In the realm of modern printing technology, DTF transfers—short for Direct to Film transfers—have emerged as a game-changer for designers and crafters alike. This innovative method allows for the seamless transfer of vibrant, custom designs onto a wide variety of fabrics, making it ideal for personalized clothing and merchandise. As beginners navigate the exciting world of DTF printing, they will discover numerous advantages, including cost-effectiveness and ease of use, which set it apart from traditional methods. Whether you’re creating custom apparel or exploring new artistic expressions, DTF transfer technology can help unlock your creative potential. Join us as we delve deeper into the essentials of DTF printing, guiding you through the process and benefits that await you.

Direct to Film (DTF) transfers represent an innovative approach in the custom printing landscape, enabling enthusiasts to imprint eye-catching designs onto diverse textiles. This method, often referred to as DTF printing or film transfers, is particularly appealing to beginners seeking to express their creativity without the steep learning curve associated with other printing techniques. With the emergence of user-friendly resources and platforms dedicated to DTF transfer technology, newcomers can easily access knowledge and tools needed to embark on their crafting journey. The advantages of DTF printing, such as its compatibility with various fabric types and efficient transfer process, contribute to its growing popularity among creators. As we explore the intricacies of this method, you’ll see how it can elevate your crafting experience and enhance your projects.

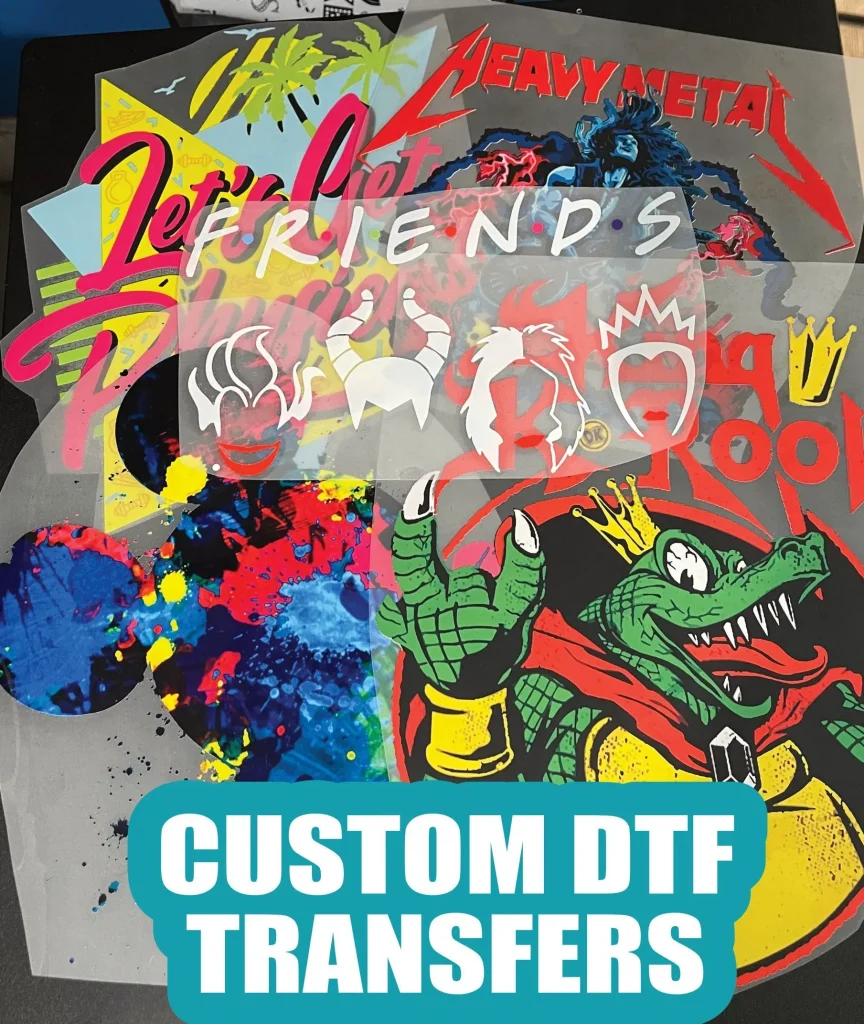

What Makes DTF Transfers Stand Out?

DTF transfers, or Direct to Film transfers, have revolutionized the way we approach fabric printing. Unlike traditional methods, DTF printing leverages a unique technology that allows for high-resolution and vibrant color reproduction on various types of fabric. This versatility means you can create stunning designs not only on cotton but also on synthetic blends, which opens up a wider market for custom apparel and merchandise. The ability to maintain fabric integrity while achieving intricate prints makes DTF a top choice for both hobbyists and professional crafters.

Additionally, DTF transfers are known for their ease of use, especially for beginners. The process involves straightforward steps such as printing the design on a special film, applying an adhesive, and using a heat press to transfer it to the fabric. This accessibility demystifies fabric printing and allows newcomers to produce high-quality products without needing extensive training in complex printing methods.

Understanding the DTF Printing Process

The DTF printing process unfolds in a sequence of manageable steps, making it particularly friendly for those new to crafting. Initially, users create their designs using digital graphic software, which grants them the freedom to customize their artwork fully. Using a specialized DTF printer, the design is printed onto a transfer film, which captures the intricate details and colors of the artwork brilliantly. With the evolution of technology, high-quality DTF printers are increasingly available, making it easier than ever for beginners to dive into their creative projects.

Following the printing step, an essential process involves dusting the wet ink with a hot-melt adhesive powder. This layer is crucial, as it ensures the printed design will adhere properly to the fabric during the heat transfer stage. Once the film is cured under heat to activate the adhesive, it’s ready to be pressed onto the chosen material. This streamlined process keeps DTF printing efficient, allowing users to achieve professional results in a short amount of time.

DTF Printing Advantages for New Users

One of the most compelling advantages of DTF printing is its cost-effectiveness, particularly attractive for beginners. Compared to traditional methods like screen printing or direct-to-garment (DTG) printing, the startup costs for DTF can be significantly lower. New companies entering the market, such as EazyDTF, have begun offering high-quality supplies at competitive prices. This not only helps reduce initial investment but also ensures that beginners can access the materials they need to start their printing journey without breaking the bank.

Moreover, the simplicity of the DTF process eliminates the steep learning curve often associated with other printing methods. For those just getting started, the resources available online, like educational webinars and instructional videos, provide essential guidance. This beginner-friendly approach to DTF empowers participants to experiment with custom designs confidently, fostering creativity while minimizing the intimidation often felt in new crafting ventures.

Exploring the Versatility of DTF Transfers

DTF transfers are incredibly versatile, allowing for the production of a remarkable array of products. From custom t-shirts to uniquely designed home decor items, the applications of DTF printing are virtually limitless. This versatility means that users can create bespoke items suited for different occasions, ranging from personal gifts to promotional merchandise for businesses. The ability to print on various fabric types—including cotton, polyester, and blends—sets DTF apart from other methods, which often have stricter limitations on material compatibility.

Additionally, the customization that DTF offers extends beyond fabric types. Crafters can produce vibrant, full-color designs that cater to specific themes or client requests, making it an invaluable tool for small businesses and individual artists. This adaptability not only enhances the creative process but also positions DTF as a desirable option for those looking to diversify their craft or business offerings.

Recent Innovations Enhancing DTF Technology

The DTF printing landscape is advancing rapidly, thanks in part to innovations that cater specifically to newcomers. Platforms such as DTFPrinter.com have emerged recently, providing a wealth of beginner-friendly resources aimed at simplifying the DTF printing process. These online tools, alongside high-quality printing services, empower individuals to start their DTF journey with confidence, ensuring they have access to the knowledge needed to master this exciting technique.

Furthermore, companies like EazyDTF have made significant strides in enhancing capacity and improving fulfillment speeds, directly impacting the accessibility of DTF supplies. With their commitment to customer service and support, these advancements allow beginners to receive materials promptly, speeding up the learning process and enabling them to kickstart their crafting projects without delays.

Comparing DTF Transfers to Other Printing Methods

When exploring fabric printing options, it’s essential to draw comparisons between DTF transfers and other prevalent methods like sublimation and screen printing. One clear advantage of DTF over sublimation is its superior compatibility with various fabric types. While sublimation requires specific materials, mainly polyester or polymer-coated surfaces, DTF recognizes a broader range of fabrics, making it significantly more versatile for a range of projects.

Cost efficiency further tips the scale in favor of DTF, particularly for small businesses and individual crafters. With lower setup and material costs than traditional screen printing, it allows users to scale production without hefty financial burdens. This aspect of DTF is particularly reassuring for newcomers, encouraging them to take the leap into the world of custom fabric printing with confidence in their investment.

Frequently Asked Questions

What is DTF transfers and how does the DTF printing process work?

DTF transfers refer to the process of Direct to Film (DTF) printing, where your designs are printed onto a special film that can be applied to various fabrics. The DTF printing process includes creating your design, printing it on the film, applying adhesive powder, heat curing, and finally transferring it onto your chosen fabric using a heat press.

What are the advantages of using DTF transfer technology for beginners?

DTF transfer technology offers several advantages for beginners, including cost-effectiveness, versatility across fabric types, and a straightforward application process. This makes it easier for newcomers to create custom designs efficiently and economically.

How does DTF printing compare to other printing methods?

DTF printing stands out against other methods like sublimation and screen printing due to its versatility with different fabric types, lower initial costs, and quicker turnaround times. Unlike sublimation, which only works on polyester, DTF can be used on cotton and blended fabrics as well.

What equipment is needed to get started with custom DTF transfers?

To get started with custom DTF transfers, you’ll need a DTF printer, special transfer film, hot-melt adhesive powder, and a heat press. These are crucial components for the DTF printing process, allowing you to create high-quality and vibrant designs.

Where can beginners find resources and materials for DTF transfers?

Beginners can find resources and materials for DTF transfers at platforms like DTFPrinter.com and EazyDTF, which offer easy access to high-quality printing supplies and educational resources, including webinars and tutorials aimed at newcomers.

Is DTF printing suitable for creating custom apparel and merchandise?

Yes, DTF printing is highly suitable for creating custom apparel and merchandise such as t-shirts, hoodies, and even home goods. Its ability to transfer vibrant designs on various fabric types makes it a popular choice for crafters and small businesses.

| Key Points | Details |

|---|---|

| What is DTF Printing? | A method of printing designs on a special film to transfer onto fabrics, known for vibrant colors and fabric compatibility. |

| Advantages of DTF Transfers | 1. Cost-Effective: Lower initial investment compared to traditional methods. 2. Beginner-Friendly: Easy for novices to learn and use. 3. Quick Turnaround: Faster access to supplies, enhancing project initiation. 4. Versatility: Compatible with various products beyond just fabrics. |

| How DTF Transfers Work | 1. Design Creation 2. Printing on Film 3. Dusting with Adhesive 4. Heat Curing 5. Transfer Process A straightforward process enabling high-quality prints. |

| Recent Innovations | 1. Launch of DTFPrinter.com for beginner resources. 2. Capacity expansion by EazyDTF for faster services. 3. Educational webinars like ‘Discovering DTF’ for skill enhancement. |

| Comparing DTF with Other Printing Methods | DTF printing can handle a wider range of fabric types and is generally more cost-effective than screen printing. |

Summary

DTF transfers represent a remarkable advancement in printing technology, offering accessibility and creativity for crafters and designers alike. This innovative method allows for vibrant and versatile designs, making it a preferred choice among beginners. With the continuous evolution of resources and platforms catering specifically to newcomers, diving into DTF transfers not only simplifies the crafting experience but also opens up endless possibilities for custom creations. Whether for personal projects or small businesses, DTF transfers can transform your artistic vision into reality.