transfers, are quickly becoming a game changer. This innovative printing technology allows designers and businesses to craft vibrant prints that were once thought impossible to achieve on fabric. DTF Transfers enable quick and versatile custom printing solutions, catering to the demands of both small startups and larger enterprises. As the landscape of digital design continues to evolve, understanding the mechanics and benefits of DTF Transfers is essential for anyone looking to thrive in the custom apparel market. With a focus on efficiency and quality, this technique is revolutionizing the way we think about custom designs.

When discussing modern printing methods for custom clothing and other designs, terms like Direct to Film transfers, or DTF, are at the forefront of innovation. This technology provides a seamless way to apply high-quality graphics to various materials, enabling endless possibilities for unique creations. As businesses and artists alike embrace these advanced techniques, the demand for striking, durable prints continues to soar. Whether referred to as custom printing or simply graphic design, this approach to fabrication emphasizes speed, affordability, and exceptional results. No matter the terminology used, it is undeniable that the influence of DTF transfers is reshaping the custom design industry.

Understanding DTF Transfers: A Game Changer for Graphic Design

DTF Transfers, or Direct to Film transfers, represent a significant shift in the graphic design landscape. This innovative technology allows designers to print high-quality images onto a special film, which can then be transferred onto various materials. Unlike traditional methods such as screen printing or vinyl, DTF transfers yield vibrant prints that are not only visually striking but also durable enough to withstand regular washing and wear. For graphic designers, this means the ability to create intricate designs without sacrificing quality.

The advantages of DTF printing extend beyond just aesthetics. It simplifies the workflow for designers, eliminating several steps traditionally associated with the custom printing process. By using DTF technology, graphic designers can focus more on their creativity and less on the technical aspects of printing. This transformation allows for a broader spectrum of design possibilities, empowering creators to push the boundaries of custom apparel.

The Versatility of DTF Transfers in Custom Apparel

DTF transfers offer remarkable versatility, making them suitable for a vast array of applications within the custom apparel industry. From sports jerseys to casual t-shirts, the ability to apply these transfers to diverse fabrics significantly expands the creative potential for designers. It opens doors to not just clothing, but also accessories like bags, caps, and home decor items. This flexibility allows businesses to cater to a wide range of customer demands, enhancing their product offerings.

Moreover, the ease of use associated with DTF technology means that even small businesses and individual artists can take advantage of custom printing without the need for large-scale equipment. With no minimum order requirements, designers can operate with lower overhead costs and still produce high-quality apparel. This democratization of custom printing allows for unique, personalized fashion statements that resonate with customers and reflect individual styles.

Quality and Durability: Key Benefits of DTF Transfers

One of the standout features of DTF transfers is the exceptional quality of the prints produced. The process allows for high-resolution images that are rich in detail and vibrancy, which is particularly beneficial for graphics that rely on bright colors and complex designs. When it comes to custom apparel, this print quality becomes a critical selling point, appealing to customers looking for products that stand out.

Additionally, DTF transfers boast impressive durability. The prints are designed to withstand numerous washes without fading or peeling, ensuring that the custom apparel maintains its aesthetic over time. This resilience adds value for customers who seek long-lasting products, establishing trust in the quality of their purchases. As the demand for quality custom apparel continues to rise, DTF technology plays a pivotal role in meeting those expectations.

Empowering Small Businesses with DTF Transfers

The advent of DTF transfers has created new opportunities for small businesses in the custom printing sector. Companies like Sam’s DTF Transfers offer accessible solutions that cater to entrepreneurs and independent designers, allowing them to create unique products without the burden of heavy investment in machinery. By eliminating minimum order requirements, these services empower small businesses to test new designs while minimizing financial risk.

Furthermore, this accessibility encourages more individuals to enter the custom apparel market, fostering a community of creativity and collaboration. Small business owners can leverage DTF technology to differentiate themselves in a crowded marketplace, offering personalized products that resonate with their target audience. This empowerment ultimately fuels innovation in the industry, as more voices contribute to the evolving landscape of custom design.

The Future of Custom Printing: Innovations in DTF Technology

As DTF technology continues to evolve, the future of custom printing looks exceptionally bright. Innovations in printing processes and materials are paving the way for even more advanced capabilities within the DTF realm. This includes further improvements in print quality, faster production times, and even more diverse application areas, making it easier for designers to bring their concepts to life.

The rising trend of sustainability in fashion is also influencing DTF technology. With an emphasis on eco-friendly materials and processes, companies are exploring how to integrate sustainable practices within DTF manufacturing. This shift not only addresses consumer demand for responsible products but also aligns with the growing trend of awareness around environmental impact, ensuring that the custom printing industry can progress responsibly.

Transforming Ideas into Reality with DTF Transfers

The essence of DTF transfers lies in their ability to bridge the gap between creative concepts and finished products. For artists and designers, the frustration of finding the right printing method is alleviated through the simplicity and effectiveness of DTF technology. Whether it’s for a personalized gift, promotional merchandise, or a bold fashion statement, DTF transfers provide a reliable solution for translating ideas into wearable art.

Moreover, the creative potential expands exponentially when designers embrace the capabilities of DTF transfers. They can experiment with different designs, colors, and applications without the constraints traditionally associated with custom printing. This freedom enables them to explore their artistic visions and produce dynamic, market-ready products that cater to diverse consumer preferences.

Frequently Asked Questions

What are DTF Transfers in custom printing?

DTF transfers, or Direct to Film transfers, are a modern method of custom printing that involves printing designs onto a special film, which is then transferred to fabrics using a heat press. This process enables the creation of vibrant, high-resolution prints suitable for various applications in custom apparel.

How do DTF Transfers compare to traditional methods of custom apparel printing?

Unlike traditional methods, DTF transfers produce exceptionally high-quality, vibrant prints and allow for more versatile applications on different fabrics. They also have no minimum order requirements, making them ideal for small businesses and independent designers in the custom printing space.

What are the benefits of using DTF Transfers for graphic design projects?

Benefits of DTF transfers include the ability to create vibrant prints that can withstand washing, versatility across different materials, and flexibility with no minimum order quantities. This makes DTF technology highly favorable for graphic design projects, allowing for rapid production and an array of creative options.

Can DTF Transfers be used for materials other than clothing?

Yes, DTF transfers can be applied to various materials beyond clothing, including bags, hats, and accessories. This versatility allows designers to explore creative expressions across a wide range of custom apparel and promotional items.

What steps are involved in the DTF transfer process?

The DTF transfer process includes creating a digital design, printing that design onto a special film, applying an adhesive powder, using a heat press to transfer the image to the target material, and finally peeling off the film to reveal the vibrant print. Each step is crucial for ensuring a high-quality output in custom printing.

Why are companies like Sam’s DTF Transfers significant in the DTF printing industry?

Companies like Sam’s DTF Transfers are significant because they cater to small businesses by offering no-minimum custom printing options alongside design assistance. Their customer-centric approach simplifies the transition from concept to creation, making DTF technology more accessible to creators and entrepreneurs in the custom apparel market.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs onto a special film that is then heat-pressed onto various materials. |

| High Quality Prints | DTF technology produces vibrant, high-resolution prints suitable for various applications, including clothing and accessories. |

| No Minimum Order Requirements | Companies like Sam’s DTF Transfers offer no-minimum custom printing options, making it accessible for small businesses and individual designers. |

| Versatile Applications | DTF transfers can be applied to a variety of fabrics and surfaces, allowing for creative designs across different types of products. |

| Process Steps | 1. Design Creation 2. Printing 3. Powder Application 4. Heat Application 5. Peeling |

Summary

DTF Transfers are revolutionizing the world of custom design by offering innovative and efficient solutions for creating high-quality prints. This technology not only enhances the aesthetics of custom apparel but also simplifies the printing process with its straightforward steps, enabling creatives to easily bring their visions to life. As demand grows and more companies invest in DTF technology, it becomes imperative for designers and businesses alike to understand and leverage its potential. From the vibrant prints it produces to its flexibility and lack of minimum order requirements, DTF Transfers are setting new standards in the custom printing industry. Therefore, embracing DTF technology is essential for those looking to thrive in the world of custom design.