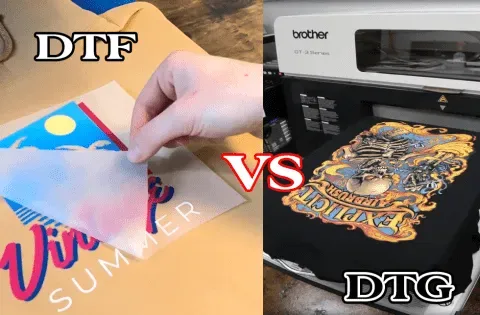

In the dynamic realm of custom apparel printing, the choice between DTF vs DTG is pivotal for businesses aiming to stand out. DTF printing, or Direct to Film, and DTG printing, or Direct to Garment, each present unique attributes that cater to varying printing needs. Where DTG printing excels in delivering vivid, detailed designs directly onto garments, DTF printing thrives in versatility, allowing prints to adhere to a wide spectrum of fabrics. This article delves into the distinguishing features of these printing methods, illuminating factors like durability, cost efficiency, and production speed that could influence your decision. As the demand for custom apparel continues to surge, understanding the nuances of DTF and DTG becomes essential in enhancing operational efficiency and satisfying customer preferences.

The world of custom clothing production has evolved, bringing forward two main competitors: Direct to Film, known as DTF, and Direct to Garment, referred to as DTG. These two printing techniques, while serving the same ultimate goal of creating eye-catching apparel, adopt different methods and technologies. DTF involves printing designs on specialized film before transferring them onto various materials, while DTG involves printing directly on fabric using advanced inkjet technology. Both methods have garnered attention in the printing industry for their capabilities but are often chosen based on specific needs such as print quality, fabric compatibility, and production volume. This exploration will help clarify the disparities and advantages of each technique, making it easier for businesses to align their printing choices with their operational goals.

Comparing DTF and DTG: Key Differences Explained

When diving into the world of custom apparel, it’s essential to understand the fundamental differences between Direct to Film (DTF) and Direct to Garment (DTG) printing. While both methods are celebrated for their unique benefits, they cater to different needs and outcomes. DTG printing employs advanced inkjet technology to apply ink directly onto textiles, allowing for intricate designs and a wide palette of colors. Conversely, DTF printing transfers designs from specially printed films onto various fabric types, making it an incredibly versatile method. Understanding these mechanisms is crucial for businesses aiming to optimize their printing operations.

Moreover, the choice between DTF versus DTG often comes down to the nature of the project at hand. DTF shines in environments that require adaptability, capable of working with both natural and synthetic fabrics. On the other hand, DTG predominantly excels on high-quality cotton, ensuring vibrant colors and long-lasting prints. These differences are not just technical but also influence cost efficiency and production speed, setting the stage for businesses to assess their needs when selecting a method.

Cost Analysis: DTF vs DTG Printing

In terms of financial implications, a thorough cost analysis of DTF versus DTG printing is essential for any custom apparel business. DTF printing generally presents a more attractive entry point, with lower initial equipment costs and reduced maintenance expenses. This affordability can be particularly appealing for startups looking to minimize overhead while venturing into the competitive printing market. Additionally, DTF’s speed in completing batch orders further enhances its cost efficiency, allowing businesses to fulfill larger requests without incurring additional costs.

On the other hand, while DTG printing may come with a steeper initial investment, its capability for high-quality, detailed prints can justify the expense for brands focusing on custom orders or high-value products. The production costs should also reflect the unique qualities that DTG offers, particularly for cotton garments that require a sophisticated appearance. Thus, balancing between purchase price and long-term profitability becomes a strategic decision for businesses aiming to carve a niche in the custom apparel industry.

Durability: How DTF and DTG Prints Hold Up Over Time

Durability stands at the forefront of any discussion about printing methods, with customers increasingly demanding products that withstand the test of time. When comparing the longevity of prints produced through DTF vs DTG techniques, significant differences can be observed. DTF printing is often celebrated for its robust characteristics, allowing for resistance to fading and crackling even after numerous washes. This durability makes DTF particularly well-suited for performance wear or items that are worn frequently, where repeated laundry cycles could significantly impact print quality.

In contrast, while DTG prints have benefited from advances in ink technology, they may not always match the resilience of DTF prints, especially on synthetic materials. The inherent nature of DTG printing requires nurturing to maintain its quality over time, particularly when it comes to vibrant colors on cotton fabrics. Thus, when advising customers on print durability, one must consider their garment’s intended use and the environmental factors that could affect the product in the long run.

Environmental Impact of Printing Methods

As sustainability becomes a key concern for consumers, the environmental impact of printing methods is a pivotal factor in selecting between DTF and DTG printing. DTF printing tends to produce less waste during its processes, as the transfer film can be more efficiently utilized with minimal excess materials. This characteristic positions DTF printing as an appealing option for eco-conscious brands seeking to align their production methods with sustainability goals. In an era where the fashion industry faces scrutiny for its environmental impact, these aspects can greatly influence purchasing decisions.

DTG printing, while capable of using water-based inks that are more environmentally friendly than traditional inks, can generate more waste than DTF due to its printing approach. However, advancements in technology continue to improve both methods, making them increasingly sustainable choices. Companies that prioritize eco-friendliness can benefit from understanding these nuances, as they can effectively communicate their commitment to sustainability while offering high-quality products to their customers.

Market Trends: The Growing Popularity of DTF in Custom Apparel

With the evolution of the custom apparel landscape, market trends are revealing a growing preference for DTF printing over the traditionally established DTG method. This shift is largely attributed to DTF’s market adaptability—being able to print on various substrate materials—including both synthetic and natural fabrics. As businesses continuously look for ways to cater to diverse customer needs, embracing DTF technology allows them to enhance their product offerings and stay relevant in a competitive market.

Furthermore, the escalation in bulk order demands amplifies DTF’s appeal due to its efficient production capabilities. Many businesses are leveraging the advantages of DTF printing to meet growing industry trends, reflecting a willingness to invest in versatile solutions that boost operational efficiency. Entrepreneurs are increasingly embracing hybrid business models that incorporate both DTF and DTG options, allowing them to cater to a broader customer base while maximizing their operational flexibility.

Choosing the Right Printing Method for Your Needs

Ultimately, selecting the optimal printing method between DTF and DTG for your specific project requires careful consideration of various factors. Businesses should weigh budget constraints, the intended fabric types, production volumes, and the desired print quality. Each method has its strengths and weaknesses; the decision should reflect not just the current demands but also future aspirations and market trends. Engaging with both printing methods places businesses in an advantageous position to adapt as the custom apparel market continues to evolve.

As technology advances, the potential for integrating both DTF and DTG approaches into a single business strategy becomes more viable. This integration can lead to increased production efficiency and customer satisfaction by allowing businesses to deliver quality products tailored to their audience’s preferences. Understanding the nuances of each printing method ensures that decision-makers can confidently navigate the custom apparel landscape and meet the diverse needs of their clientele.

Frequently Asked Questions

What are the main differences between DTF vs DTG printing methods?

DTF (Direct to Film) printing involves printing designs onto a special film that transfers onto fabric, while DTG (Direct to Garment) printing applies ink directly onto the garment. DTF is versatile, working on various materials, and is faster for batch production, whereas DTG excels in detail and vibrancy on natural fibers like cotton.

Is DTF printing more cost-effective than DTG printing for startups?

Yes, DTF printing typically presents a more economical option for startups due to lower initial equipment costs and maintenance. Businesses can also produce multiple designs simultaneously, offering quicker turnaround times compared to DTG printing.

Which method is more durable, DTF vs DTG printing?

DTF printing is generally recognized for its superior durability, especially on synthetic fabrics, often outlasting DTG prints in washability. This makes DTF a preferred choice for performance apparel or items requiring frequent washing, while DTG offers rich colors predominantly on cotton.

Can DTF printing be used on any type of fabric compared to DTG?

Yes, DTF printing is highly versatile and can be applied to various materials including polyester, nylon, and cotton blends, making it suitable for a broader range of custom apparel. In contrast, DTG printing is best suited for natural fibers, particularly cotton.

Do DTF prints require any special preparations before application compared to DTG prints?

DTF prints need a heat transfer process to bond them onto textiles, while DTG printing directly applies ink to the garment without additional transfers. This allows DTF to store prints for later, while DTG is often produced on demand.

How do environmental impacts compare in DTF vs DTG printing?

DTF printing is typically seen as more environmentally friendly due to lower waste production during manufacturing. While both methods can use eco-friendly inks, DTF’s efficiency in material use appeals to sustainability-focused brands more than DTG.

| Key Factors | Direct to Garment (DTG) | Direct to Film (DTF) |

|---|---|---|

| Printing Method | Uses inkjet technology to print directly onto fabric. | Prints designs onto a film, which is then heat transferred to fabric. |

| Ideal Fabric Types | Best for natural fibers like cotton and cotton blends. | Compatible with a variety of materials including polyester, nylon, and cotton blends. |

| Print Quality | Excellent for vibrant colors and detailed designs. | Produces vibrant colors with high clarity for intricate designs. |

| Production Speed | Usually slower, prints one item at a time. | Quicker, can print multiple decals at once. |

| Cost Efficiency | Higher initial equipment cost and maintenance. | Lower initial cost and quicker production times for larger orders. |

| Durability | Strong on cotton but less durable on synthetics. | Excellent longevity and flexibility, especially on performance fabrics. |

| Environmental Impact | Uses relatively eco-friendly inks but can produce waste. | Lower waste production, appealing to eco-conscious consumers. |

| Market Trends | Preferred for high-quality, custom designs. | Gaining popularity for mass productions and bulk orders. |

Summary

DTF vs DTG printing methods has revolutionized the custom apparel industry, each offering distinct advantages tailored to specific business needs. DTF, with its ability to print on diverse materials and faster production speeds, caters well to the demands of bulk printing, while DTG excels in delivering high-quality, intricate designs primarily on cotton fabrics. As businesses weigh factors such as cost efficiency, durability, and environmental impact, understanding the nuances between DTF and DTG is paramount. This knowledge empowers companies to make informed decisions that align with their operational goals and customer expectations, thus positioning themselves competitively in an ever-evolving market.